Oil storage tank side wall cleaning equipment and oil storage tank including same

A technology for cleaning equipment and oil storage tanks, which is applied to cleaning hollow objects, cleaning methods and utensils, and cleaning methods using tools, etc. Cleaning efficiency and avoidance of sludge accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Specific embodiments of the present invention will be illustrated below with reference to the accompanying drawings.

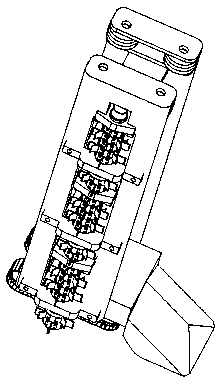

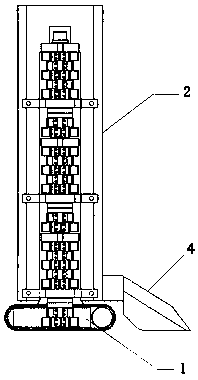

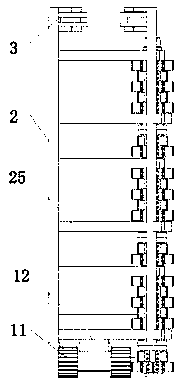

[0038] refer to Figure 1-7 An embodiment of the equipment for cleaning the side wall of the oil storage tank of the present invention will be described in detail. Such as Figure 1-4 As shown, the cleaning equipment for the side wall of the oil storage tank includes: a chassis 1 , a main body of the cleaning equipment 2 , a guide wheel 3 , and a countersink 4 .

[0039] Chassis 1 comprises running gear 11 and base plate 12, and base plate is fixed on the running gear 11, is used for supporting cleaning equipment main body 2, and running gear 11 can be crawler type running gear, also can be wheel type running gear, under the drive of motor, The running gear 11 can move arbitrarily on the bottom surface of the oil storage tank. In this embodiment, a crawler-type traveling device is adopted, such as commonly used in traveling machinery, and the crawler...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com