Automatic filling and leveling device for road cracks

An automatic filling and cracking technology, applied in the field of municipal engineering, can solve the problems of uneven surface, many users, waste of labor, etc., and achieve the effect of less labor, easy operation, and guaranteed road surface

Active Publication Date: 2017-10-20

珠海交通工程技术有限公司 +1

View PDF6 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Traditionally, for the cracks on the road surface, some asphalt is poured on the surface to fill the cracks, but traditionally, after filling, the surface is uneven, and passing vehicles will also bump along with the unevenness, and the traditional The pouring did not enter the inside of the material, and the sticky effect is not good. If artificial filling is performed, someone needs to walk along the gap with the discharge pipe in front, and someone needs to push or drive a vehicle carrying the material liquid behind. Coordinated operation requires many users and wastes labor. Therefore, in order to make the ground more stable and reliable, and to reduce the use of personnel, it is necessary to design a device that can be operated by a single person and has a good filling effect.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0023] Embodiment 2: The telescopic effect can also be achieved by replacing the electronically controlled telescopic rod 24 with a linear motor, and other structures are the same as in Embodiment 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

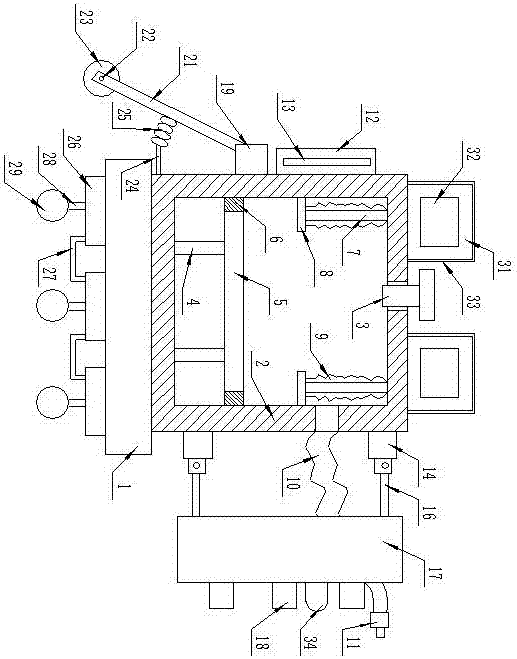

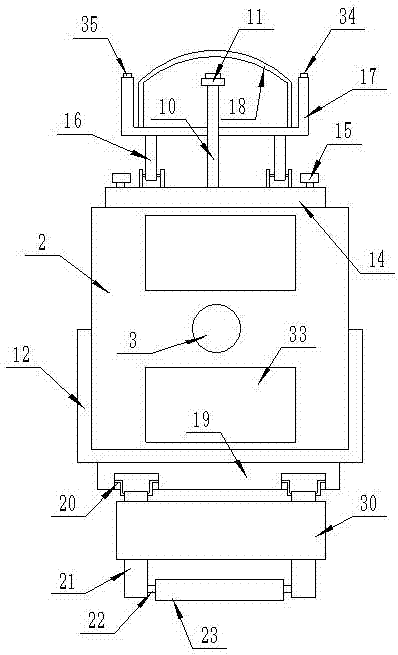

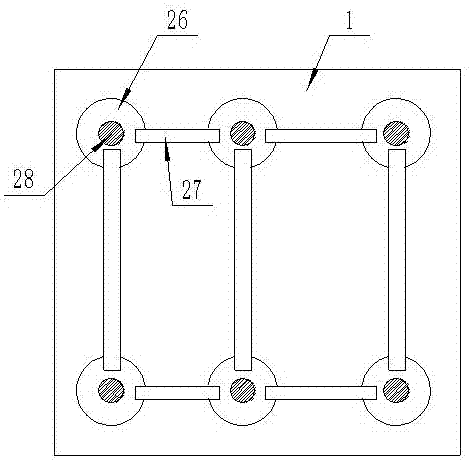

The invention discloses an automatic filling and leveling device for road cracks. The device comprises a rectangular bearing pedestal, the upper surface of the rectangular bearing pedestal is fixedly connected with a rectangular bearing box body, a filling liquid bearing and discharging mechanism is arranged in the rectangular bearing box body, the front surface of the rectangular bearing box body is provided with a pulling mechanism, the rear surface of the rectangular bearing box body is provided with a leveling mechanism, and the lower surface of the rectangular bearing pedestal is provided with a moving mechanism. The device has the advantages of convenience in use, small labor force, convenience in one-man operation, accuracy in crack filling, good surface leveling effect, good adhesion effect and guaranteeing of the firmness of pavements.

Description

technical field [0001] The invention relates to the technical field of municipal engineering, in particular to automatic filling and smoothing equipment for road cracks. Background technique [0002] For roads, since the paving materials used are granular, long-term rolling or lack of water will easily cause cracks on the surface. [0003] Traditionally, for the cracks on the road surface, some asphalt is poured on the surface to fill the cracks, but traditionally, after filling, the surface is uneven, and passing vehicles will also bump along with the unevenness, and the traditional The pouring did not enter the inside of the material, and the sticky effect is not good. If artificial filling is performed, someone needs to walk along the gap with the discharge pipe in front, and someone needs to push or drive a vehicle carrying the material liquid behind. Coordinated operation requires many users and wastes labor. Therefore, in order to make the ground more stable and relia...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E01C23/09

CPCE01C23/098

Inventor 蒋旭

Owner 珠海交通工程技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com