Stirrer

A technology of agitator and agitator, applied in the directions of agitator accessories, chemical instruments and methods, dissolution, etc., can solve the problem that the material and liquid cannot achieve a good circulation stirring effect, affect the product quality and use effect, and increase the reaction time and side reactions. and other problems, to achieve the effect of reasonable overall structure setting, good stirring effect, and improved effect and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

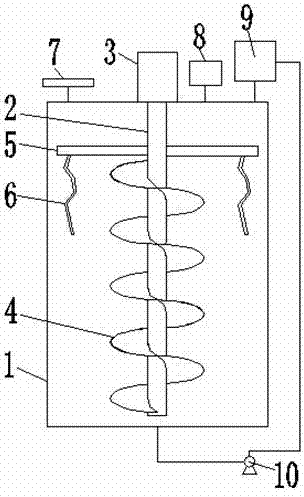

[0013] like figure 1 As shown, a kind of stirrer of the present invention, it comprises housing 1, is provided with stirring main shaft 2 in the middle part of described housing 1, is provided with motor 3 on described stirring main shaft 2 upper end, and described stirring main shaft 2 A spirally rising internal spiral belt 4 is provided on the top, a support rod 5 is provided on the stirring main shaft 2 above the internal spiral belt 4, and a self-rotating stirring member 6 is arranged on the support rod 5. On the side of the motor 3 The top of the housing 1 is provided with an automatic batcher 7, a monitoring device 8 is provided on the other side of the motor 3, and a mixing tank 9 is provided next to the monitoring device 8, and the mixing tank 9 passes through the pipeline and the housing 1 is connected to the bottom, a material pump 10 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com