A cable winding device for power station construction

A winding device and cable technology, which is applied in the directions of transportation and packaging, thin material handling, and delivery of filamentous materials, etc. It can solve problems such as uneven winding, time-consuming and labor-intensive, and cables that cannot be pulled out for use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

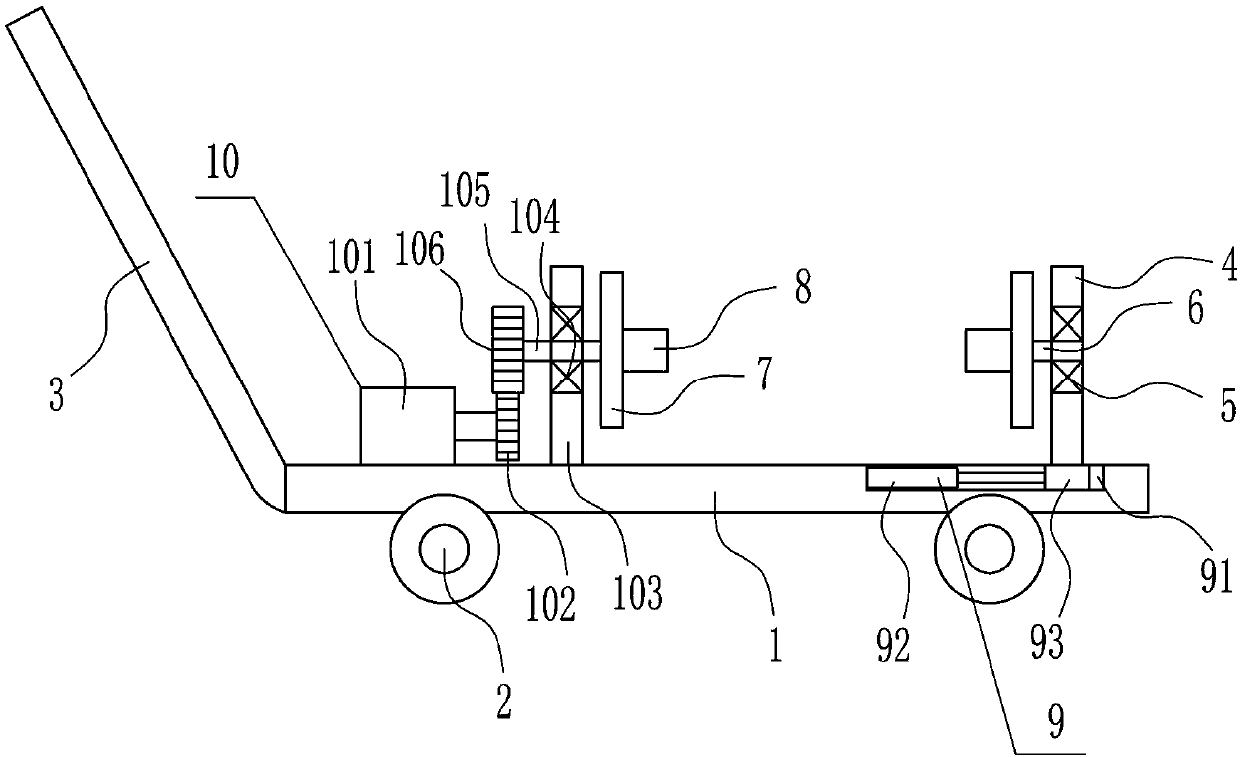

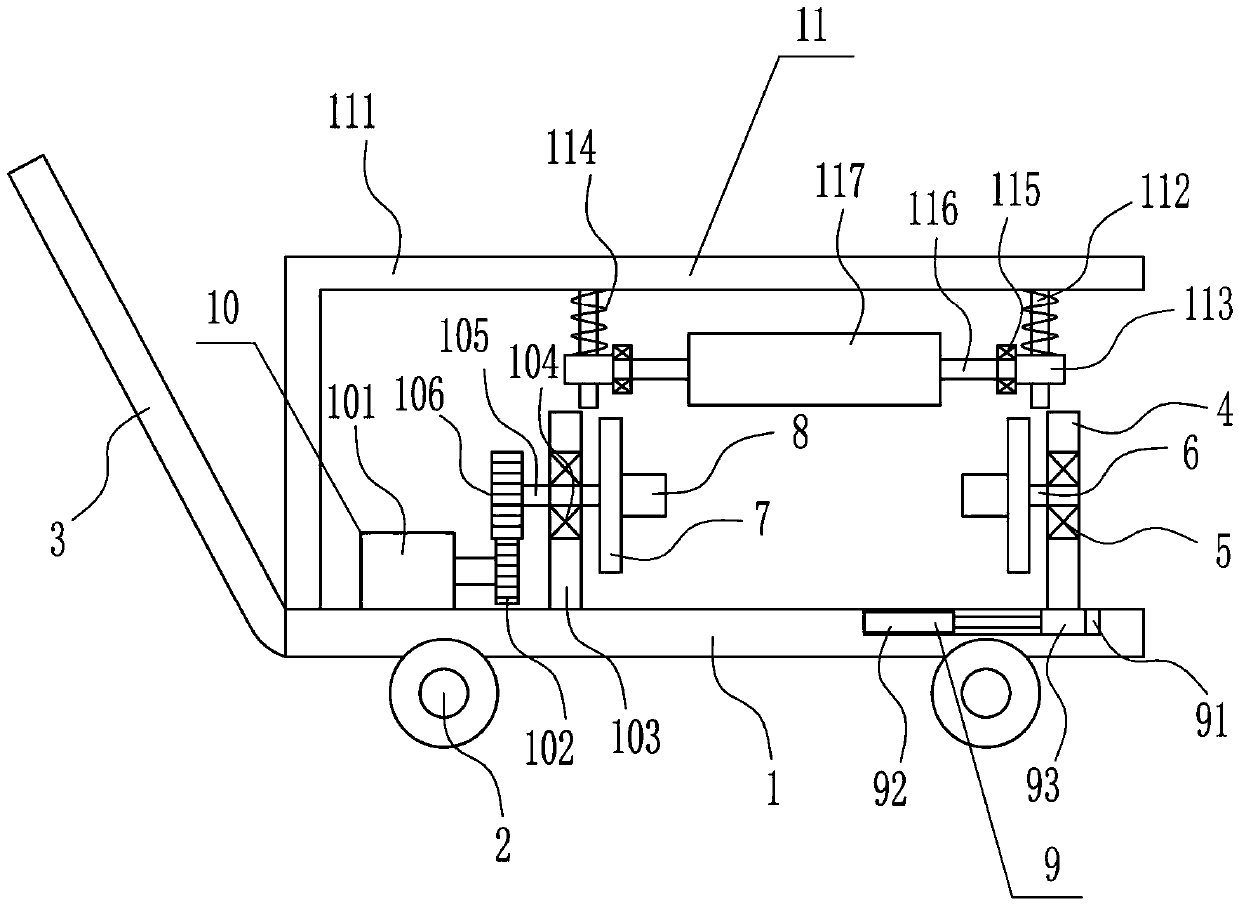

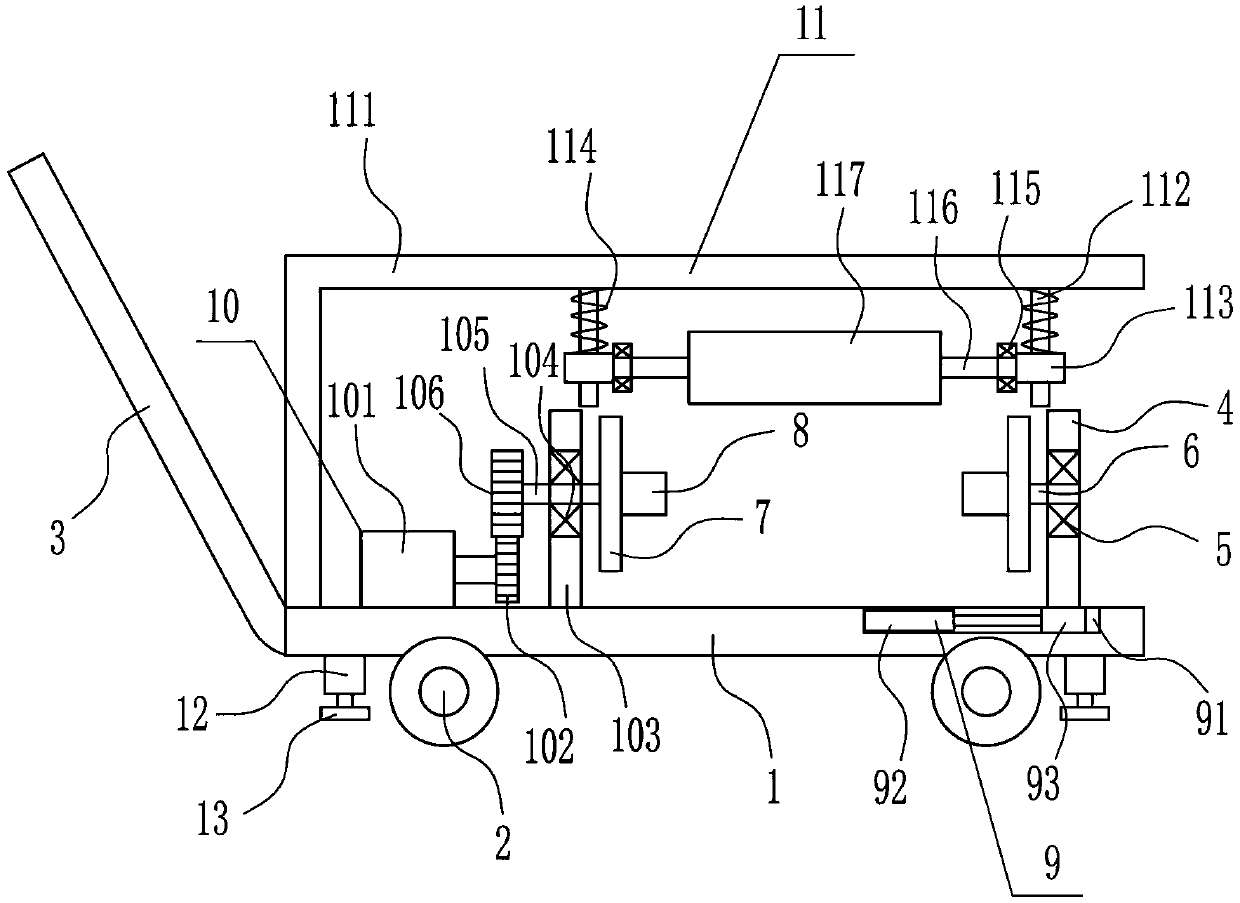

[0027] A cable winding device for power station construction, such as Figure 1-3 Shown, comprise base plate 1, wheel 2, push handle 3, first fixed plate 4, first bearing block 5, first rotating shaft 6, vertical plate 7, fixed post 8 and moving device 9, base plate 1 bottom left and right sides are all Wheels 2 are installed by means of bolt connection, and a push handle 3 is installed on the left side of the base plate 1 by means of bolt connection. The push handle 3 is arranged obliquely. There is a first fixed plate 4, a first bearing seat 5 is embedded in the middle of the first fixed plate 4, a first rotating shaft 6 is installed in the first bearing