A kelp farming and harvesting integrated machine

An all-in-one machine and kelp technology, which is applied to harvesters, seaweed cultivation, agricultural machinery and tools, etc., can solve the problems of time-consuming, labor-intensive, low work efficiency, etc., and achieve the effect of convenient use, reasonable structure, and labor liberation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

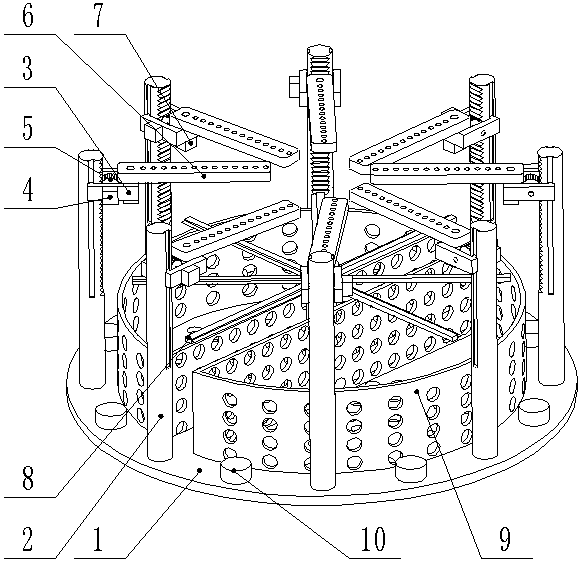

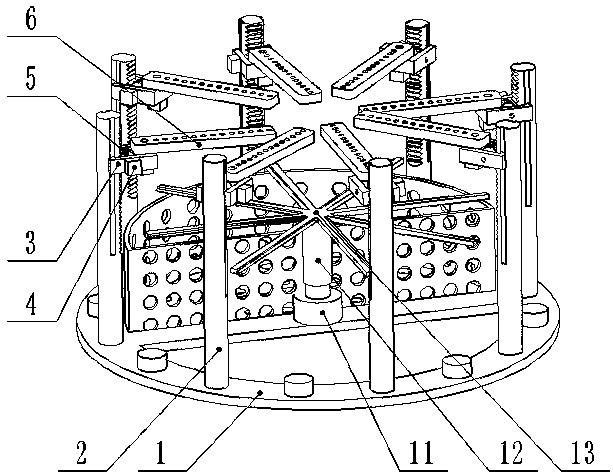

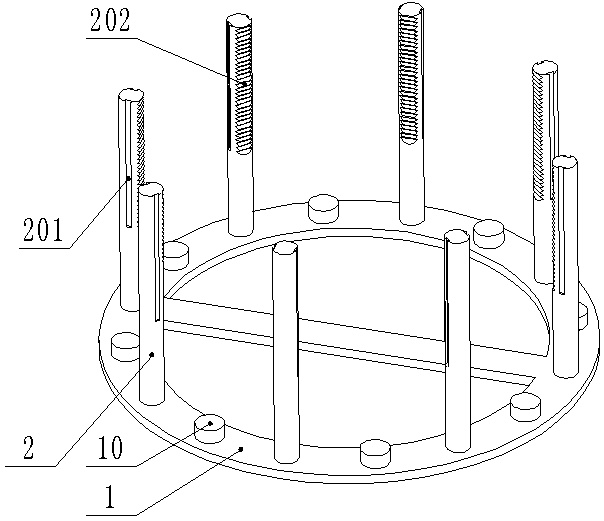

[0015] Such as Figure 1 to Figure 4 As shown, a kelp cultivation and harvesting integrated machine includes a chassis 1, eight vertical poles 2, eight lifting motors 4 and eight lifting gears 5, eight lifting frames 3, eight cultivation rods 6 and eight cultivation adjustment motors 7. Two collection frames 9, harvesting adjustment frame 13, lifting electric cylinder 12 and rotating motor 11, characterized in that: eight vertical rods 2 are evenly distributed and vertically arranged on the circumference of the chassis 1, and each vertical rod 2 is arranged along the axial direction There are two chutes 201 symmetrically arranged, and a toothed structure 202 arranged in the axial direction is arranged between the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com