White oil production line

A technology of production line and white oil, which is applied in the processing of hydrocarbon oil, petroleum industry, hydrotreating process, etc. It can solve the problems of unfavorable catalyst contact with tail oil and hydrogen, slow down production line beat, unfavorable sealing design, etc., to achieve good practicality value, speed up reaction fission process, and reduce cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

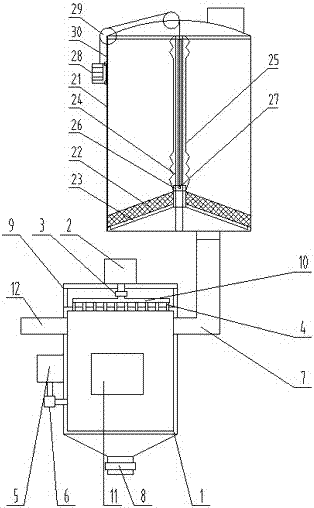

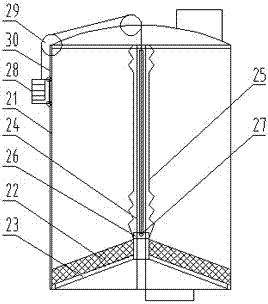

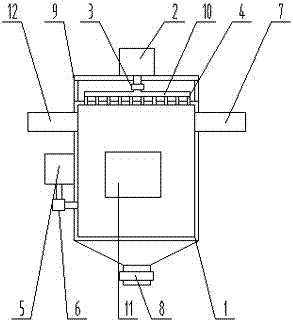

[0014] As shown in the accompanying drawings, the present invention includes a filter storage tank and a hydrogenation reactor, and the filter storage tank includes a filter storage tank body 21, a double-layer conical filter screen 22, a filter screen support frame 23 and a filter screen lifting device, The top of the filter storage tank body 21 has an oil inlet, and the bottom has an oil outlet. The filter storage tank body 21 is vertically provided with a guide rod 24. The guide rod 4 is a hollow tube, and the tube wall of the hollow tube There is a pair of long holes symmetrically on the top, and the guide rod 4 is covered with a telescopic tube 25; the filter screen support frame 23 is provided with a guide sleeve 26 used in conjunction with the guide rod 4, and the guide sleeve 26 is provided with a pair of long holes. Cooperate with the positioning rod 27 used, the filter screen support frame 23 is movably installed on the guide rod 4 through the guide sleeve 26, and one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com