seat 5, and the first rotating shaft 6 is connected with the first rotating shaft through an interference connection. The bearings in the bearing housing 5 are connected, the left side of the top of the base plate 1 is provided with a rotating device 10, the rotating part of the rotating device 10 is connected with the left ...

Embodiment 2

[0029] A cable winding device for power station construction, such as Figure 1-3 Shown, comprise base plate 1, wheel 2, push handle 3, first fixed plate 4, first bearing block 5, first rotating shaft 6, vertical plate 7, fixed post 8 and moving device 9, base plate 1 bottom left and right sides are all Wheels 2 are installed by means of bolt connection, and a push handle 3 is installed on the left side of the base plate 1 by means of bolt connection. The push handle 3 is arranged obliquely. There is a first fixed plate 4, a first bearing seat 5 is embedded in the middle of the first fixed plate 4, a first rotating shaft 6 is installed in the first bearing seat 5, and the first rotating shaft 6 is connected with the first rotating shaft through an interference connection. The bearings in the bearing housing 5 are connected, the left side of the top of the base plate 1 is provided with a rotating device 10, the rotating part of the rotating device 10 is connected with the left ...

Embodiment 3

[0032] A cable winding device for power station construction, such as Figure 1-3 Shown, comprise base plate 1, wheel 2, push handle 3, first fixed plate 4, first bearing block 5, first rotating shaft 6, vertical plate 7, fixed post 8 and moving device 9, base plate 1 bottom left and right sides are all Wheels 2 are installed by means of bolt connection, and a push handle 3 is installed on the left side of the base plate 1 by means of bolt connection. The push handle 3 is arranged obliquely. There is a first fixed plate 4, a first bearing seat 5 is embedded in the middle of the first fixed plate 4, a first rotating shaft 6 is installed in the first bearing seat 5, and the first rotating shaft 6 is connected with the first rotating shaft through an interference connection. The bearings in the bearing housing 5 are connected, the left side of the top of the base plate 1 is provided with a rotating device 10, the rotating part of the rotating device 10 is connected with the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com