Radiant heat exchange structure and radiator applying same

A technology of radiation heat exchange and radiator, which is applied in the field of radiation heat exchange, can solve the problem of small radiator heat transfer, achieve the effect of improving anti-condensation performance and slowing down the formation of condensation water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

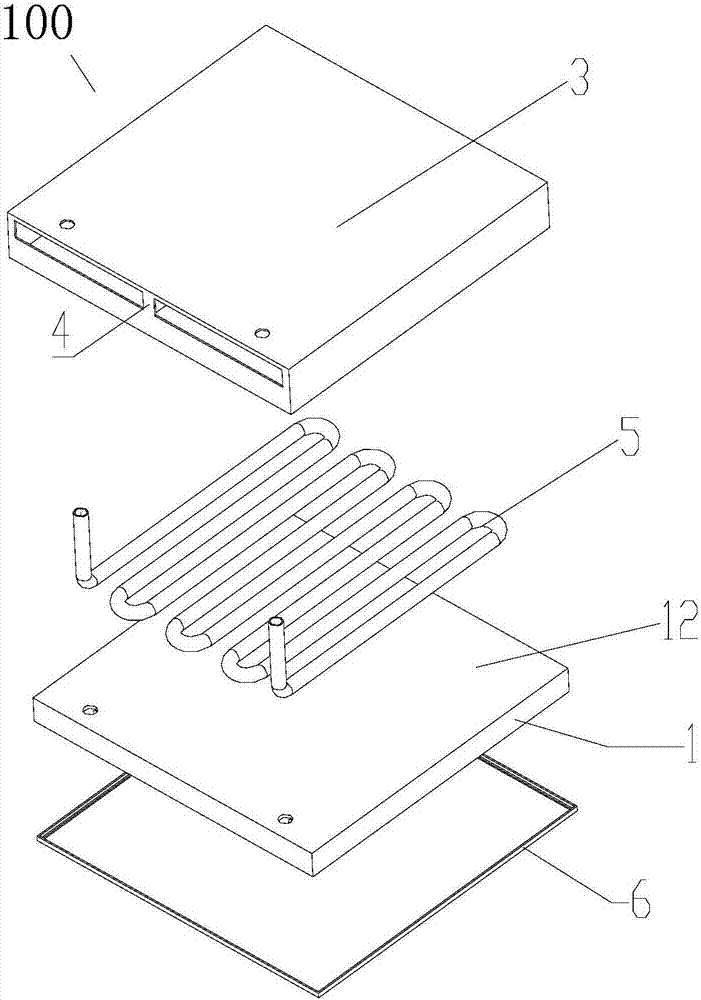

[0042] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the application according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. . In the following description, different "one embodiment" or "embodiment" do not necessarily refer to the same embodiment. Furthermore, the particular features, structures, or characteristics of one or more embodiments may be combined in any suitable manner.

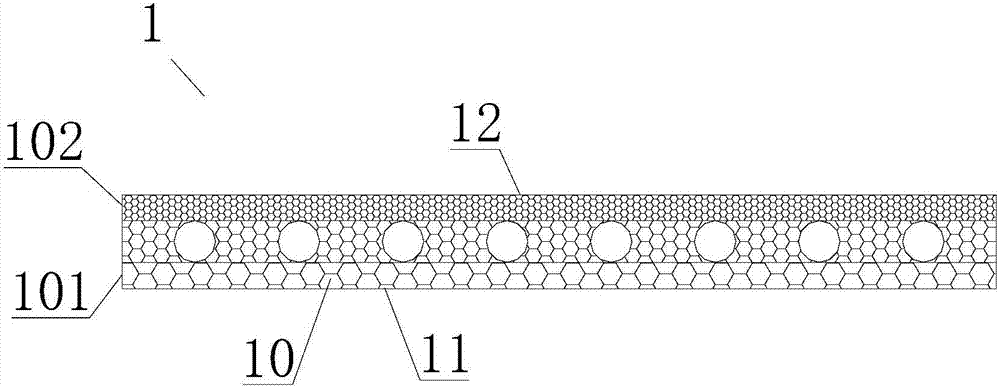

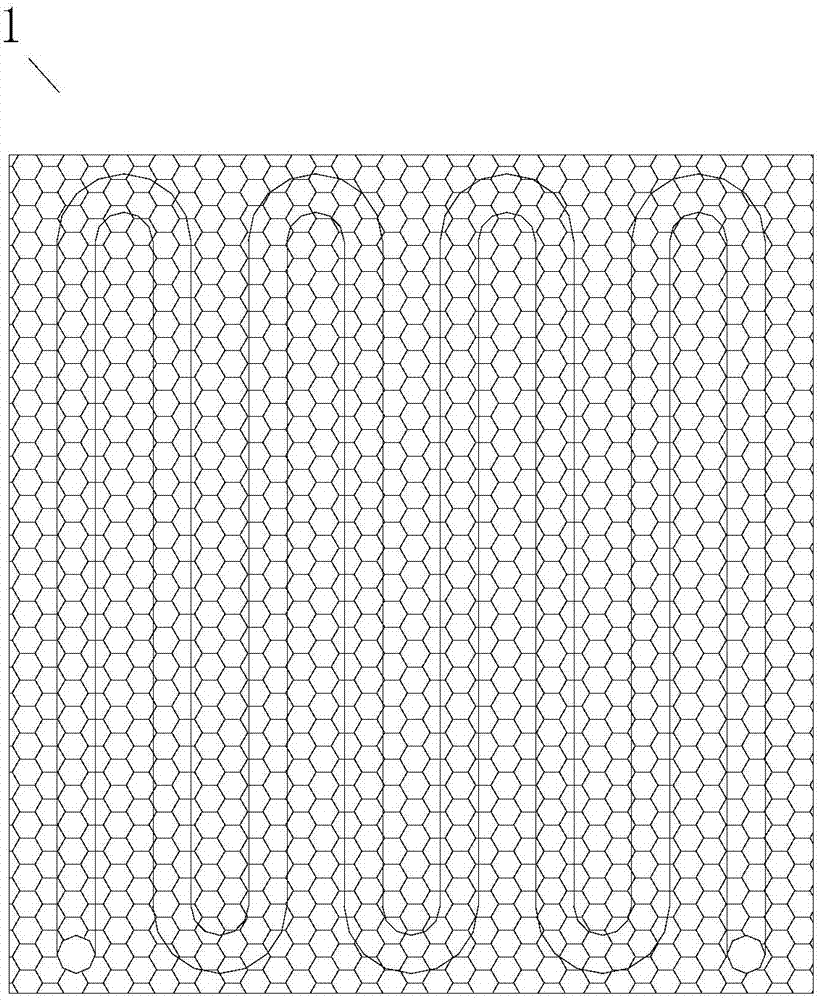

[0043] Such as figure 1 with figure 2 As shown, an embodiment of the present invention proposes a radiation heat exchange structure, including a radiation element 1 . The radiation element 1 has a radiation surface 11 . The radiating element 1 is provided with a capillary channel 10 having a capillary effect, and the capillary channel 10 extends from the rad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com