Method for installing derived type built-in strain gauge for building test piece

An installation method and technology of strain gauges, which are applied in the direction of measuring devices and instruments, can solve the problems of large damage, large strain gauge damage, and easy damage of strain gauges, and achieve the effect of preventing short-circuit due to moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

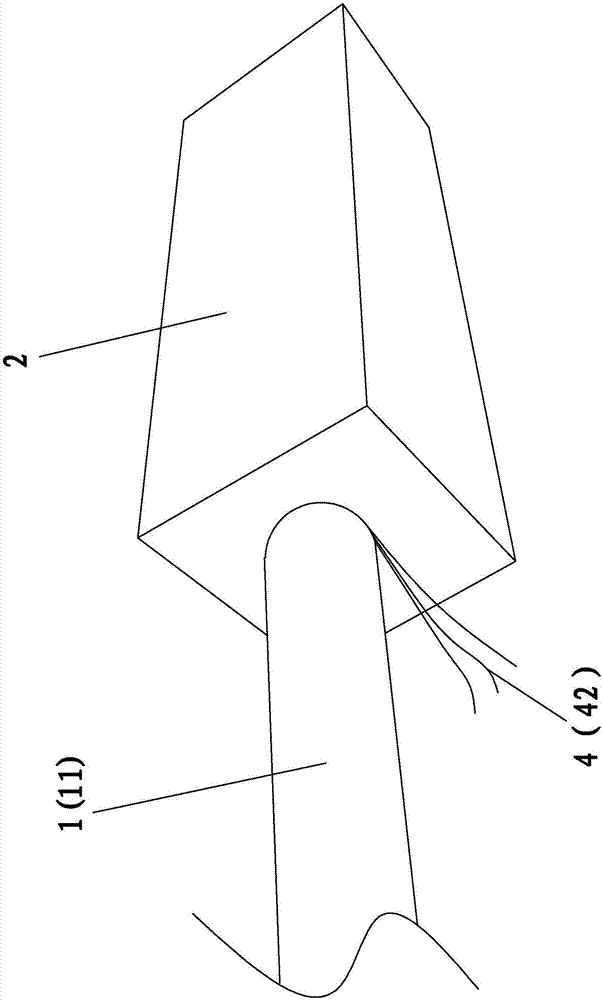

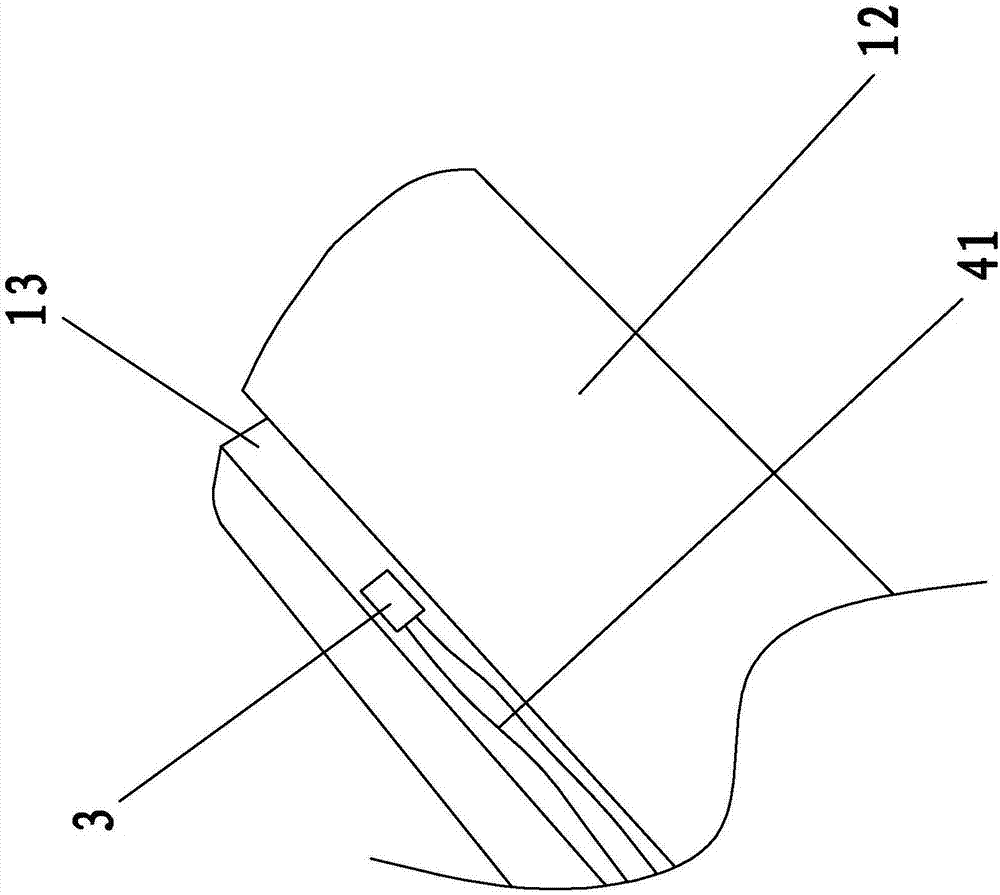

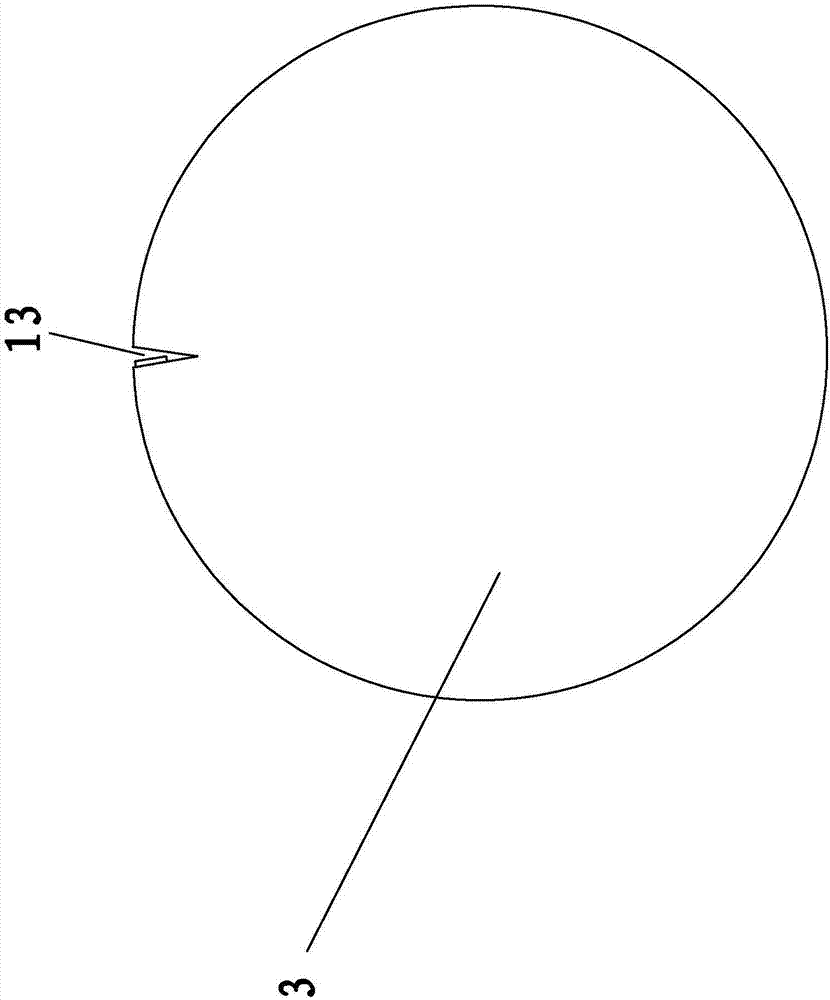

[0033] A rammed earth-wood beam-column specimen, such as Figure 1-3 As shown, it includes wooden beam column 1 and rammed earth part 2. The wooden beam column 1 includes a free section 11 and a rammed earth section 12 . The soil body is rammed on the rammed earth section 12 to form the rammed earth part 2 . In common rammed earth-wooden beam-column specimens, the wooden beam-column 1 is cylindrical, and the rammed-earth part 2 is square column-shaped. The wooden beam column 1 can be provided with a plurality of rammed earth sections 12 arranged at intervals. Preferably, the end of the wooden beam column 1 is a rammed earth segment 12 . The rammed earth sections 12 of the plurality of sections correspond to rammed earth bodies respectively. In order to measure the strain parameters of the rammed structure,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap