A rotary trigger device and vertical intelligent steel coil fixture

A technology for triggering devices and clamps, which is applied in the directions of safety devices, transportation and packaging, and load hanging components, etc. It can solve the problems of large impact force, control signal, fast clamp lifting speed and unable to clamp steel coils, etc., and achieves strong impact resistance , Strong environmental adaptability, avoiding the effect of unstable speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

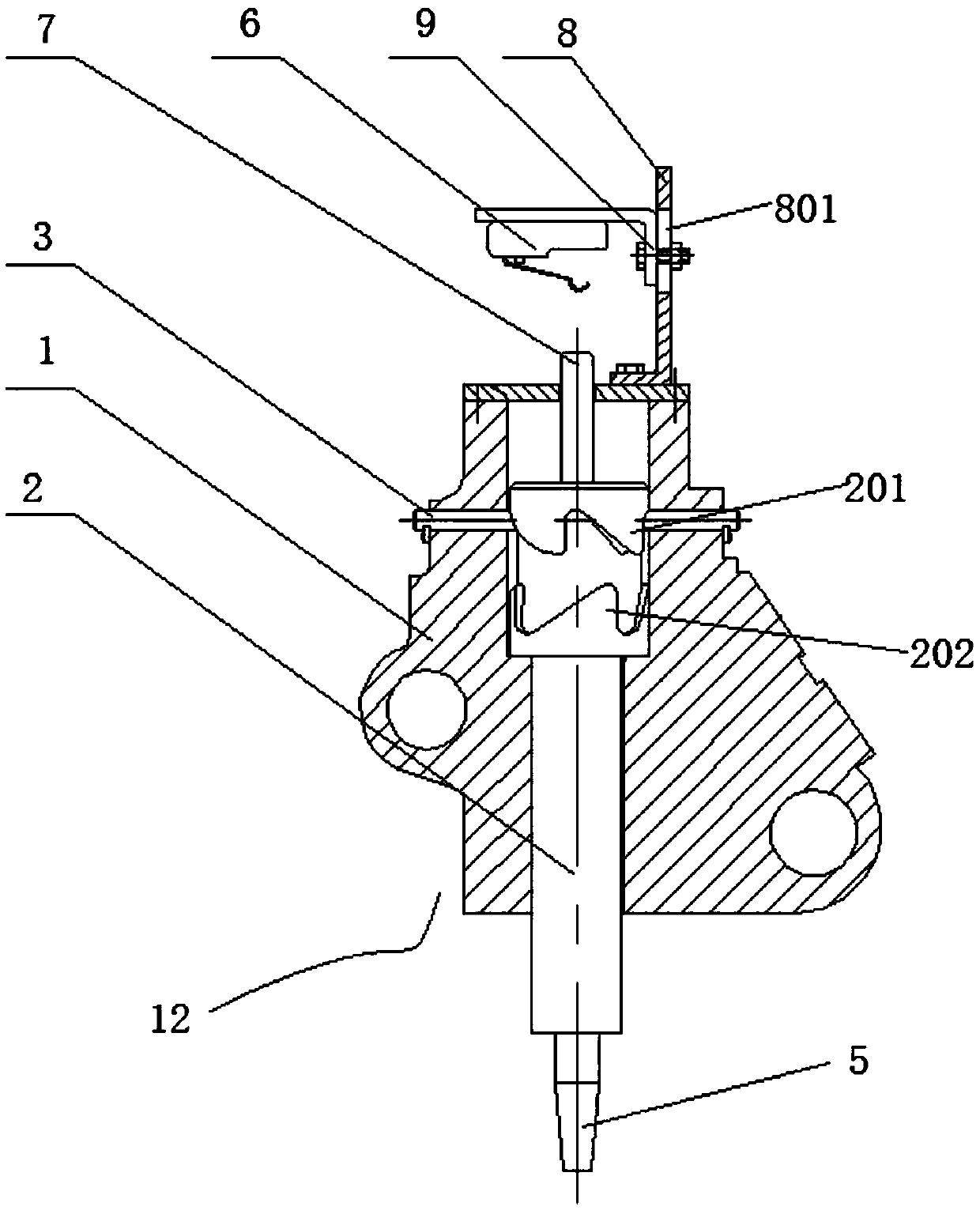

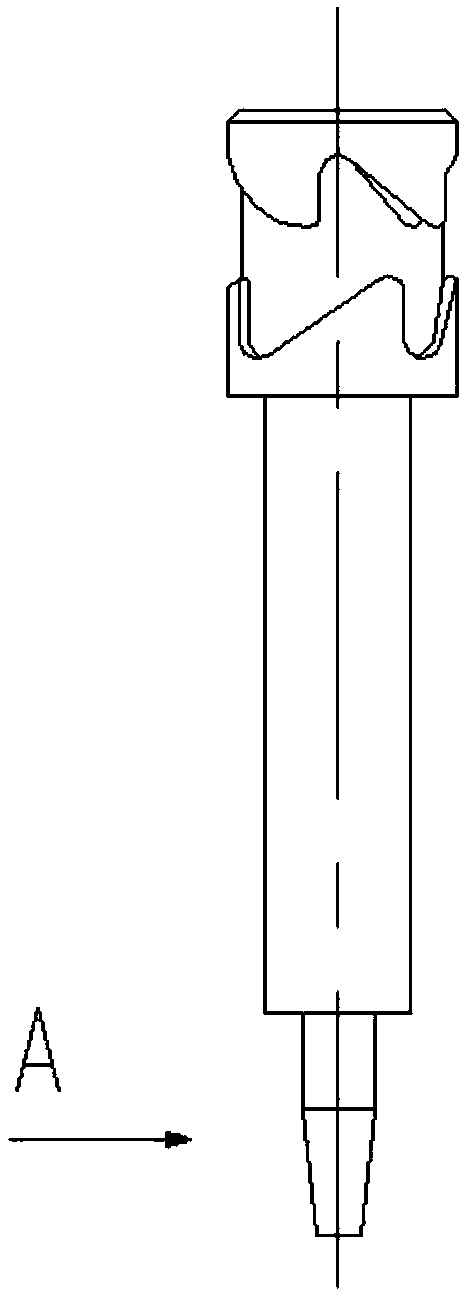

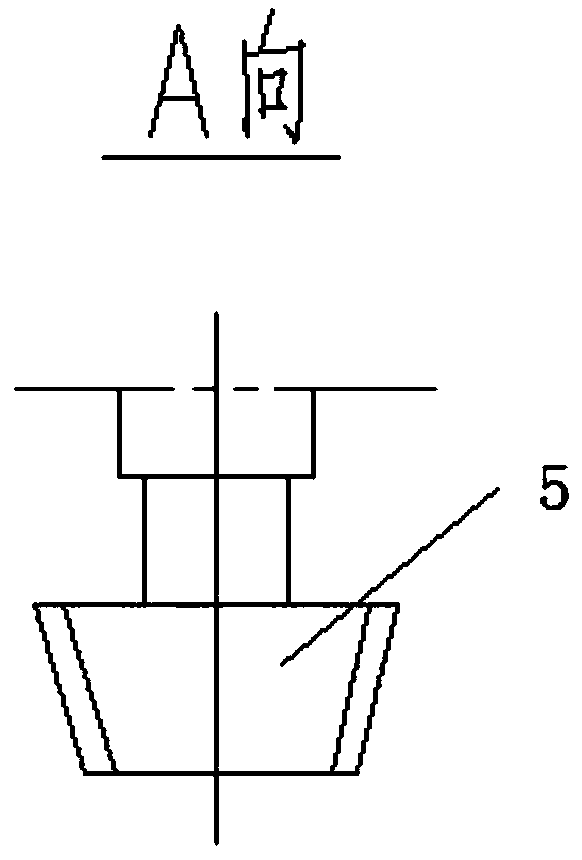

[0028] Such as figure 1 Shown is a rotary trigger device 12 of the present invention, which includes a housing 1, a feeler rod 2, a pin shaft 3, and a lift limit switch 4. The pin shafts 3 in this embodiment are two, which are symmetrically arranged on both sides of the feeler rod . The contact rod 2 is slidingly connected with the housing 1, the upper part of the contact rod 2 is provided with an upwardly inclined groove 201 and a downwardly inclined groove 202 arranged in dislocation, the lower part of the contact rod is provided with a contact 5, and the pin shaft One end of 3 is fixed on the housing 1, and the other end is located between the upward slope groove 201 and the downward slope groove 202. The lifting limit switch 4 is arranged below the contact 5, and the pin shaft 3 is connected to the housing 1 together. Lifting, driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com