Novel rod feeding mechanical arm of aluminum profile extrusion machine

A technology for extruders and aluminum profiles, which is applied in the field of manipulator structure for feeding rods of aluminum profiles, can solve the problems of the manipulator’s material removal obstruction, poor moving accuracy, and uneven feeding of material rods, so as to avoid hindering material removal and achieve stable performance. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings.

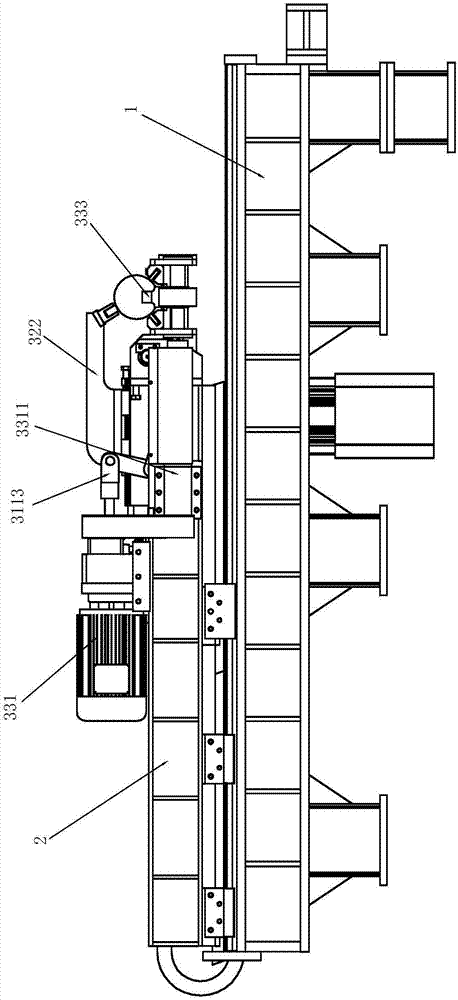

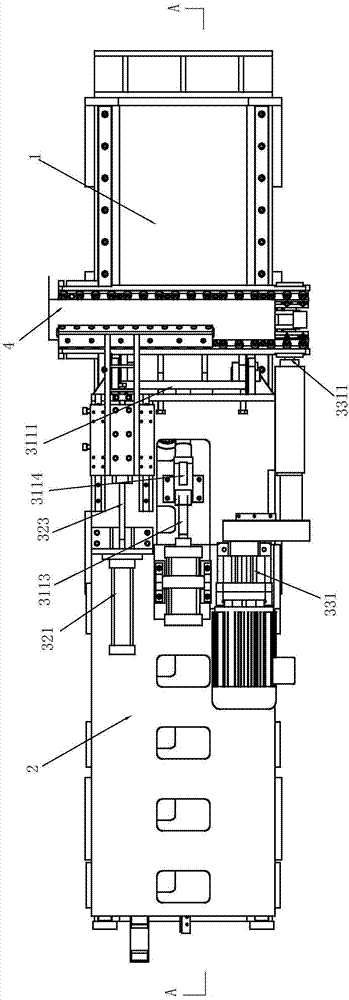

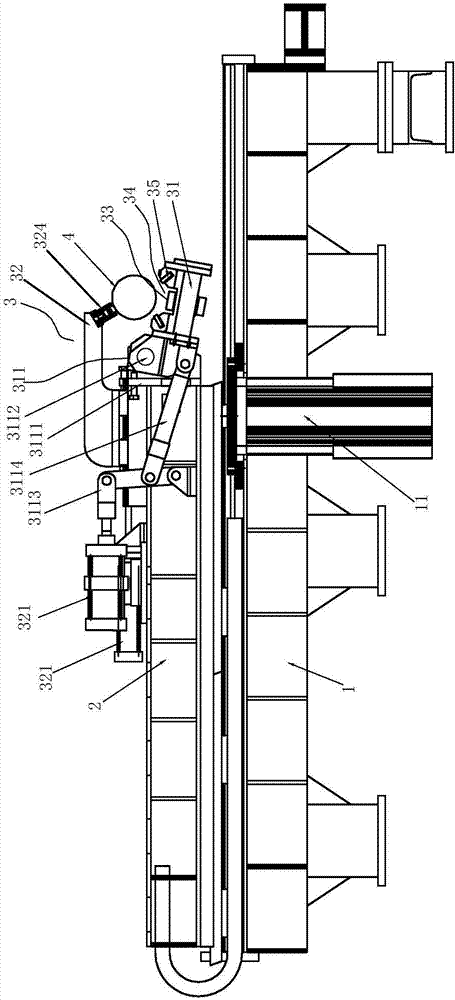

[0022] refer to Figure 1 to Figure 4 The new-type rod-feeding manipulator of the aluminum extrusion machine shown includes a lower frame 1 and an upper frame 2. The upper frame 2 is slidably installed on the lower frame 1, and a pusher is installed on the upper frame 2. Mechanism 3, the described upper frame 1 directly drives the gear and the rack to move back and forth on the lower frame 2 through a moving motor, and the described upper frame 2 moves forward and backward on the lower frame 1 driven by a moving motor 11; The pushing mechanism 3 includes a support rod frame 31, a pressing rod device 32 and a material pushing device 33, the described supporting rod frame 31 is used to place the material rod 4, and the pressing rod device 32 is used to compress the material rod on the support On the rod holder 31, the pusher device 32 is used to push the mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com