Soy protein spraying equipment and soy protein spraying method

A spraying equipment and soybean protein technology, applied in spraying devices, liquid spraying devices, etc., can solve problems such as uneven spraying and unstable product quality, increase powder accumulation, reasonable atomization coverage, and improve spraying uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Use a set of four nozzle spray guns of the present invention to carry out soybean protein spraying, concrete steps are as follows:

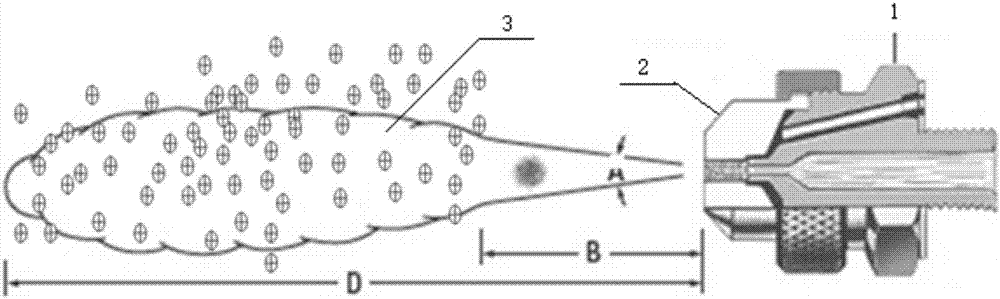

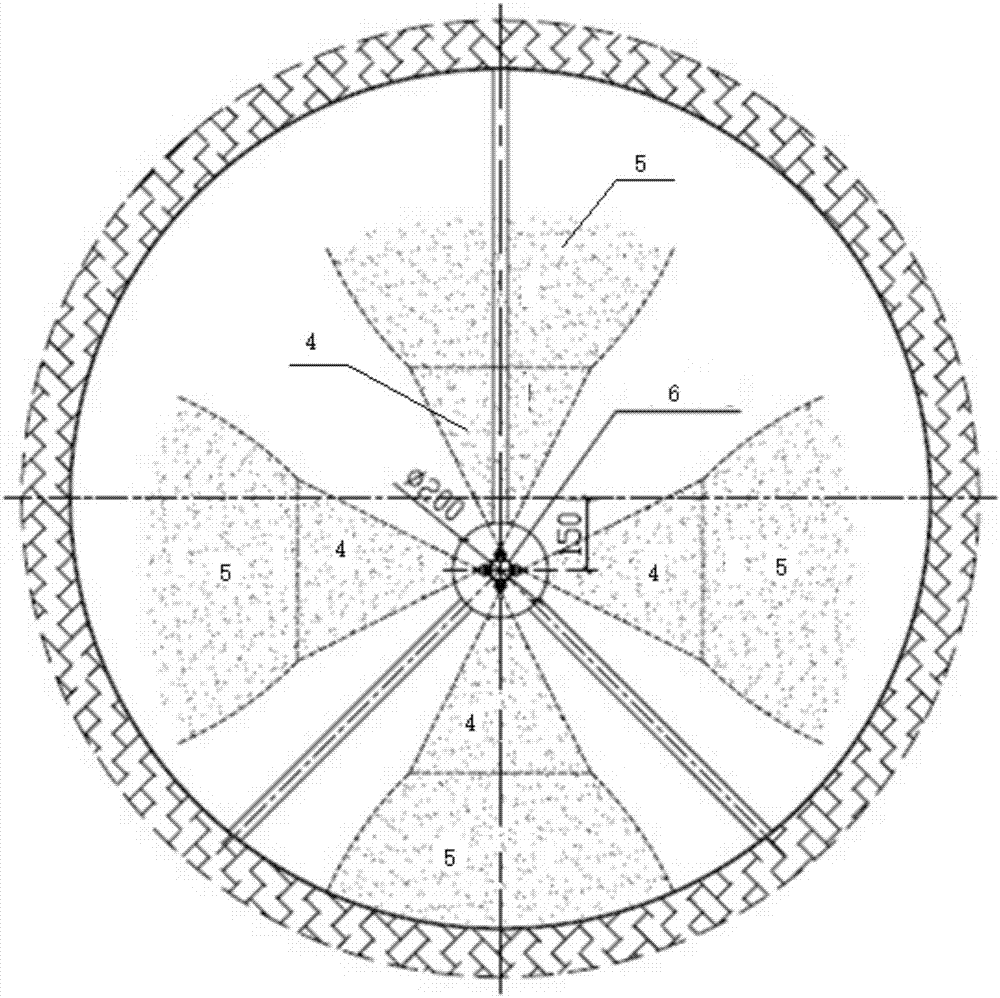

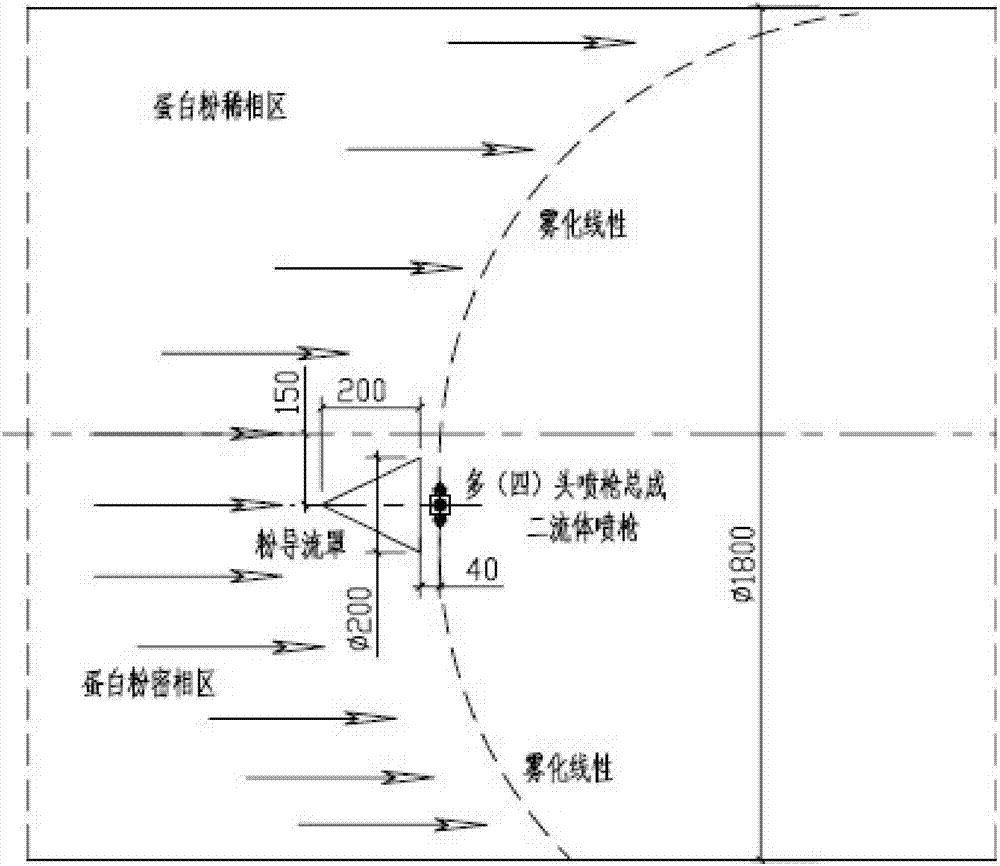

[0057] a. Spray gun distribution installation: Install a set of four nozzle spray guns on the upper side of the φ1800mm soybean protein recovery cylinder, the gun head falls at a suitable position in the powder dense phase area, and a conical powder shroud is set 40mm away from the front of the nozzle. Protect the fan-shaped surface atomized by the nozzle as designed Figure 2-3 As shown, the diameter of the conical bottom surface is φ200mm, and the height is h200mm. At the same time, make a bracket made of 304 material to fix the powder guide cover.

[0058] b. Production of spray guns: all welding is made of 304 material, all welded joints are ground and cleaned without slag inclusions, solder joints, etc., and the finish is Ra<0.6. The shroud is also made of 304 material, and the finish is Ra<0.3.

[0059] c. Spray gun installation: In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com