A Butler Matrix Network Structure Based on Dielectric Integrated Suspension Lines

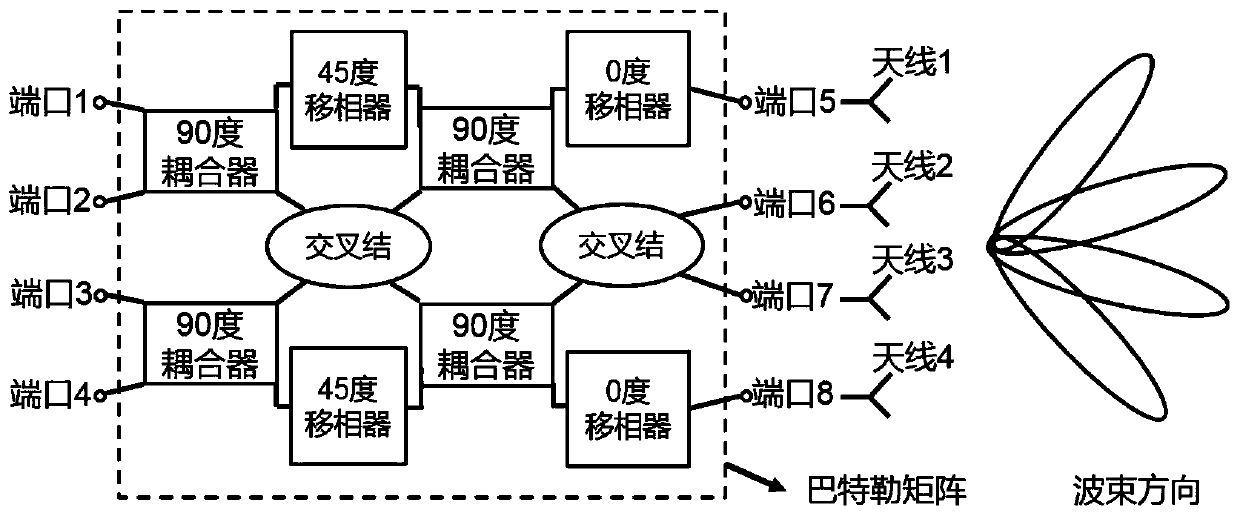

A Butler matrix and medium integration technology, applied in the field of Butler matrix network structure, can solve the problems of difficult circuit layout and large loss, and achieve the effects of low processing cost, low loss and reduction of radiation loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

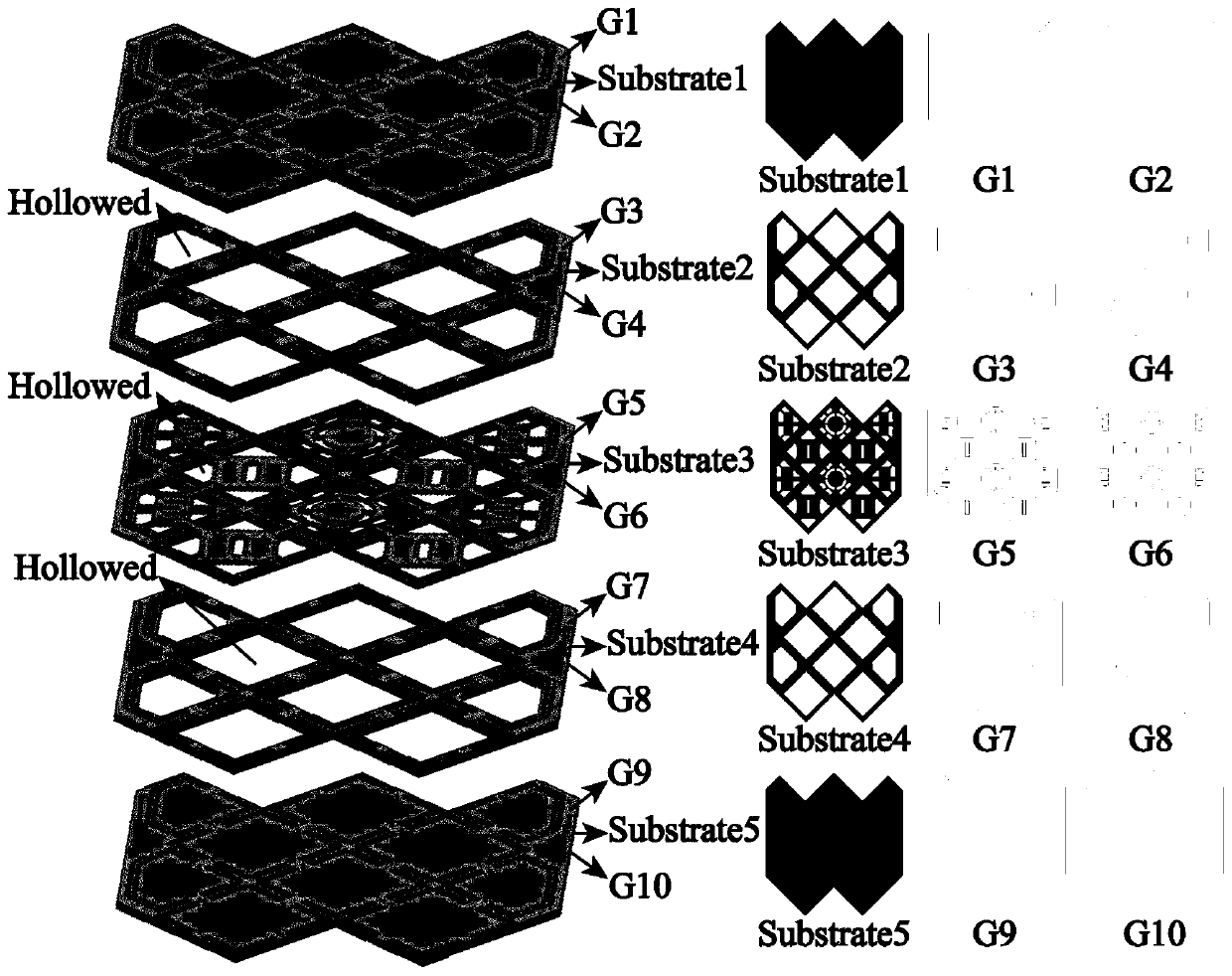

[0051] Embodiment 1: The five-layer dielectric substrate is selected as:

