Table-foot structure of rack

A table foot and rack technology, applied in the field of table foot structure of racks, can solve problems such as affecting production safety and efficiency, affecting shoe buttons, affecting production efficiency, etc., achieving convenient operation, solving unstable placement and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

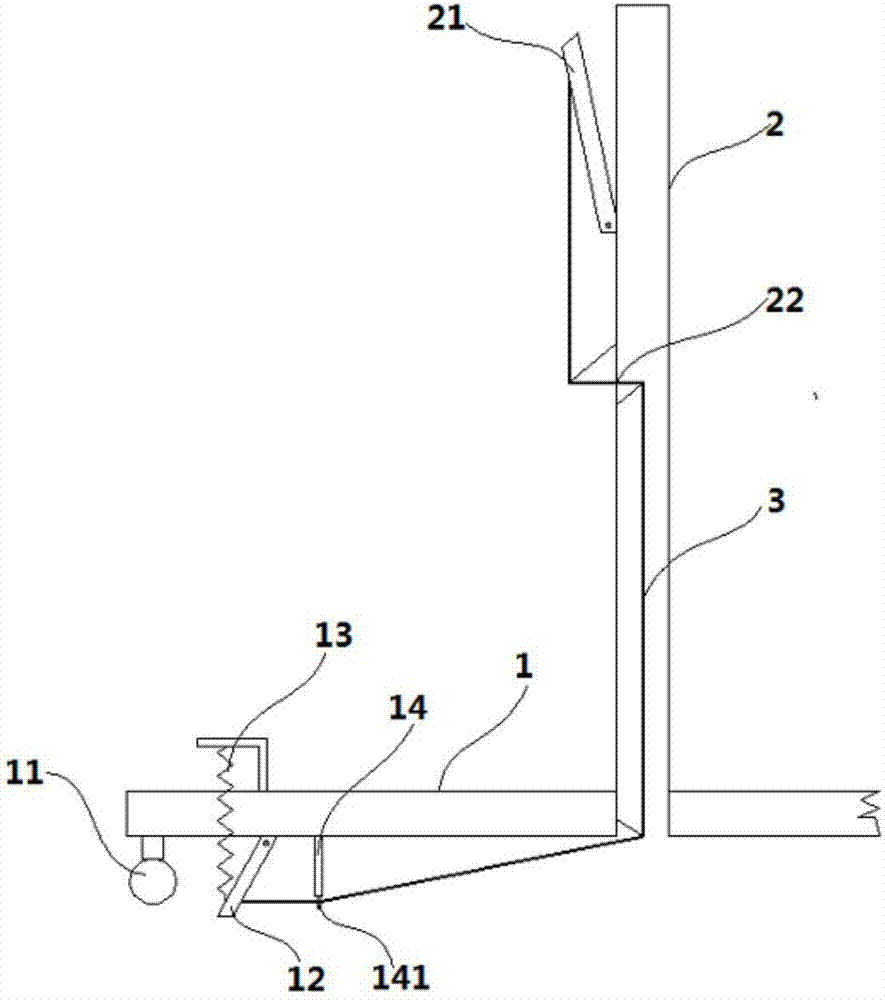

[0014] A table leg structure for a rack, such as figure 1 As shown, it includes a support rod 2 fixed on the top of the table leg 1. Four pulleys 11 are installed at the bottom of the table leg 1. A leg 12 is arranged beside the pulley 11. The length of the leg 12 is greater than the height of the pulley 11. The upper end of the leg 12 is It is fixed on the bottom of the table leg 1 by means of a hinge, and the leg 12 is tightened and laterally attached to the bottom of the table leg 1 by the spring 13 fixed on the table leg 1, and a pole is provided on the bottom of the table leg 1 next to the leg 12 14. The bottom of the pole 14 is provided with a ring 141, one end of the rope 3 passes through the ring 141 and is fixed on the foot 12, and the other end of the rope 3 is fixed on the handle 21 on the support rod 2, and the handle 21 passes through the The mode of hinge is fixed on support bar 2, and rope 3 is tensioned state, pulls pull handle 21 upwards, and supporting foot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com