Robot chassis capable of achieving omnidirectional movement and independent line patrol

A robot and chassis technology, applied in the direction of motion deposition, motor vehicles, power devices, etc., can solve the problems of poor versatility and mobility, and achieve the effects of good adaptability, strong mobility, and multi-functional use range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

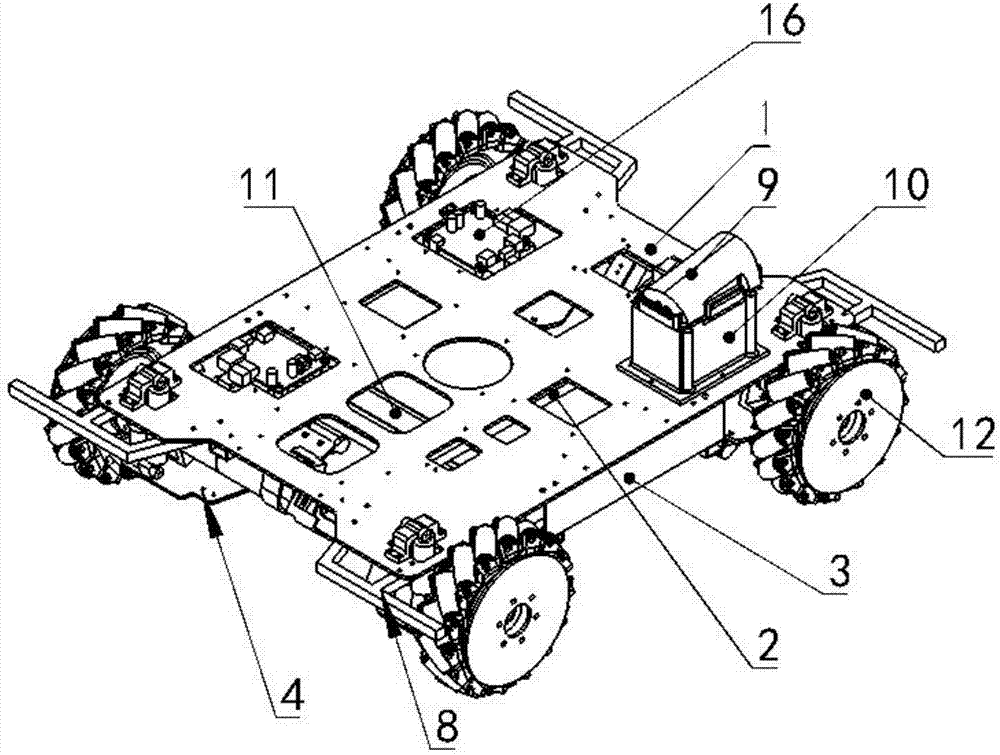

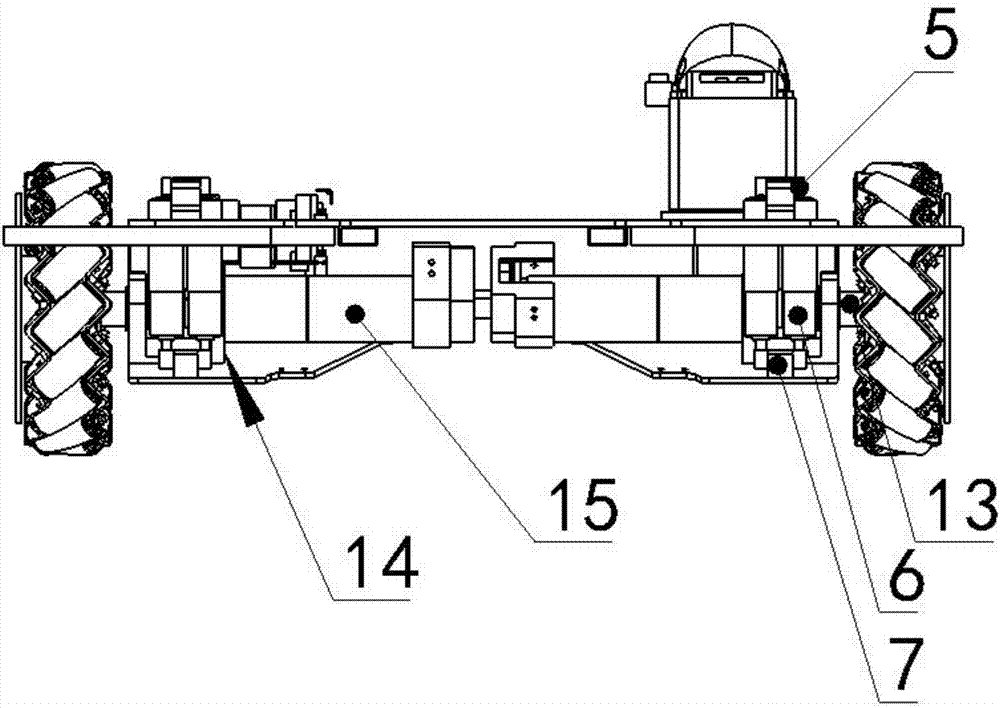

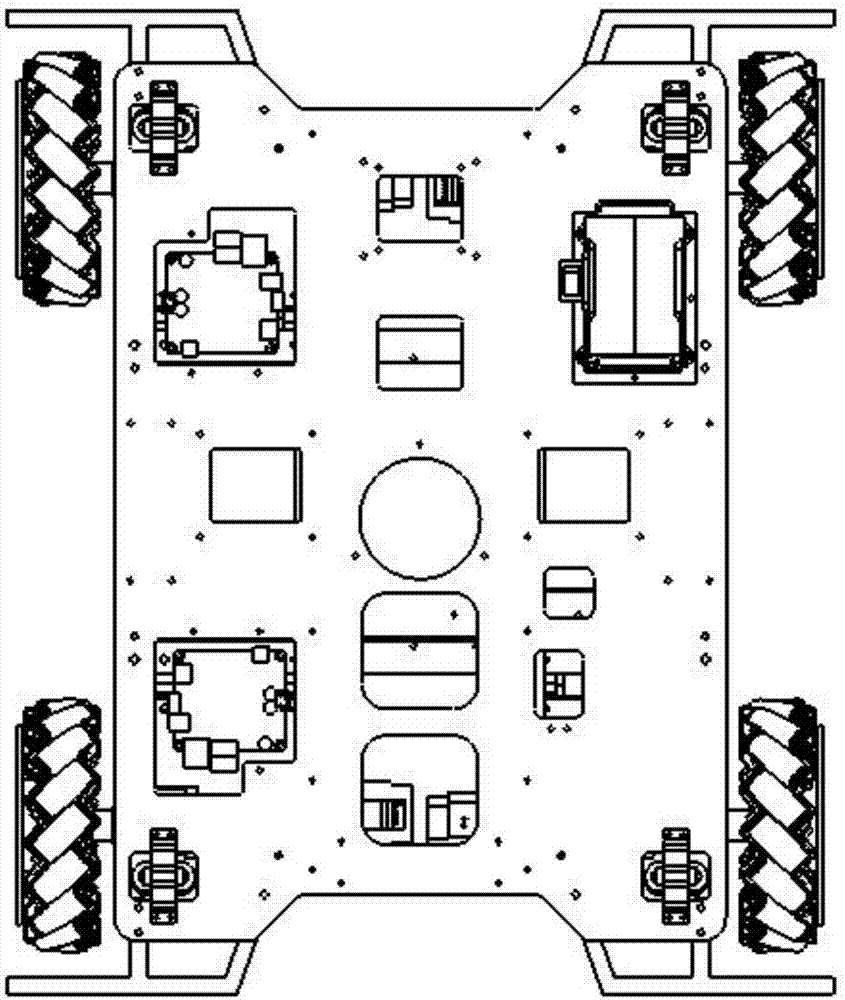

[0026] like Figures 1 to 5 shown. The invention discloses a robot chassis capable of omnidirectional movement and autonomous line inspection, comprising a chassis main board 1, a shock absorbing structure, an anti-collision mechanism 8, a power supply module, an automatic line inspection module, reinforcing ribs, a power system and a motor drive circuit board 16;

[0027] The chassis main board 1 is made of an acrylic plate, and there are reinforcing ribs fixed with bolts on the top and sides to enhance the rigidity of the mechanism; the reinforcing ribs include a panel reinforcing rib 2 and a side reinforcing rib 3; The ribs 2 are installed on the chassis main board 1 through bolts and nuts, and the side reinforcement ribs 3 are installed on the chassis main board 1 with the side facing downward. The ribs greatly enhance the rigidity of the overall mechanism.

[0028] The damping structure includes a suspension plate 4, a suspension mounting rod 5, a spring 6, and two spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com