Robot sausage placing machine for multiple sausages

A robot and robot body technology, applied in packaging and other directions, can solve the problems of mechanical swinging of multiple intestines, achieve the effect of eliminating food hygiene safety hazards and increasing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

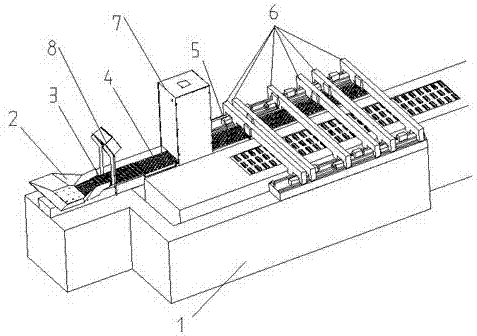

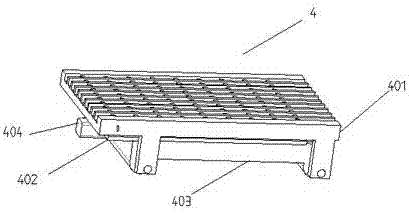

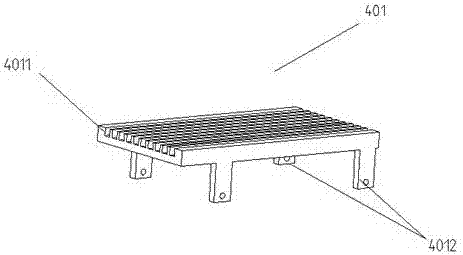

[0024] Such as figure 1 As shown, a robotic sausage swinging machine for multiple sausages includes a frame 1, on which a vibrating feeder 2 for storing and conveying, and a whole column that can destroy the stacked state of sausages and arrange them in columns The feeder 3 and the stepping feeder 4 capable of pulling the distance between the front and rear of the sausage, the feeding conveyor 5 for transporting the sausage, the robot 6 capable of moving the sausage on the feeding conveyor 5, the vibrating feeder 2, and the alignment feeder 3 , the stepping feeder 4 and the feeding conveyor 5 are connected in sequence, and the robot 6 is arranged on the upper side of the feeding conveyor 5; the sausage is sent into the vibrating feeder 2 by an external conveyor, and is vibrated by the vibrating feeder 2 to the whole column feeding The stacker 3 sorts out the stacking state...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com