A centrifugal production process for separating gypsum

A production process, centrifugal technology, applied in the direction of inorganic chemistry, chemical instruments and methods, calcium/strontium/barium sulfate, etc., can solve the problems of reduced market competitiveness, unspecific process parameters, high biochemical indicators, etc., and achieve saving treatment The effect of saving time, improving processing efficiency, and maximizing operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

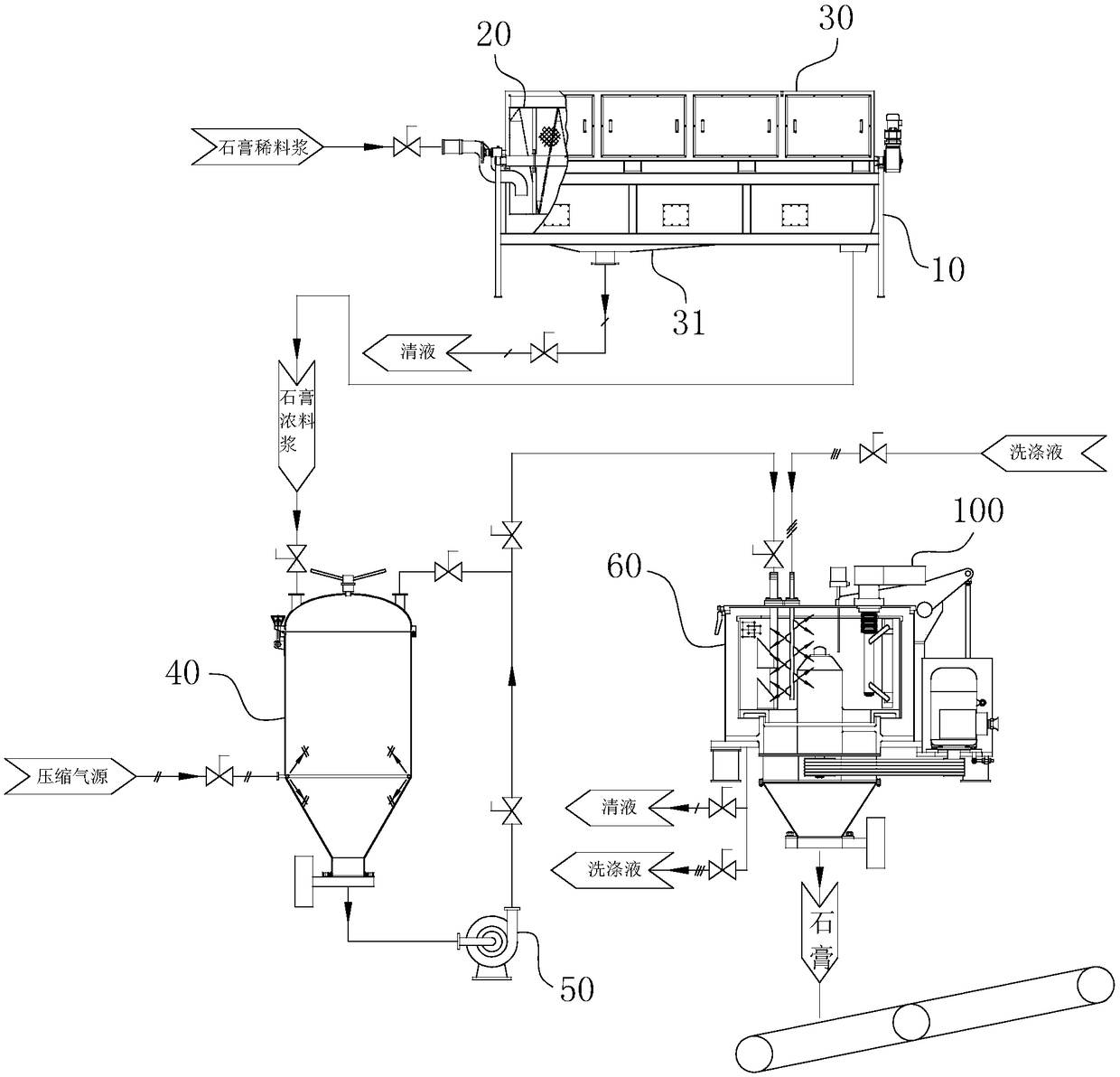

