Programmable-control four-channel valve device and using method thereof

A programming control and valve device technology, which is applied to valve devices, valve operation/release devices, multi-way valves, etc., can solve problems such as inability to adjust the opening, the utilization rate of external leakage actuators, and internal leakage of electric valves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

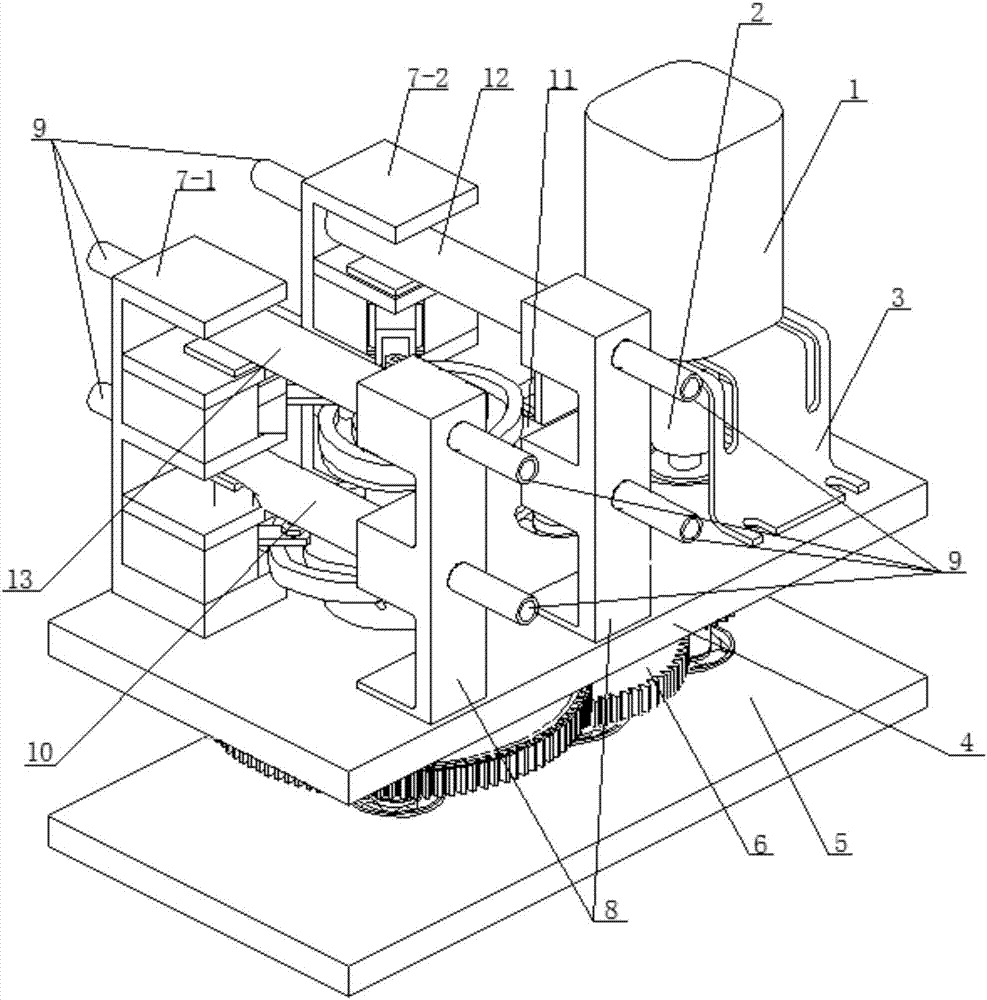

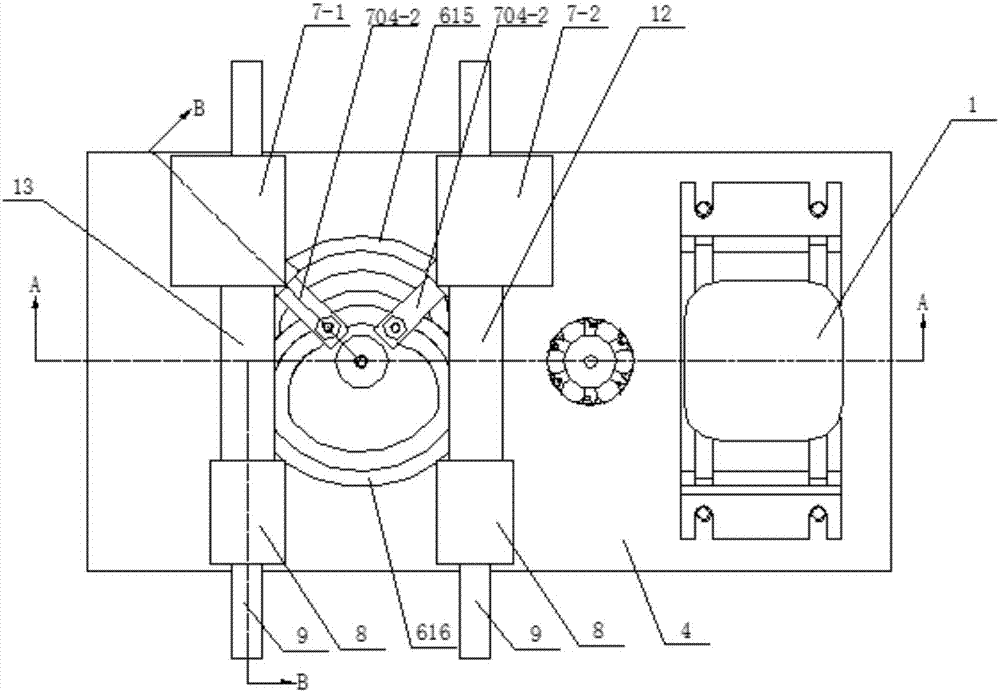

[0045] Specific implementation mode 1: Combination Figure 1-5 Detailed description of this embodiment, this embodiment is a programmable control four-channel valve device consisting of a stepping motor 1, an elastic coupling 2, a motor bracket 3, a mounting seat 4, a base 5, a cam mechanism 6, a first slave Driving mechanism 7-1, second driven mechanism 7-2, 2 hose holders 8, 8 hose joints 9, first channel hose 10, second channel hose 11, third channel hose 12 , The fourth channel hose 13 and PLC controller composition;

