A string and method for downhole oscillation distribution process of water injection well

A technology for process pipe strings and water injection wells, which is applied in wellbore/well components, earthwork drilling, wellbore flushing, etc., can solve problems such as increased crude oil cost, installation difficulty, pollution, etc., and achieves improvement of pipe string vibration environment and tools The effect of simple and reliable structure and simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

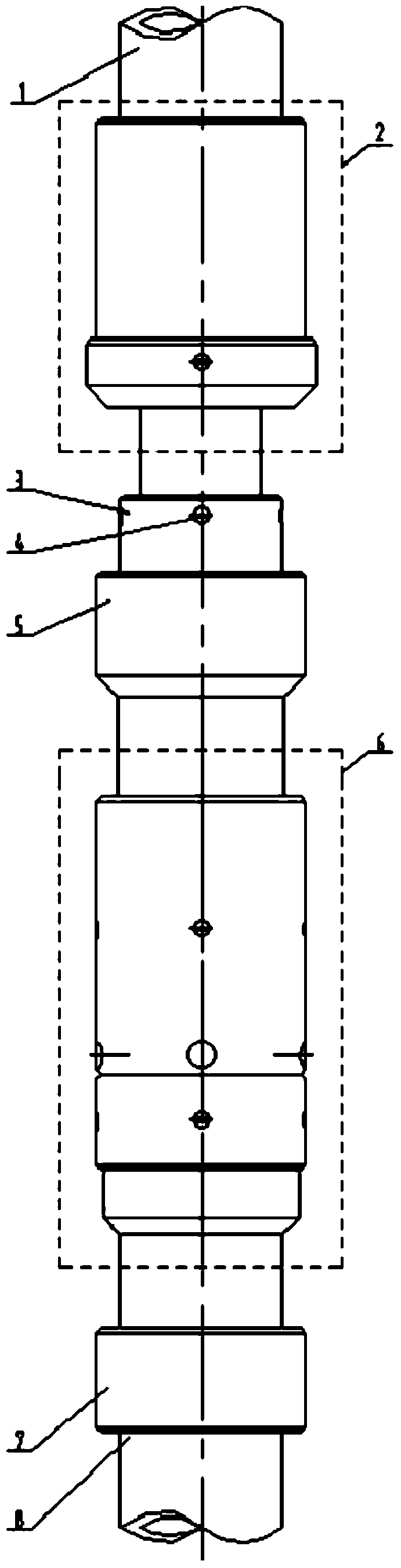

[0030] according to figure 1 , a downhole oscillating dispensing process tubing string for a water injection well, comprising an upper tubing 1, an oscillating buffer 2, a variable buckle joint 3, an anti-loosening nail 4, a pup joint 5, an oscillation generating water distributor 6, a coupling 7 and a lower tubing 8 , the upper end of the vibration buffer 2 is threaded with the upper oil pipe 1, the lower end is threaded with the variable button joint 3, and fixed with a lock nail 4, and the lower end of the variable button joint 3 is sequentially threaded with the short joint 5, the vibration generating water distributor 6, and the Hoop 7 and lower oil pipe 8.

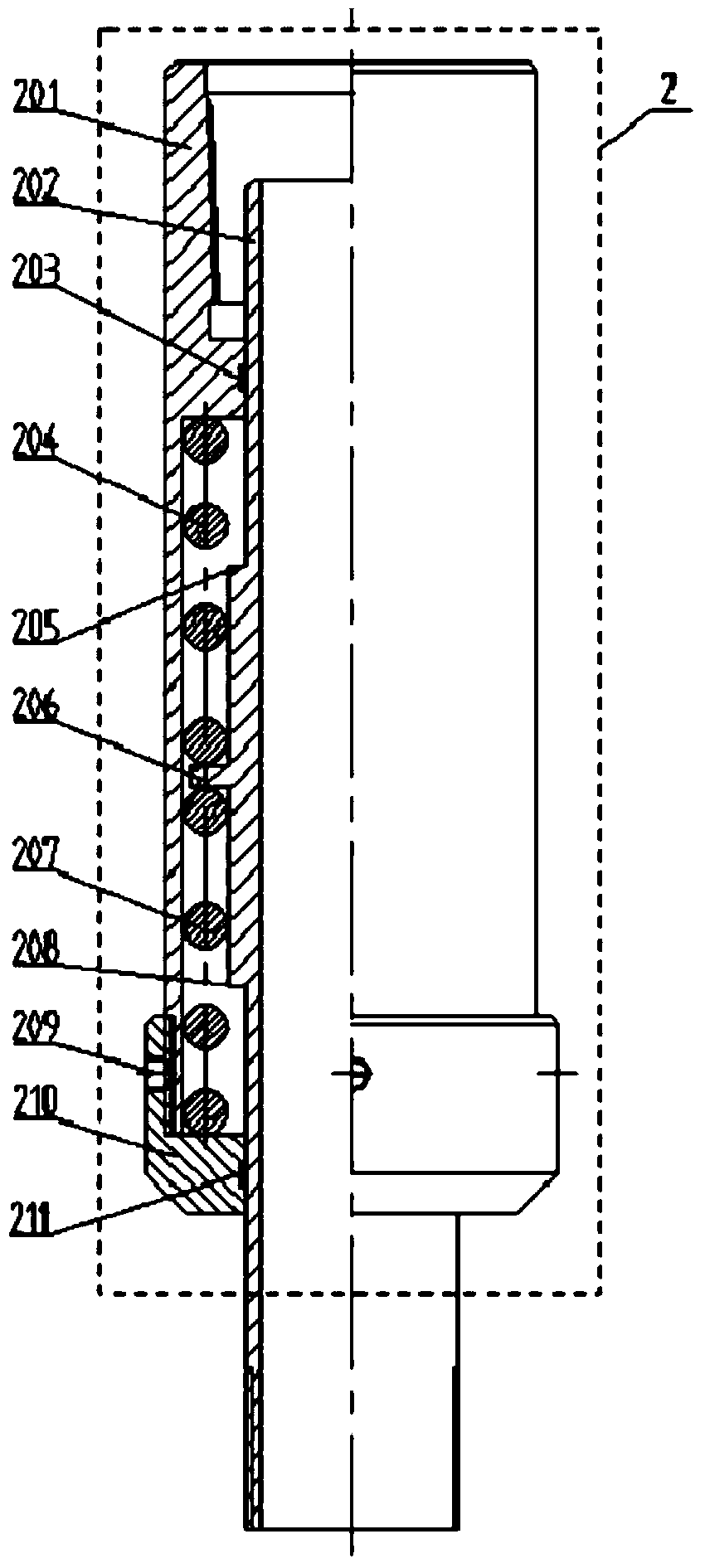

[0031] according to figure 2 , the vibration buffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com