Material mixing device for chemical production

A mixing device and chemical production technology, which is applied in the field of mixing devices for chemical production, can solve the problems of inability to ensure the working stability of the mixing device, poor mixing effect, and no shock absorption function, etc., so as to improve the mixing effect and work efficiency, stirring fully and evenly, and improving the effect of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

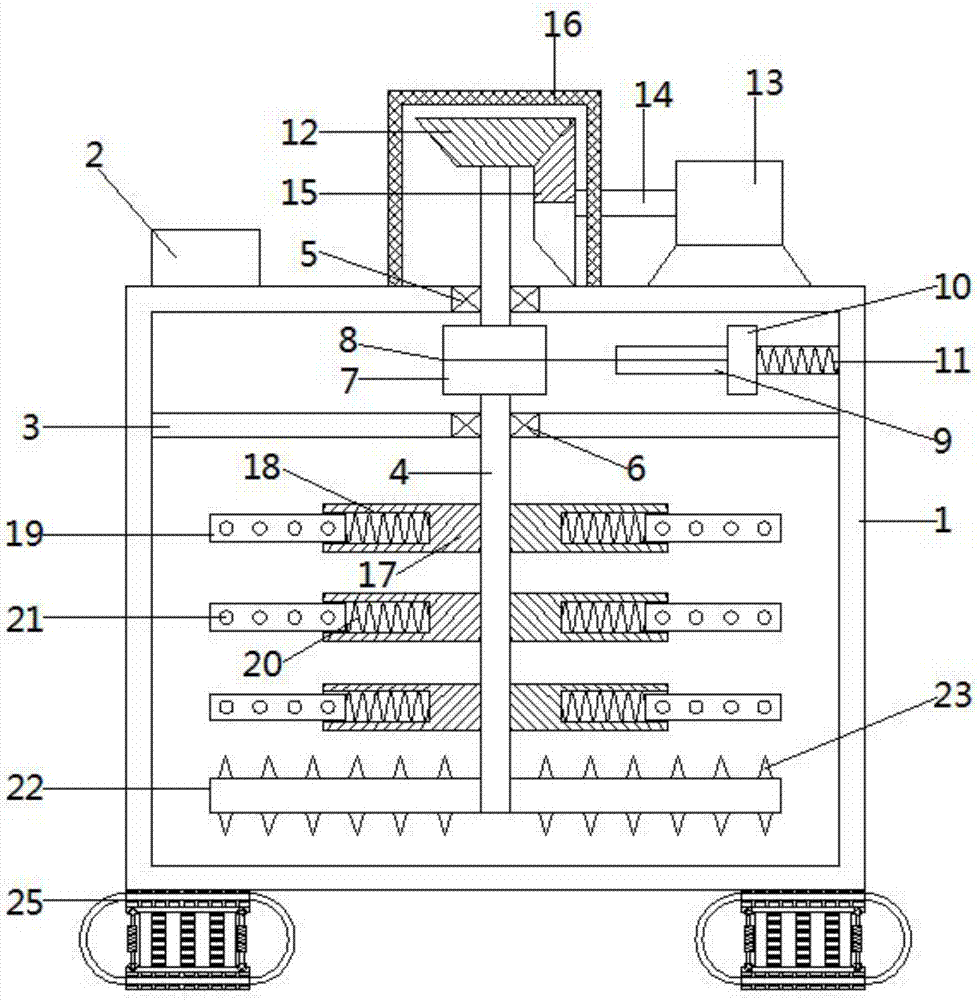

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

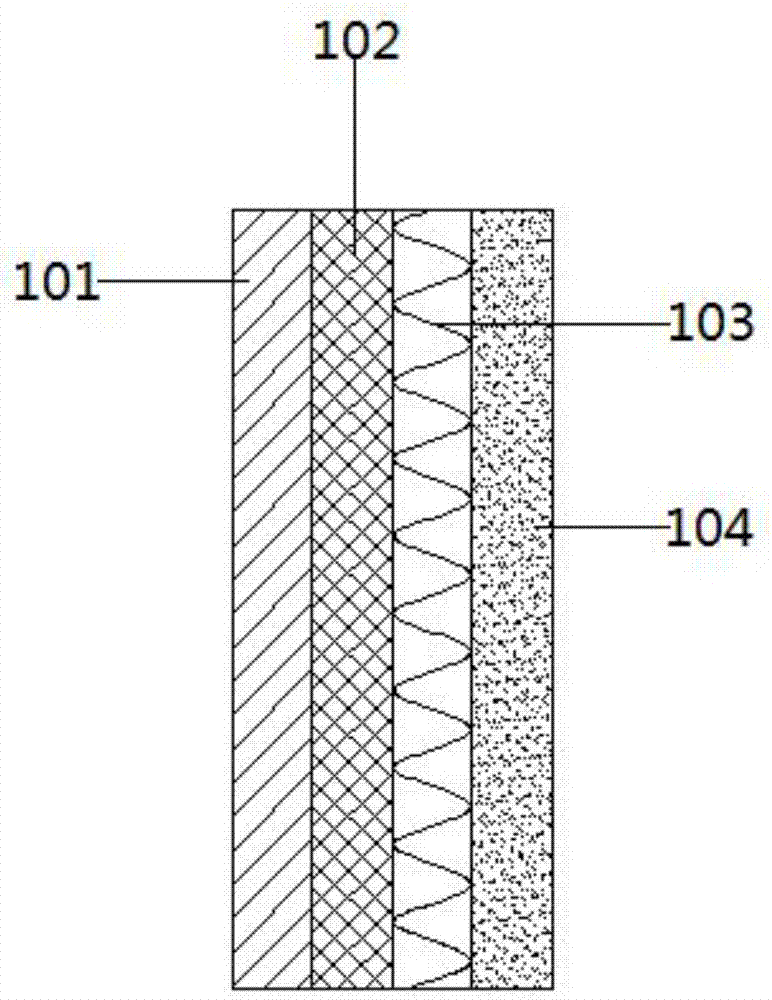

[0021] see Figure 1-2 , in an embodiment of the present invention, a mixing device for chemical production includes a body 1, the body 1 includes a body 101, the inside of the body 101 is provided with an insulation layer 102, the insulation layer 102 is a polyurethane insulation layer, and the insulation layer 102 A resistance wire heating layer 103 is provided on the inner side, a ceramic layer 104 is provided on the inner side of the electric heating layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com