Automatic air duct feeding device for compressor top covers

An automatic feeding and airway technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of limited feeding efficiency of airway and increase the output of manpower, so as to reduce the output of manpower and improve the work. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

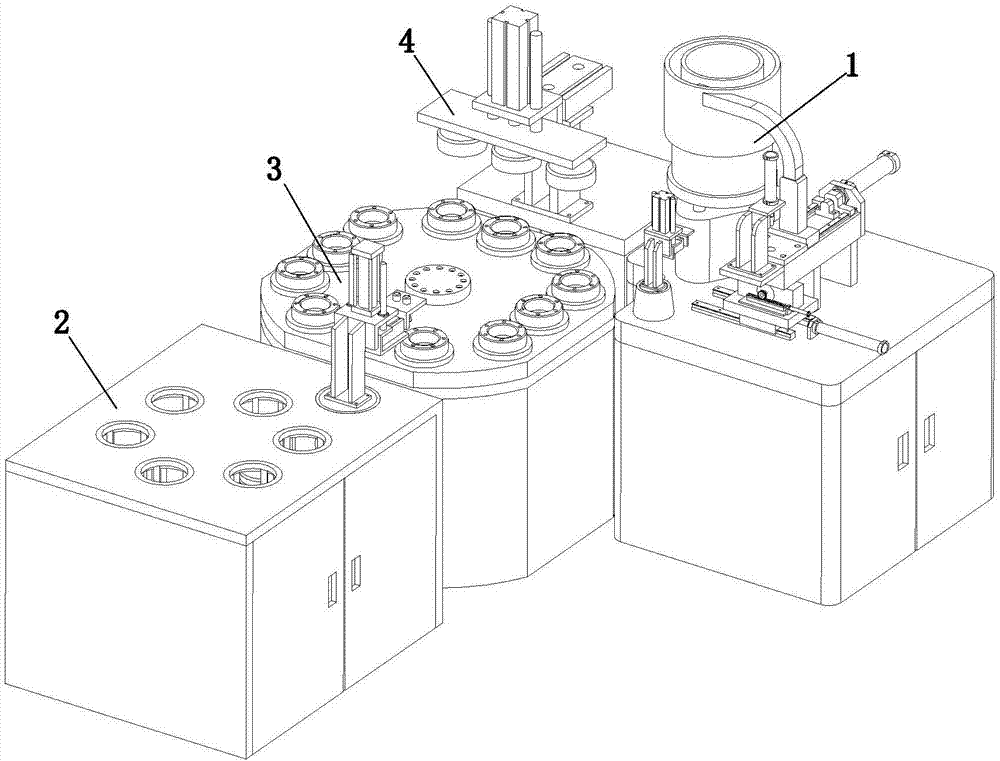

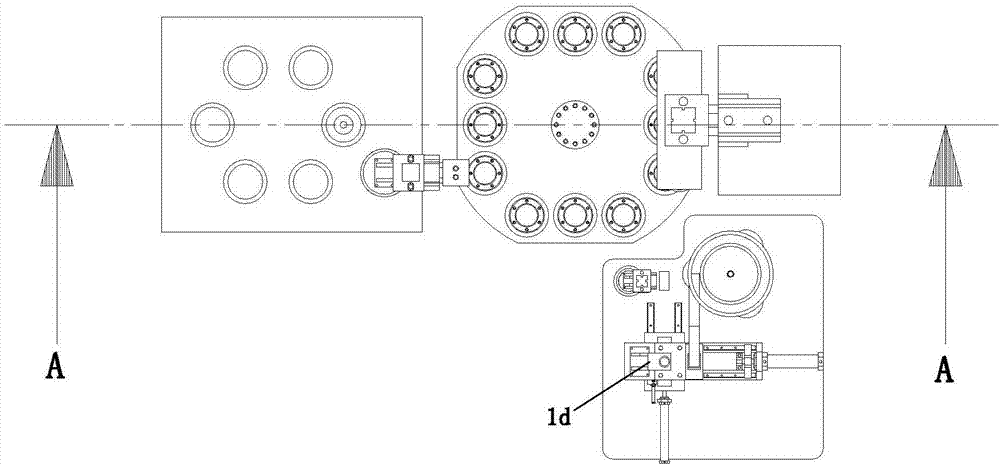

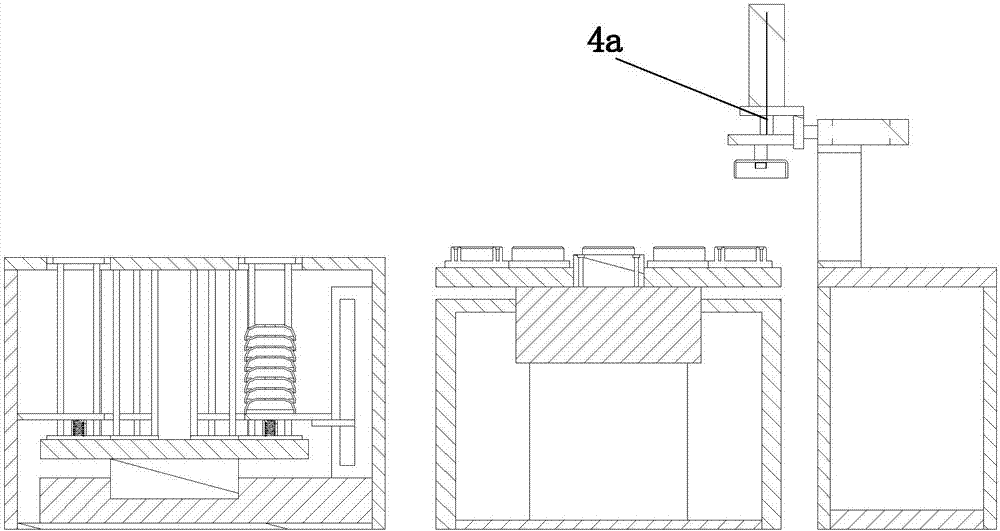

[0036] refer to Figure 1 to Figure 17 A kind of automatic loading and assembling machine of air guide tube of compressor upper cover shown, comprises air guide tube feeding device 1, compressor upper cover feeding device 2, compressor upper cover carrying device 3 and automatic assembly device 4, described compressor upper cover The carrying device 3 includes a carrying work cabinet 3a, a loading turntable 3b, a drive mechanism and several fixtures 3c arranged in a rectangular distribution on the loading turntable 3b for holding the upper cover to be assembled. There are upper cover loading station, air duct feeding station and assembly station. When the loading turntable 3b is in a static state, the upper cover loading station, air duct feeding station and assembly station all stay with jigs 3c, the compressor up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com