Remotely controlled aerial working glass wiping robot

A high-altitude operation and glass-cleaning technology, which is applied in the field of intelligent robots, can solve problems such as high labor intensity, time-consuming and labor-intensive efficiency, and safety accidents, and achieve the effects of easy portability and operation, avoiding casualties, and good cleaning effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

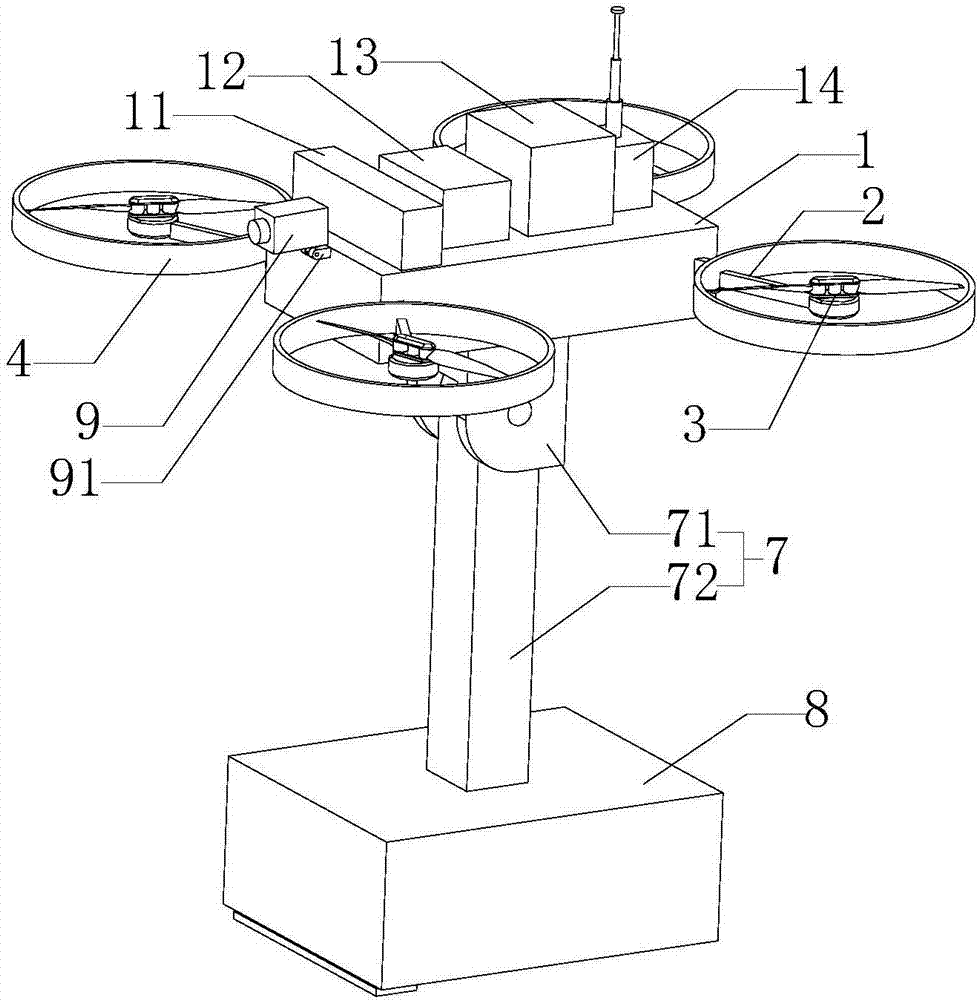

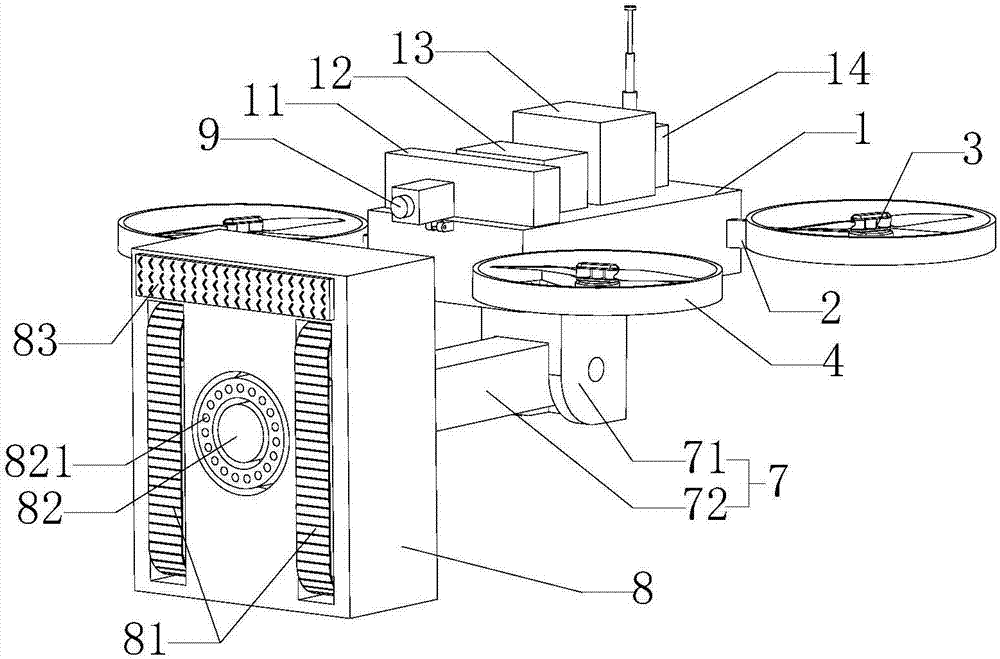

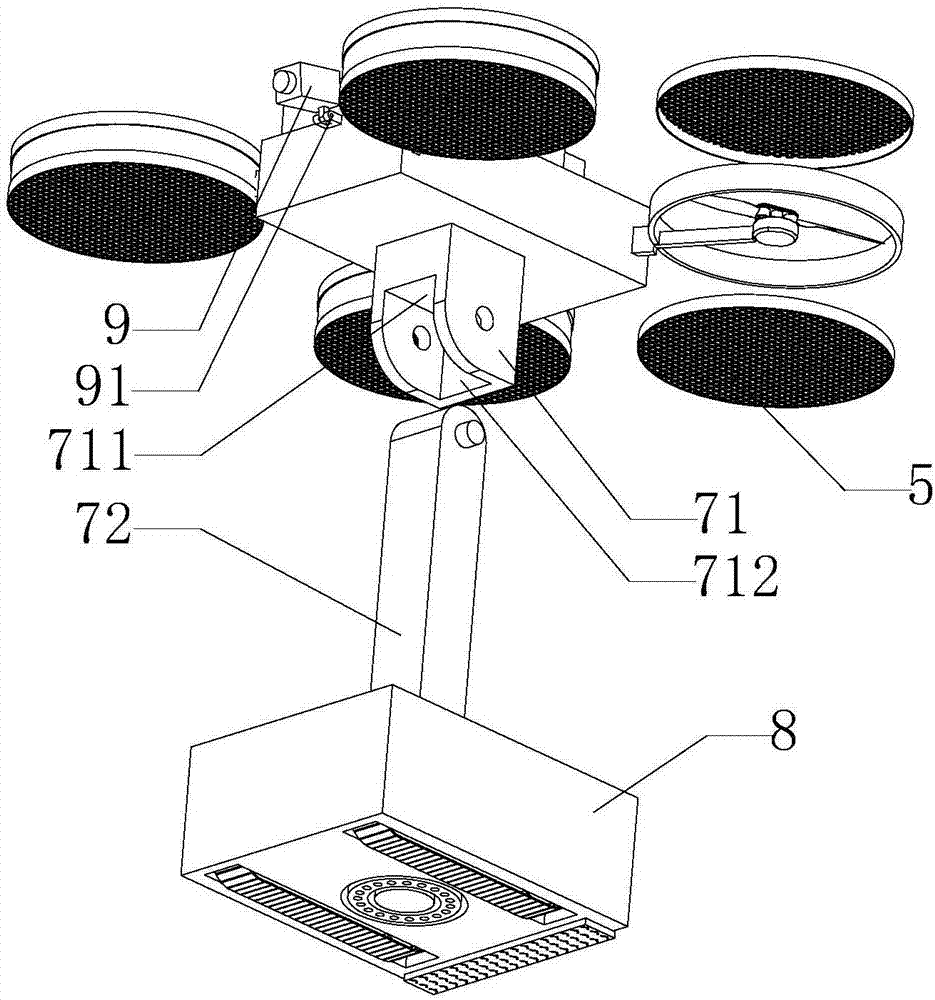

[0033] The present invention will be further described below in conjunction with accompanying drawing:

[0034] Such as figure 1 , 2 As shown, a robot for remote-controlled high-altitude cleaning glass includes a fuselage 1, four arms 2 are evenly distributed around the fuselage 1, and the other end of each arm 2 is equipped with an electric propeller 3, and also includes The remote controller 6; the bottom of the fuselage 1 is connected with a rotating mechanism 7, and the rotating mechanism 7 includes a rotation limiting seat 71 fixed on the bottom of the fuselage 1 and a rotating connecting rod 72 hinged with the rotating limiting seat 71, and is connected in rotation The other end of the rod 72 is fixedly connected with a glass cleaning device 8; a camera 9, a battery module 11, a flight control module 12, a cleaning control module 13 and a data transmission module 14 are arranged on the top of the fuselage 1; The propeller 3, the rotating mechanism 6, the camera 9, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com