Fertilization apparatus for agricultural planting

A fertilization device and agricultural technology, applied in the field of agricultural equipment, can solve problems such as the difficulty of automation equipment, the decline in output and economy, and the impact on the progress of fertilization, and achieve the effects of reducing labor workload, low manufacturing and maintenance costs, and increasing practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

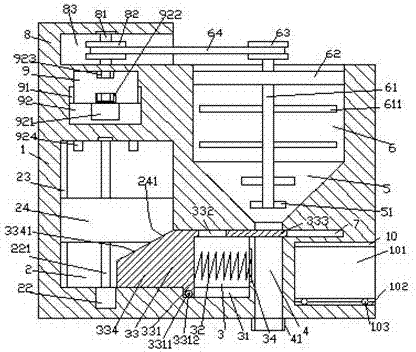

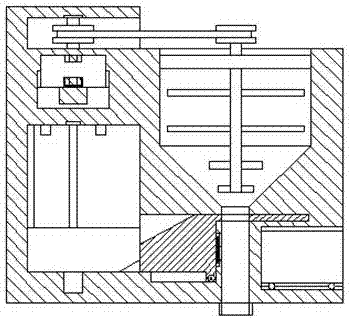

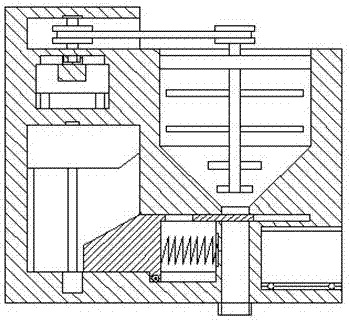

[0024] like Figure 1-Figure 5 As shown, a fertilization device for agricultural planting of the present invention includes a box body 1, a first sliding chamber 2 is provided inside the left side of the box body 1, and a first sliding chamber 2 is provided on the left inner wall of the first sliding chamber 2. A guide groove 23, the box body 1 on the right side of the first sliding chamber 2 is provided with a second sliding chamber 3 communicating with the first sliding chamber 2, the second sliding chamber The box body 1 on the right side of the chamber 3 is provided with a discharge groove 4 extending up and down, and the top of the second sliding chamber 3 is provided with a switch groove 7 that penetrates the discharge groove 4 and extends to the right. , the top of the discharge groove 4 is provided with a bucket-shaped part 5, the top of the bucket-shaped part 5 is provided with a feeding part 6, and the box 1 above the first sliding chamber 2 is provided with a third ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com