Bean crop threshing device

A threshing device and technology for crops, which are applied in threshing equipment, agriculture, agricultural machinery and implements, etc., can solve the problems that bean crop threshing cannot be realized and cannot meet the production needs of users, and can improve the threshing rate and threshing efficiency. The effect of space and smooth threshing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

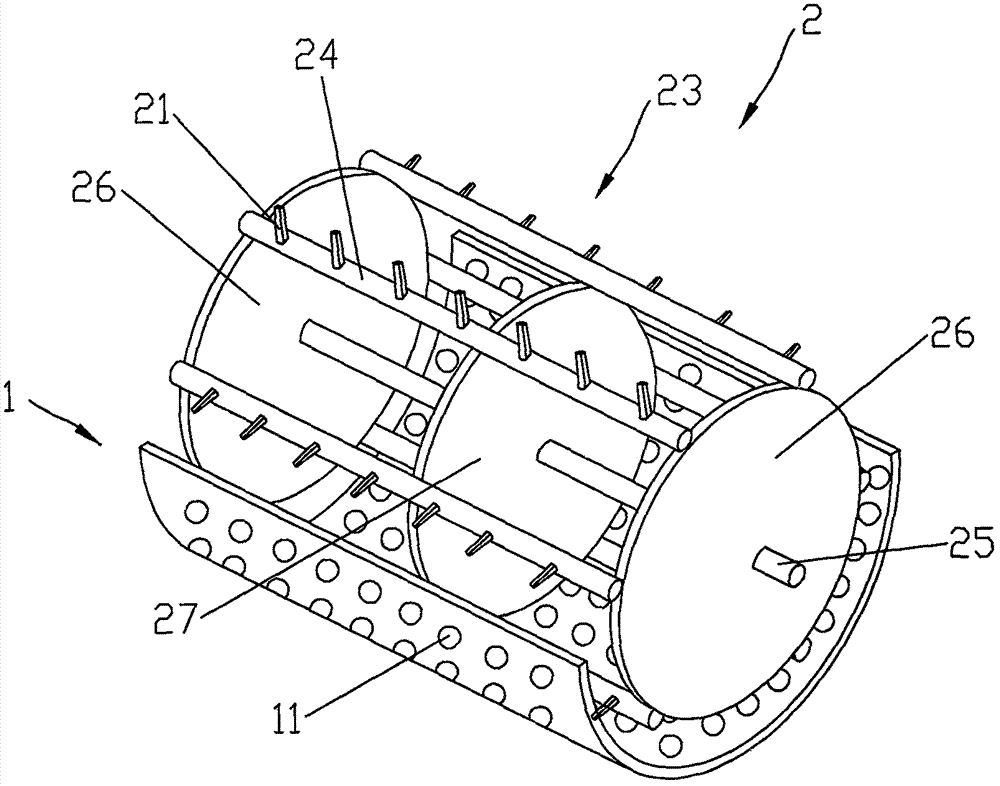

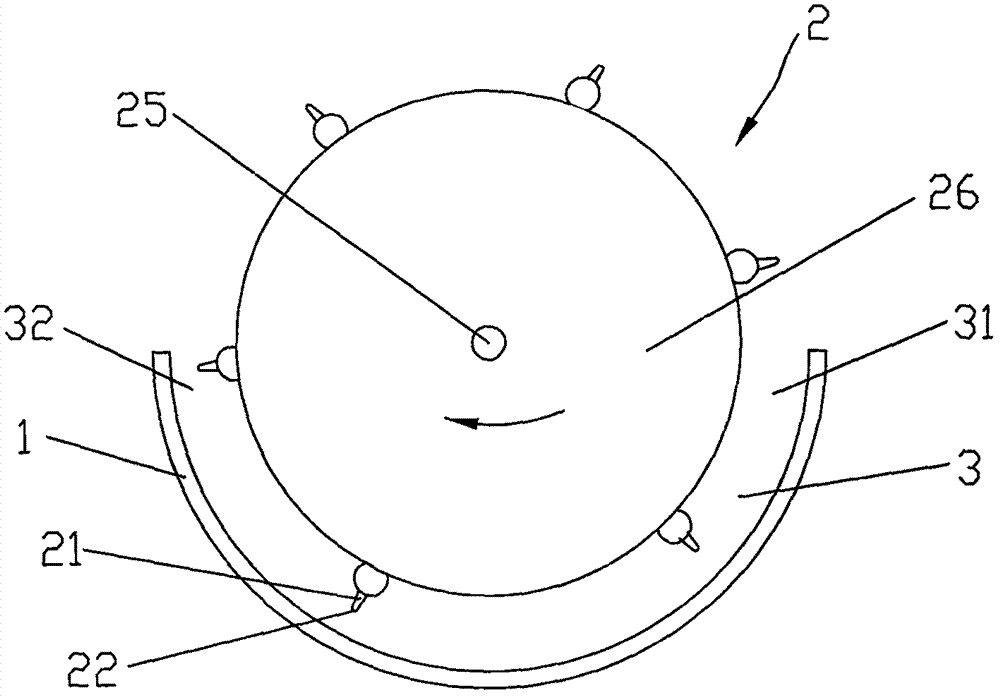

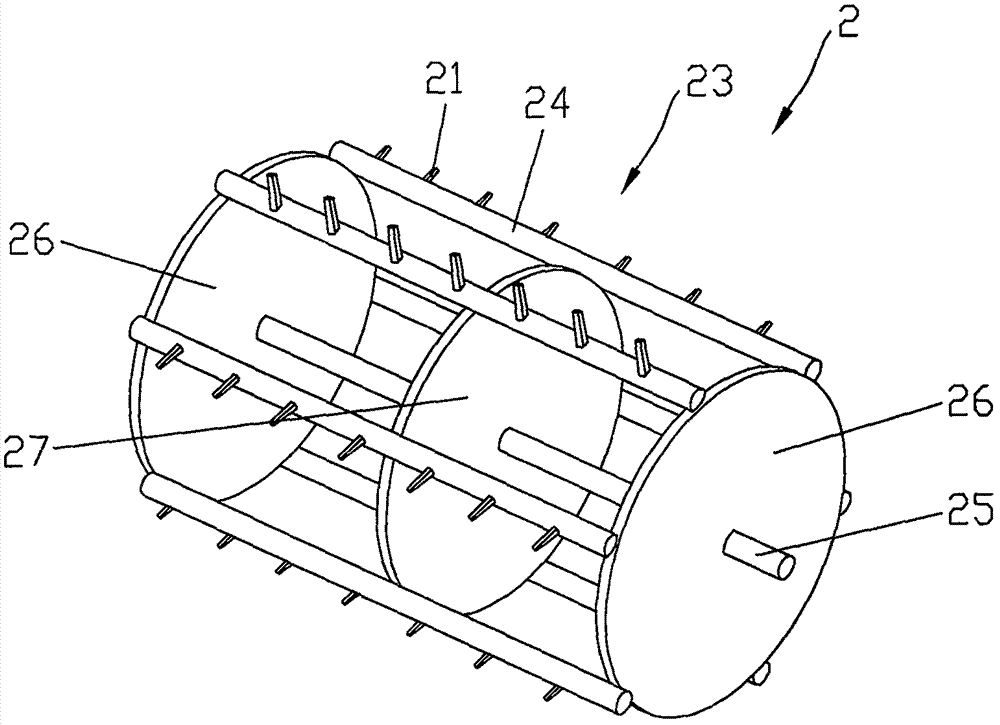

[0016] refer to figure 1 with figure 2 , a bean crop threshing device, comprising a threshing filter screen 1 and a threshing drum 2 that can rotate relative to the threshing filter screen 1, the threshing drum 2 is provided with a number of threshing teeth 21, and the threshing filter screen 1 is placed on the The periphery of the threshing cylinder 2 wraps the threshing cylinder 2, and there is a gap between the threshing filter screen 1 and the threshing cylinder 2 to form a threshing chamber 3, and the threshing chamber 3 is located between the two ends of the threshing cylinder 2. The sides are respectively the material inlet 31 and the material outlet 32, the distance between the end 22 of the threshing gear 21 and the threshing filter screen 1 is higher than the height of the beans, and the threshing filter screen 1 is provided with a The strainer holes 11 through which the beans pass.

[0017] Through the setting of the above-mentioned structure in the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com