Outer drum cover of washing machine, washing machine and control method

A technology for outer barrel lids and washing machines, applied in the field of washing machines, which can solve the problems of not considering the direction of water flow, poor diversion effect, unfavorable water flow, etc., and achieve good spraying effect, good diversion effect, and good spraying effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

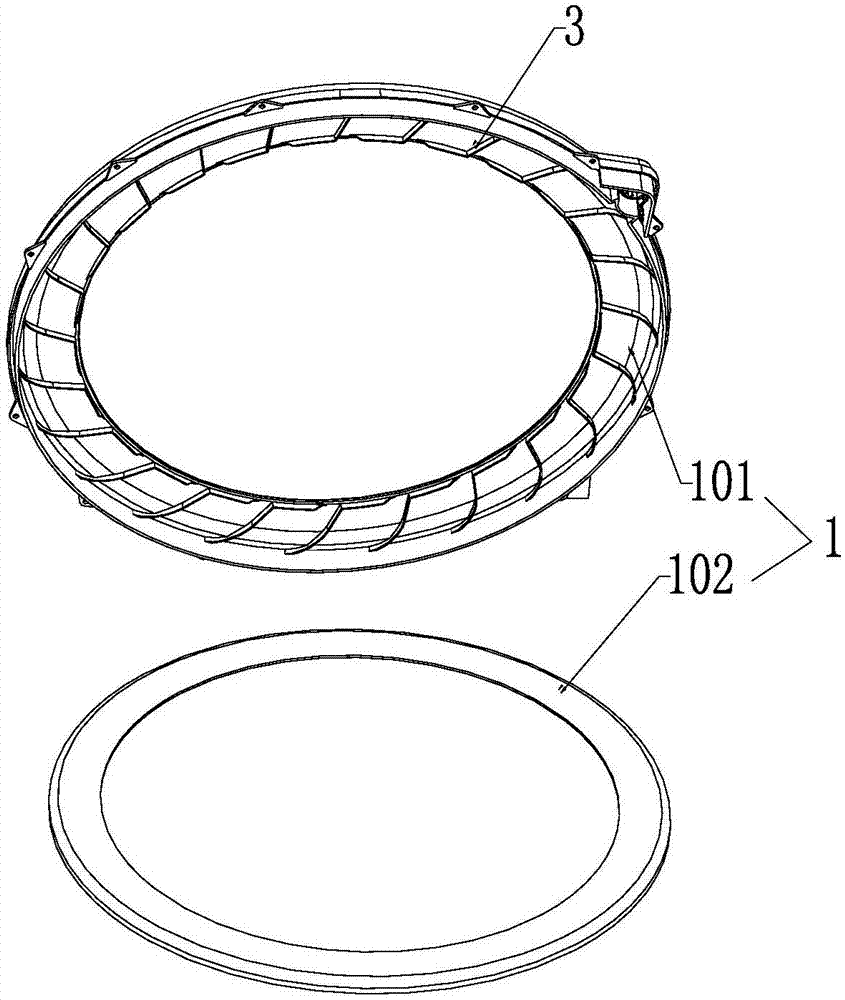

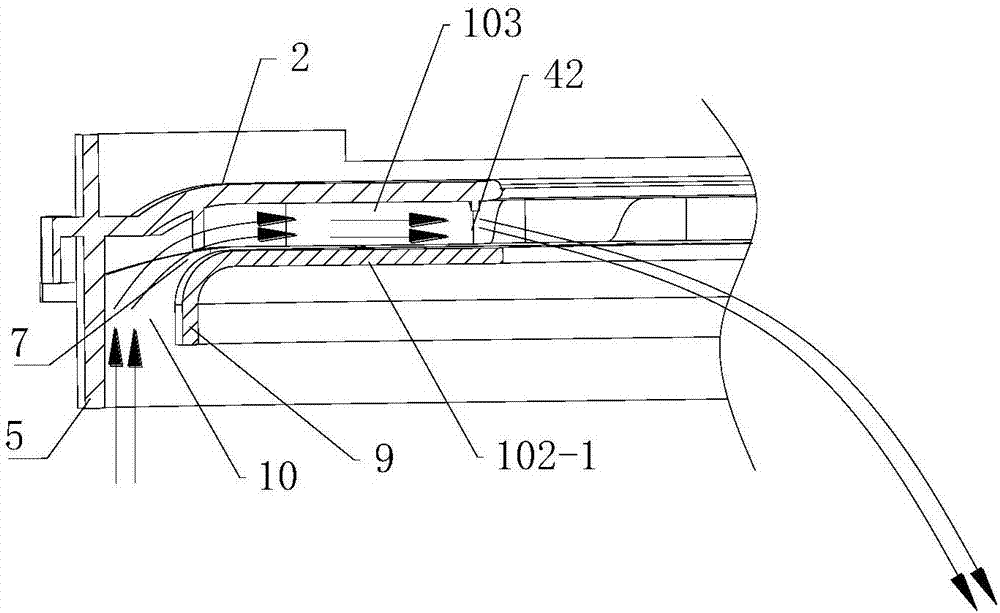

[0050] Such as Figure 1-10 As shown, the present embodiment provides an outer barrel cover 1 of a washing machine. The outer barrel cover 1 has an annular cavity 103, and the outer periphery of the annular cavity 103 is provided with a water inlet 7, and the water inlet 7 is located on the outer barrel of the outer barrel. Inside, after the water flow is lifted along the inner wall of the outer barrel, it enters the annular chamber 103 through the water inlet 7, and sprays into the inner barrel.

[0051] The outer tub cover 1 of this embodiment has an annular cavity 103, and the water inlet 7 of the annular cavity 103 is on the outer periphery and inside the outer tub of the washing machine. After the outer bucket cover is installed on the upper part of the outer bucket, the inner side extends to contact the balance ring, so the annular cavity 103 can isolate the water flow from the rotating inner bucket and the balance ring. In this way, under the rotation of the inner tub ...

Embodiment 2

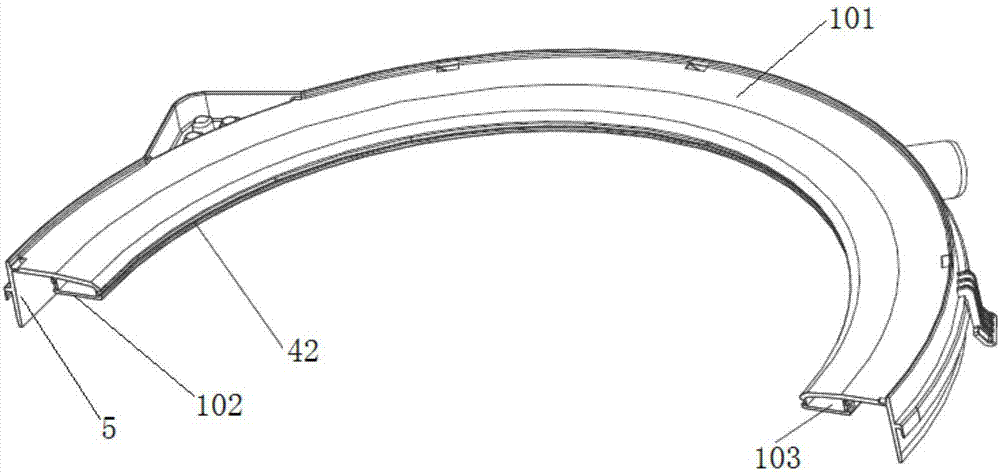

