A large-volume concrete temperature control device and temperature control method

A technology of mass concrete and temperature control method, applied in the direction of temperature control, control/regulation system, non-electric variable control, etc., can solve the problem of not realizing all-round control of temperature, and ensure product quality, safety and stability The effect of sexual security and flexible regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

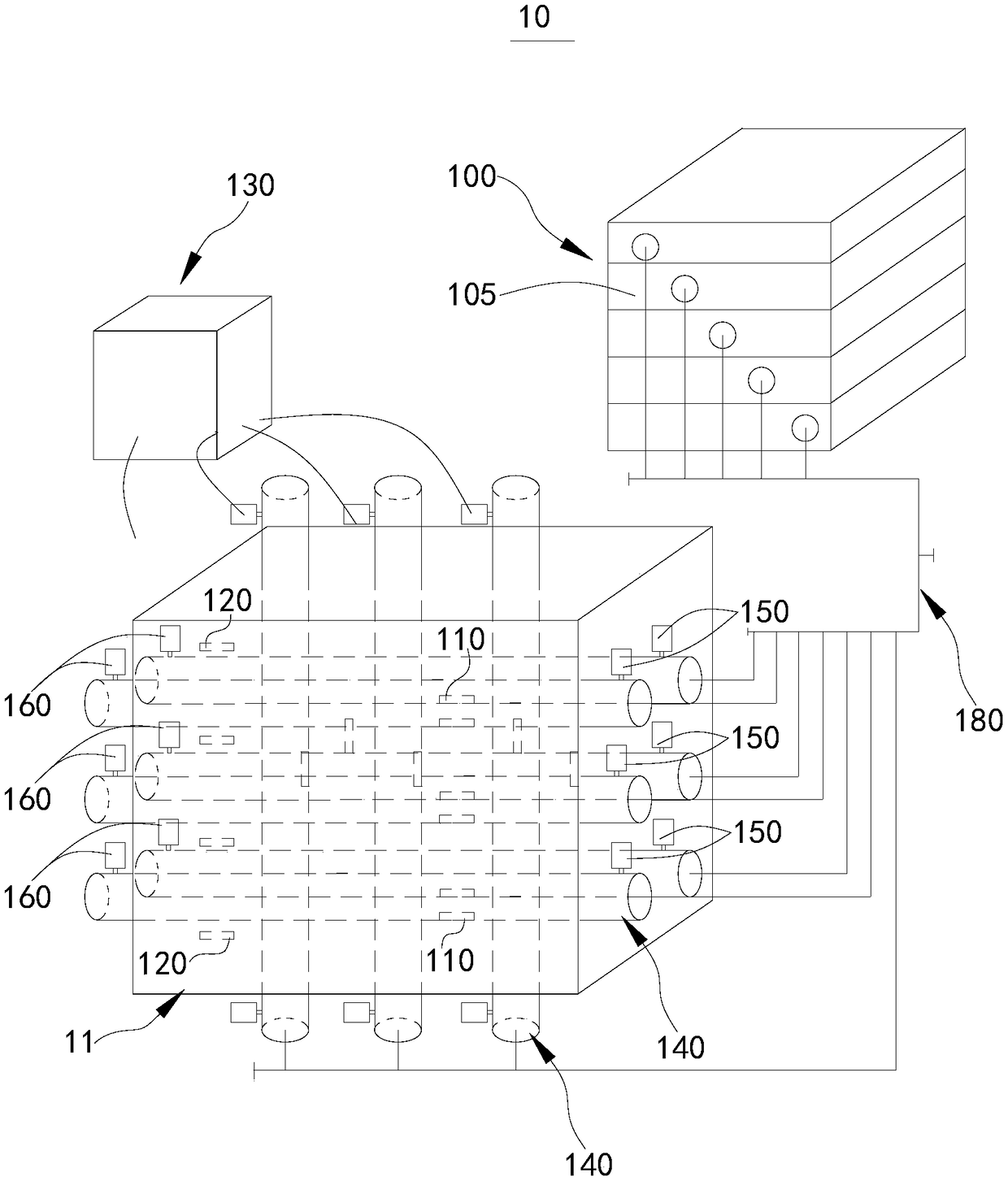

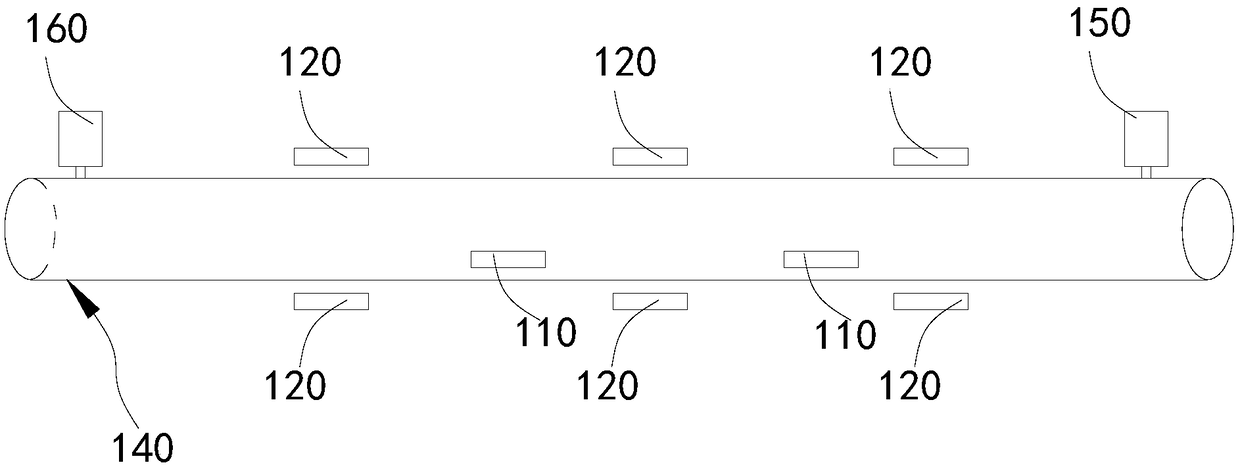

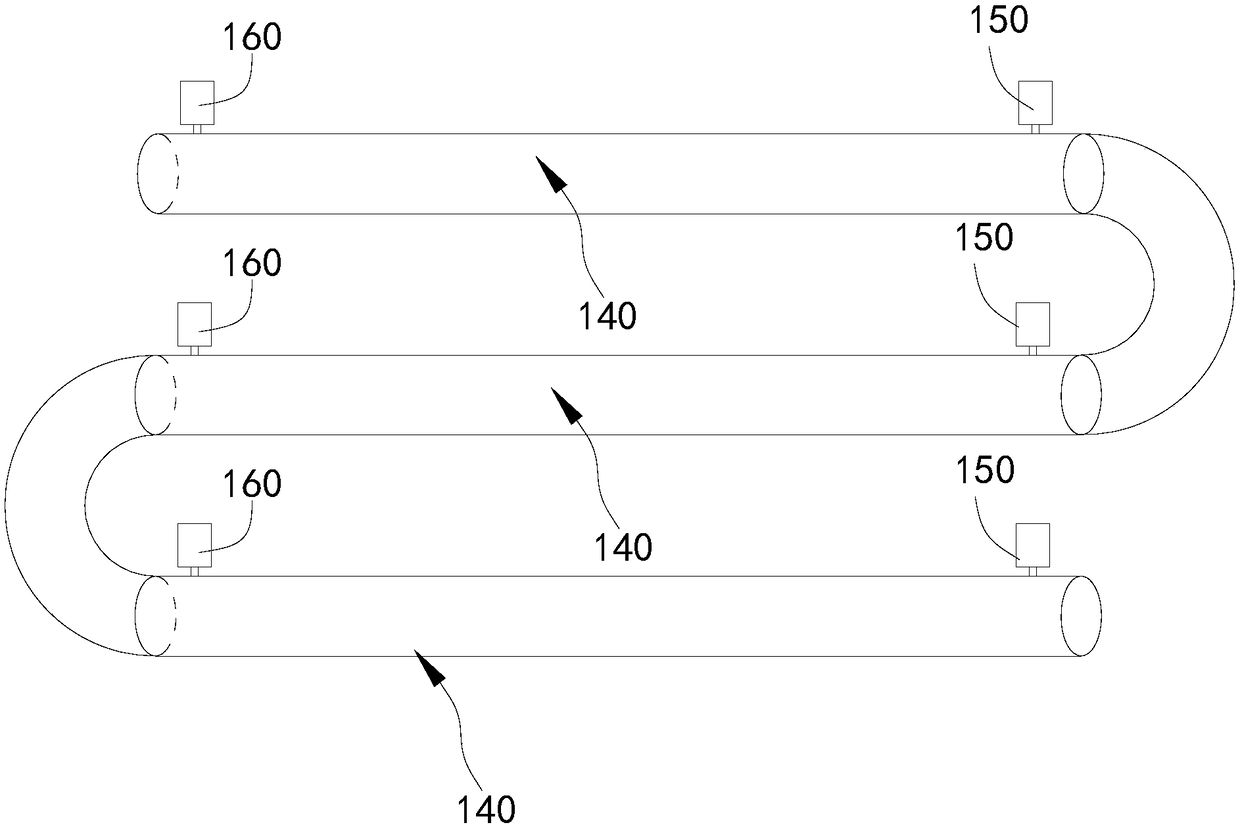

[0051] Please refer to figure 1 , figure 1 A structural schematic diagram of a large-volume concrete temperature control device 10 is provided for this embodiment of the present invention, from figure 1 It can be seen from the figure that the large-volume concrete temperature control device 10 includes a water tank 100 , a control device 130 , a plurality of branch water pipes 140 , a plurality of first temperature sensors 110 and a plurality of second temperature sensors 120 .

[0052] The branch water pipe 140, the first temperature sensor 110 and the second temperature sensor 120 are all located inside the mass concrete 11; the water tank 100 has a plurality of mutually divided water storage spaces 105, and the water storage space 105 has corresponding branch water pipes 140; A plurality of water storage spaces 105 are configured to accommodate fluids of different temperatures; the inlets of the plurality of branch water pipes 140 are all provided with a first regulating v...

Embodiment 2

[0064] Please refer to Figure 4 , Figure 4 A schematic diagram of a temperature control method is provided for this embodiment. Please combine figure 1 Mass concrete temperature control equipment 10 to understand the working principle of the temperature control method.

[0065] A temperature control method, the temperature control method is realized based on any one of the above-mentioned mass concrete temperature control equipment 10; the temperature control method includes the following steps:

[0066] Installation steps: setting the branch water pipe 140, the first temperature sensor 110 and the second temperature sensor 120 in the mass concrete 11;

[0067] Preliminary temperature control step: according to the temperature information fed back by the second temperature sensor 120, the control device 130 controls the first regulating valve 150 so that the water tank 100 injects a preset volume of fluid into each branch water pipe 140;

[0068] Advanced temperature con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com