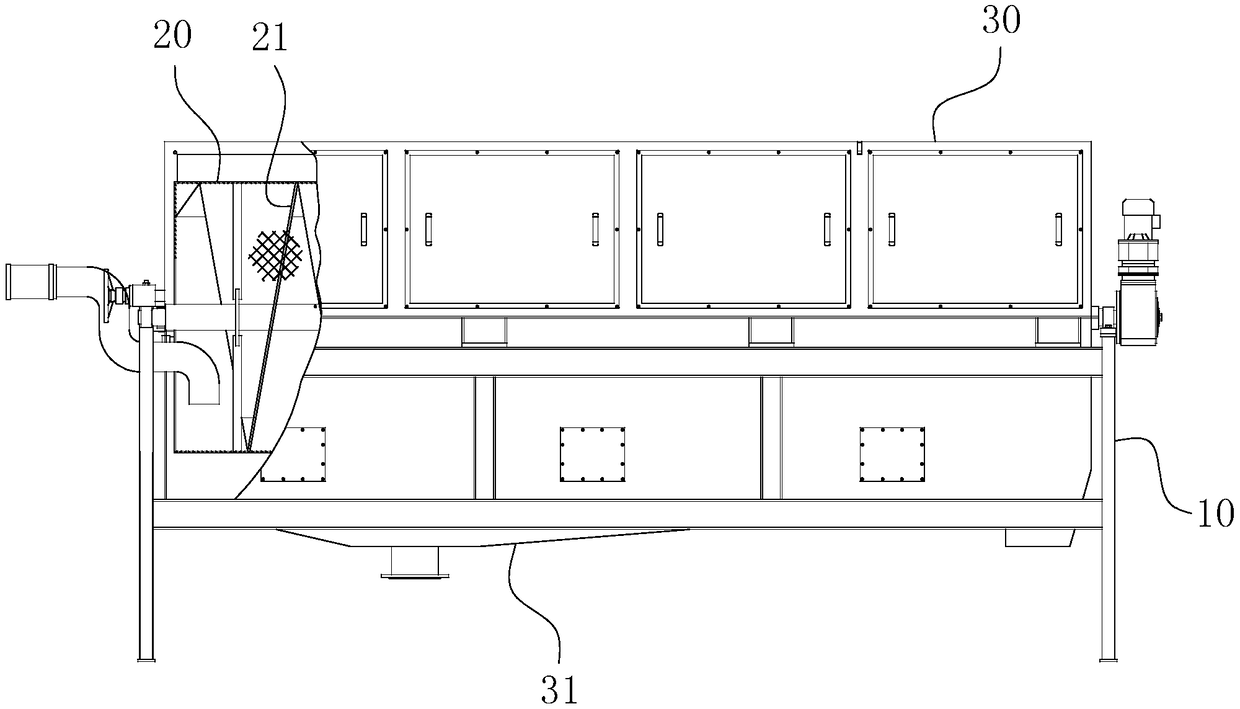

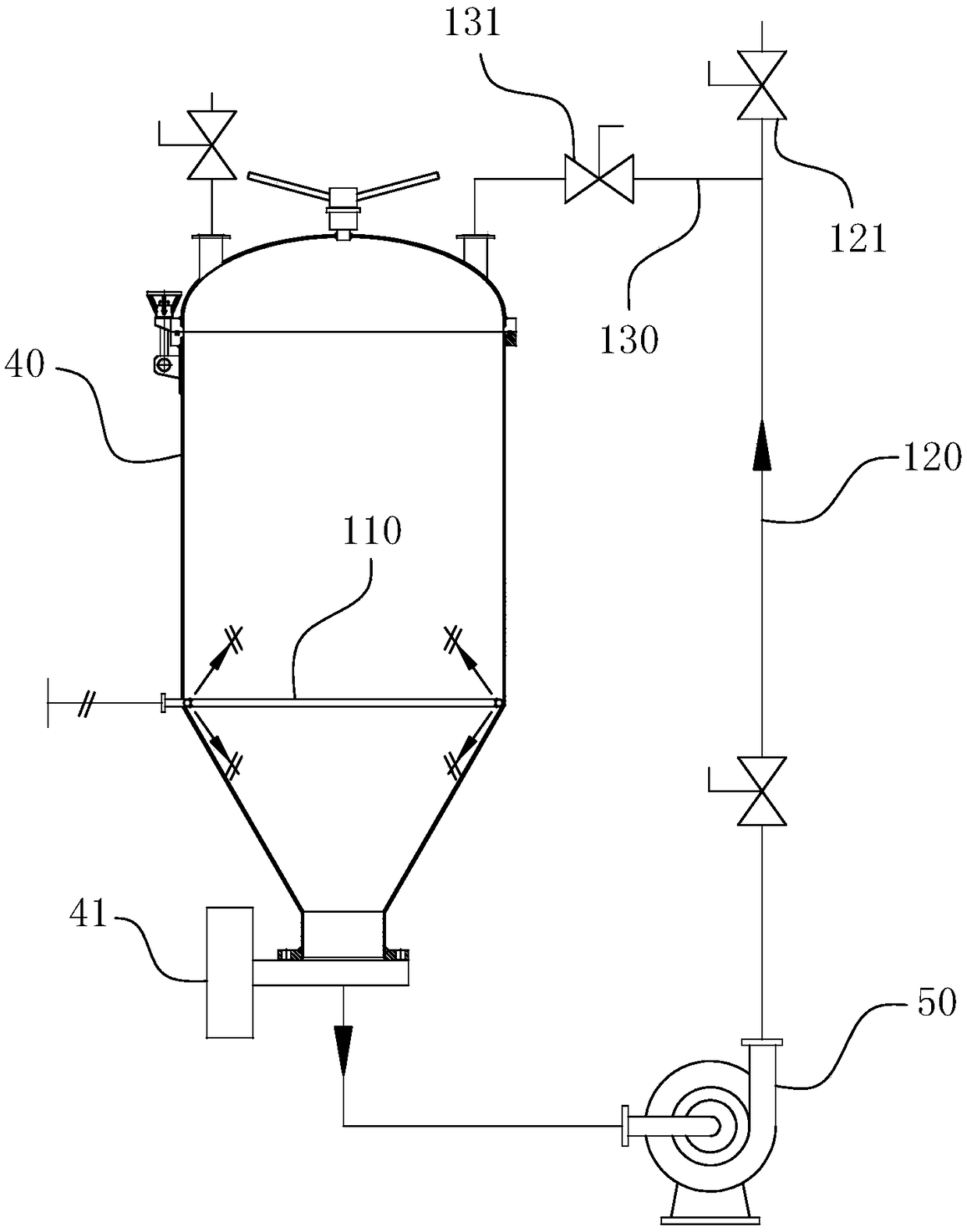

[0050] Concrete working structure of the present invention, as Figure 1-12 As shown, it includes a slurry thickening device for preliminary dehydration, a slurry homogenization device for mixing the slurry, and a centrifugal dehydration device for dehydrating and washing the slurry and scraping the filter cake. , in order to realize the step of thickening the slurry for adjusting the solid mass fraction of the thin gypsum slurry to 20% to 30%, the step of homogenizing the slurry for mixing the slurry, and the step of dehydrating and washing the slurry. The centrifugation step of the filter cake scraping process. For ease of understanding, the specific workflow of the present invention is described as follows here:

[0051] The original design intention of the present invention is: due to the flue gas in the flue of smeltery, thermal power plant, etc., the sulfuric acid produced by the flue gas acid system is added with lime to generate a gypsum solution. This is a convention...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com