[0052] Substrate1: Fr4 material, thickness 0.6mm, dielectric constant 4.4;

[0053] Substrate2: Fr4 material, thickness 0.6mm, dielectric constant 4.4;

[0054] Substrate3: Rogers5880 material, plate thickness 0.25mm, dielectric constant 2.2;

[0055] Substrate4: Fr4 material, thickness 0.6mm, dielectric constant 4.4;

[0056] Substrate5: Fr4 material, thickness 0.6mm, dielectric constant 4.4;

[0057] The design frequency band of the Butler matrix is: the center frequency is 25.45GHz, and the bandwidth is 24.5GHz-26.5GHz.

[0058] G1 to G10 are ten metal layers. Can be copper clad or gold plated.

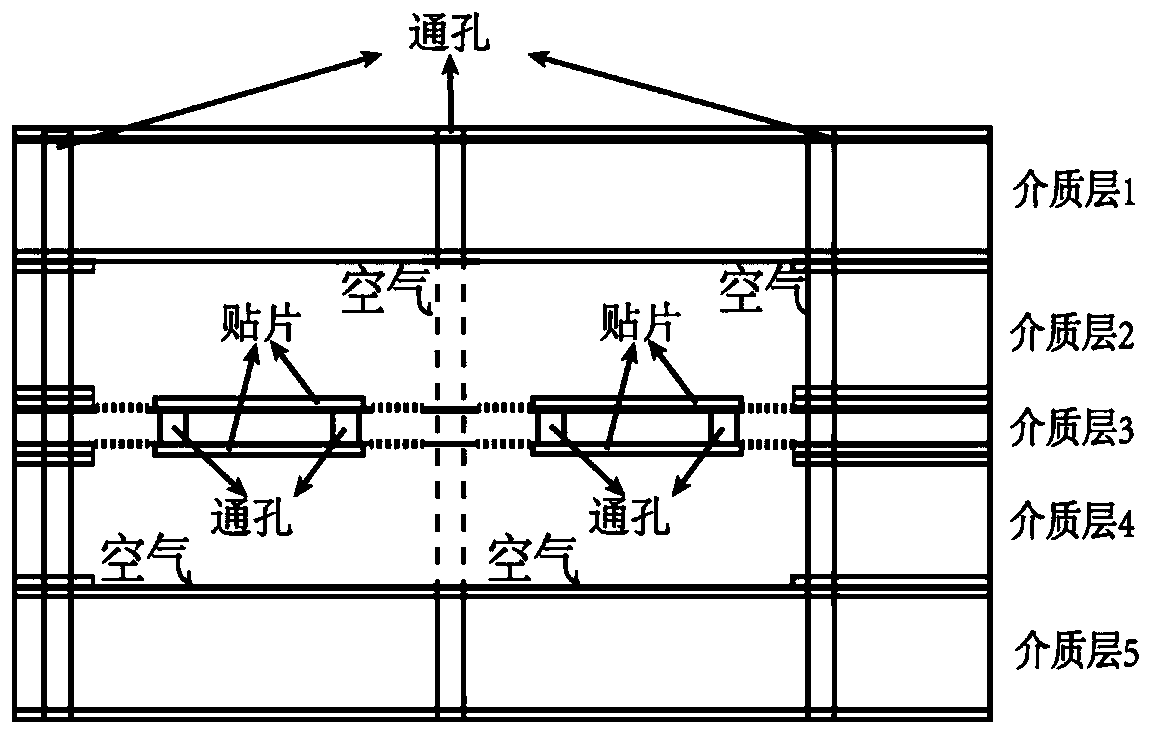

[0059] Both the coupler and the cross junction adopt a patch-shaped structure, and the phase shifter adopts a bent-line structure. In order to reduce the loss of the circuit, we proceed from three aspects: radiation loss, conductor loss, and dielectric loss. As shown in the cross-sectional view, all t...

Embodiment 2

[0061] The five-layer dielectric substrate is selected as:

[0062] Substrate1: Fr4 material, thickness 0.6mm, dielectric constant 4.4;

[0063] Substrate2: Fr4 material, thickness 0.6mm, dielectric constant 4.4;

[0064] Substrate3: Rogers5880 material, plate thickness 0.25mm, dielectric constant 2.2;

[0065] Substrate4: Fr4 material, thickness 0.6mm, dielectric constant 4.4;

[0066] Substrate5: Fr4 material, thickness 0.6mm, dielectric constant 4.4;

[0067] The design frequency band of the Butler matrix is: the center frequency is 25.45GHz, and the bandwidth is 24.5GHz-26.5GHz.

[0068] Both the coupler and the cross junction adopt a patch-shaped structure, and the phase shifter adopts a bent-line structure. Antennas are also implemented on the SISL platform. In order to reduce the loss of the circuit, we proceed from three aspects: radiation loss, conductor loss, and dielectric loss. Finally adding the transition section has been tested as Figure 9 shown. For th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com