Building method of modularized shielding room and modularized shielding room

A construction method and technology of shielding room, which can be used in building structures, buildings, small buildings, etc., can solve problems such as a large amount of dust, harmful volatiles, delaying construction period, affecting the progress of the project, etc., to facilitate standardized management and assembly of parts and components. Simple, no lasting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

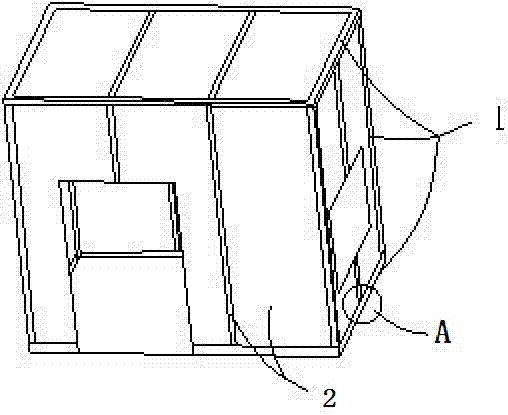

[0050] Such as figure 1As shown, a modular shielding room is provided, including a rectangular parallelepiped shielding room frame structure built with corner keels 1, and a shielding module 2 embedded in the overall frame of the shielding room. Specifically, the rectangular parallelepiped shielding room frame structure and the shielding module 2 form a semi- Closed shielded room.

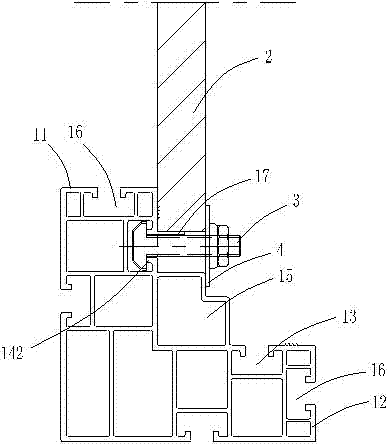

[0051] such as zoom in figure 2 As shown, the shielding room of this embodiment adopts the overall load-bearing of the corner keel 1, and the shielding module 2 does not contact the ground, so as to realize the overall modular design of the shielding room.

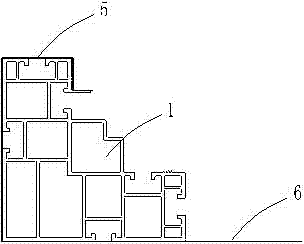

[0052] The corner keel 1 is spliced at the corner of the top corner of the rectangular parallelepiped shielding room frame structure at a bevel angle of 45°, specifically the joint of the corner joist on the top and bottom surfaces of the rectangular parallelepiped frame structure.

[0053] Such as image 3 As shown, the cross section of ...

Embodiment 2

[0069] Based on the modular shielding room of embodiment 1, this embodiment provides a construction method of a modular shielding room, such as Figure 6 shown, including the following steps:

[0070] S1. Ground treatment: Lay waterproof and moisture-proof materials and insulation layers on the ground. The waterproof and moisture-proof materials include SBS waterproof and moisture-proof layers 7 and moisture-proof plastic film layers 8 arranged in sequence from bottom to top. The insulation layer is PVC board insulation layer 9, between PVC boards The gap is double-layered and sealed with transparent tape;

[0071] S2. Shielding room frame construction: use the corner keel 1 to build a rectangular shielding room frame structure. The cross section of the corner keel 1 is an "L"-shaped structure. The structure is set on the PVC board insulation layer 9 on the ground, and the corner keel 1 is spliced at a 45° bevel angle at the top corner of the frame structure of the shieldin...

Embodiment 3

[0077] Such as Figure 7-9 As shown, a shielding module 2 for building the modular shielding room in Embodiment 1 is provided, including a shielding plate 21, a profile 22 and a bead 23 for fixing the shielding plate, and the profile 22 and the bead 23 are used together.

[0078] The shielding board 21 includes a paint-free board 210 and an electromagnetic shielding layer 211 mounted on a first surface of the paint-free board 210 .

[0079] The profile 22 has a flat surface 220 in contact with the electromagnetic shielding layer 211, the center of the flat surface is provided with a first groove 221 penetrating through the profile 22, and the connection between the first groove 221 and the flat surface is provided with a zigzag convex structure , the protrusion structure includes a first protrusion 222 vertically protruding from the flat surface, and also includes a second protrusion 223 extending into the groove, and there is a connecting portion 224 between the first protrus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com