[0071] Such as Figure 6-Figure 13 As shown, this embodiment is a further limitation of the embodiment. A washing machine outer barrel cover 1 is provided, and a flow guide structure is also provided in the annular cavity, and the flow guide structure extends from the outer peripheral side of the annular cavity to the inner peripheral side. The diversion channels 4 with narrowed water outlets are respectively formed between the adjacent diversion structures 3, and the water flow enters the diversion channels 4 after being lifted and is sprayed from the water outlets to the inner tub.

[0072] The upper cover body of the outer barrel cover 1 of the washing machine is ring-shaped, and the outer periphery of the outer barrel cover 1 is sealed and connected with the outer barrel. When washing, the motor drives the pulsator and the inner barrel to rotate, and then drives the water flow to rotate. Under the action of centrifugal force generated by high-speed rotation, the water flow ...

Embodiment 3

[0090] Such as Figure 6 to Figure 8 As shown, the present embodiment is a further limitation of the second embodiment. The extended guide rib 32 of the present embodiment includes a straight guide section 32-1 and an arc guide section 32-2, and one end of the straight guide section 32-1 It is connected with the end of the circumferential guide rib 31, and the other end is connected with the arc-shaped guide section 32-2. connect.

[0091] The straight guide section 32 - 1 and the arc guide section 32 - 2 extending the guide rib 32 can be integrally formed or seamlessly connected. The arc-shaped diversion section 32-2 bends and extends from the outer peripheral flanging 5 to the inner periphery, and when the water flow rotates and climbs under the rotation of the inner barrel, it can enter the diversion channel 4 along the curved arc-shaped diversion section 32-2, The diversion effect is good. The straight-line diversion section 32-1 connects the arc-shaped diversion sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com