Ultra-deep hole pre-splitting blasting method

A pre-split blasting and ultra-deep hole technology is applied in the field of pre-split blasting of open-pit stope slopes to achieve the effects of reducing production costs, reducing maintenance costs and improving crushing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

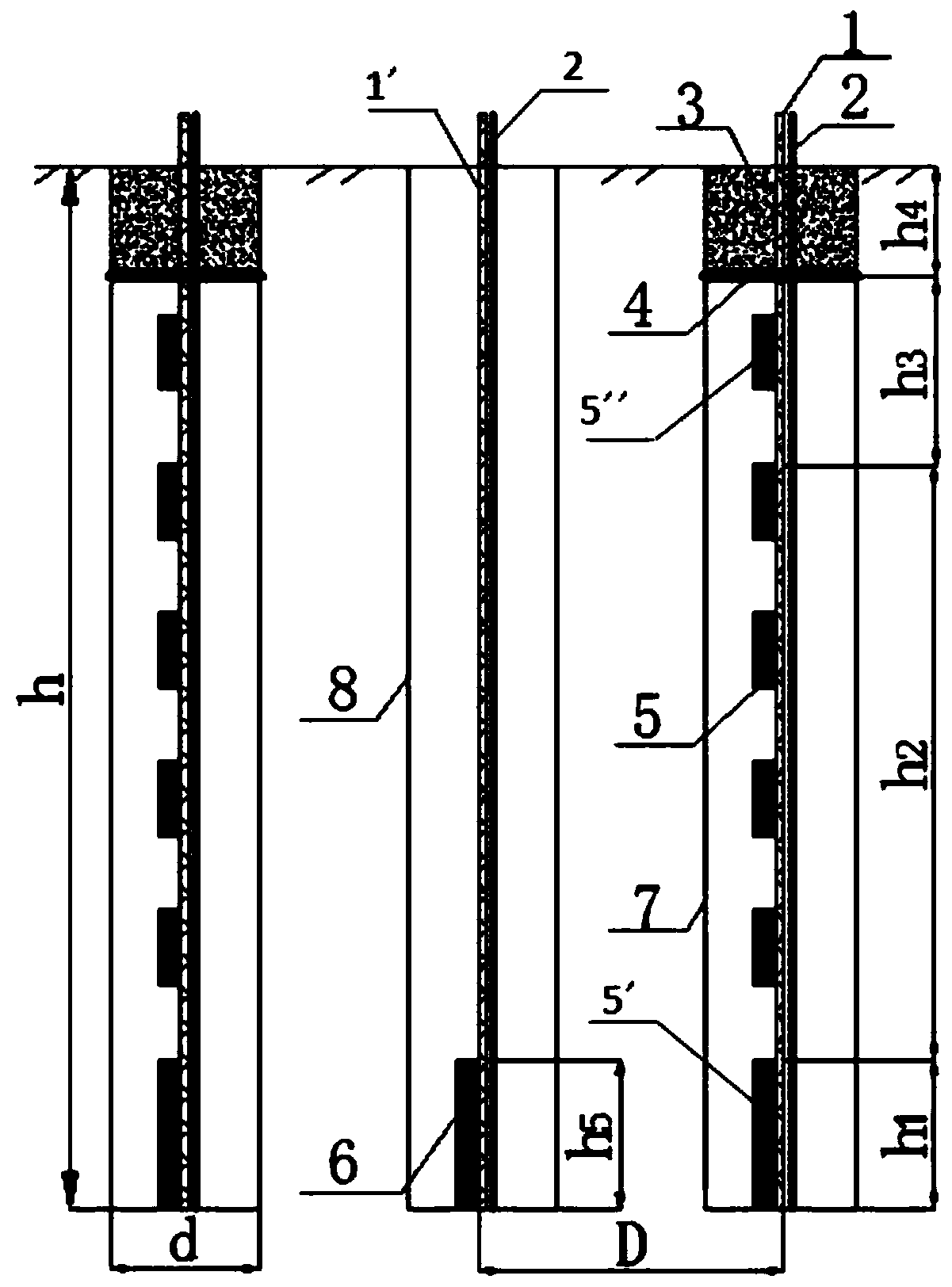

[0024] In order to better describe the present invention, the method for ultra-deep hole pre-splitting blasting of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0025] Depend on figure 1 The schematic diagram of the charge structure of the method for the ultra-deep hole pre-splitting blasting of the present invention as shown shows that the method for the ultra-deep hole pre-splitting blasting of the present invention divides the blast hole into a pre-splitting blast hole 7 and a guide blast hole 8, and the borehole diameter d , The blast hole depth is h, and the hole spacing is D; the guide blast hole 8 is charged and blocked only at a certain height at the bottom, and the upper part is air. The pre-splitting blast hole 7 is the reinforced charge section h from bottom to top 1 , normal charging section h 2 , Weaken charge section h 3 and packing section h 4 .

[0026] where: h=h 1 + h 2 + h 3 + h 4 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com