[0046] The motor support 3 is fixed on the upper surface of the mounting base 4, the stepping motor 1 is arranged on the upper surface of the motor support 3, and the motor shaft of the stepping motor 1 penetrates the motor support 3 downwards and is fixed to the upper end of the elastic coupling 2;

[0047] A base 5 is provided under the mounting base 4, and a cam mechanism 6 is provided between the mounting base 4 and the base 5;

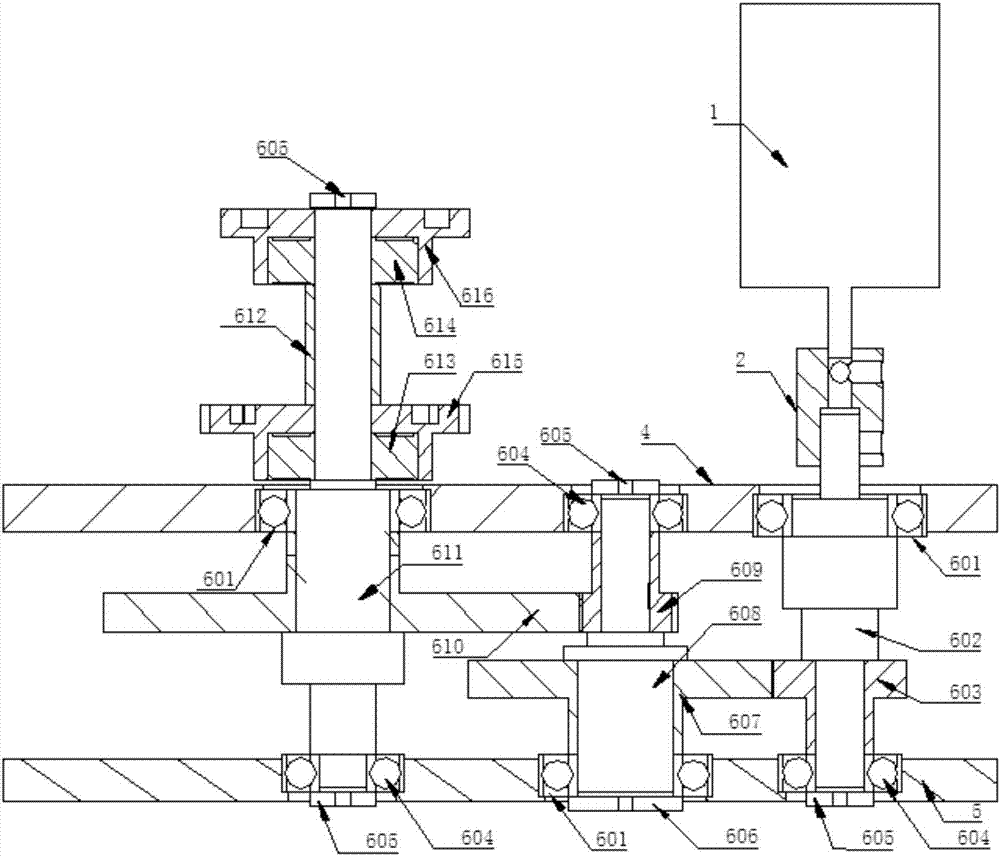

[0048] The cam mechanism 6 is...

specific Embodiment approach 2

[0085] Second embodiment: The difference between this embodiment and the first embodiment is that the width of the cam grooves of the first cam 615 and the second cam 616 is 1 to 1.1 times the diameter of the outer ring of the cam guide 705 bearing. Others are the same as the first embodiment.

specific Embodiment approach 3

[0086] Specific embodiment three: The difference between this embodiment and specific embodiments one or two is: the elastic coupling 2 is a parallel linear elastic coupling. Others are the same as the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com