Electric size push broach assembly

A technology of knife assembly and size, which is applied in metal processing and other directions, can solve problems such as wasting time, reducing work efficiency, and not having dimensional measurement and electric functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

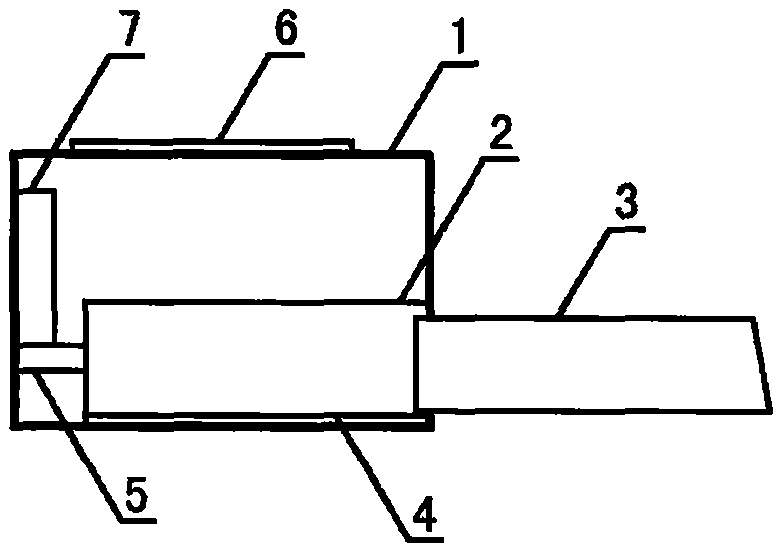

[0012] Embodiment: as shown in the accompanying drawing. An electric size push knife assembly, comprising a frame body (1), a base (2) is arranged inside the frame body, a blade (3) can be arranged in the base, the blade is installed inside the base, and the required blade can be replaced by itself according to the demand, and the base Embedded and fixed inside the frame body.

[0013] An electric size pushing knife assembly is provided with a moving track (4) under the base, which can facilitate the pushing, retracting and moving of the blade in any size on the track.

[0014] An electric size pushing knife assembly is provided with a pushing module (5) behind the base, which can push the blade out or retract the blade to a specified size during operation.

[0015] An electric size pushing knife assembly is provided with a setting panel (6) on the surface of the frame body, which can set the pushing or retracting size of the blade by itself.

[0016] An electric size pushin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com