A high-power circulator and its anti-microdischarge design method

A circulator and high-power technology, applied in the field of circulator and its anti-micro-discharge design, can solve the problems of increased loss and great influence on the electrical performance of microwave components, achieve small structure size, avoid low-pressure discharge, and micro-discharge thresholds The effect of power increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Example 1: High-power Y-junction circulator and its anti-micro-discharge design method

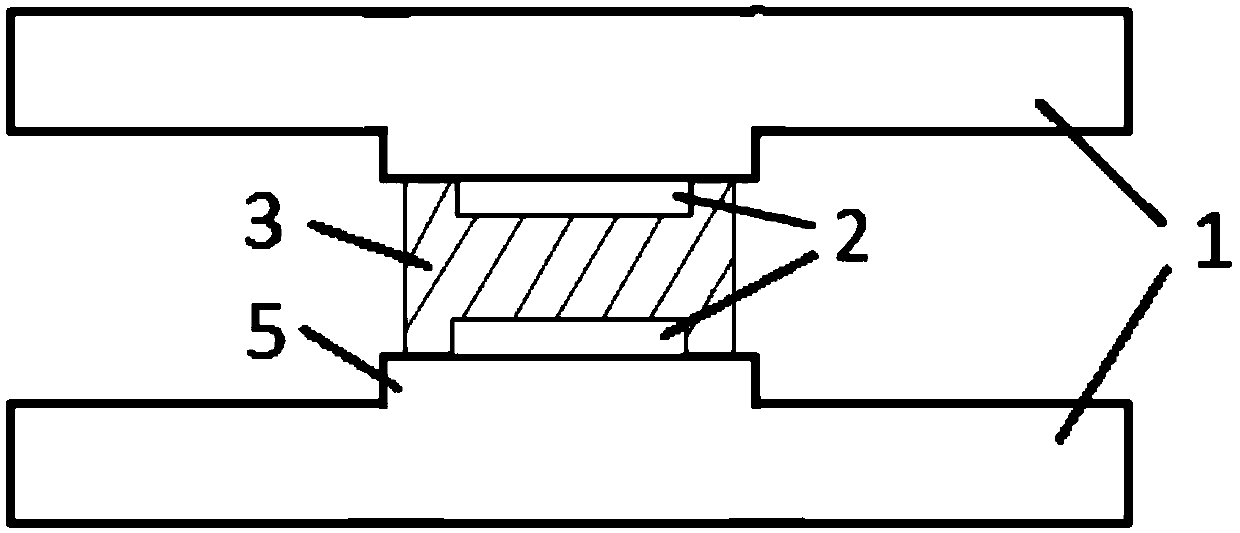

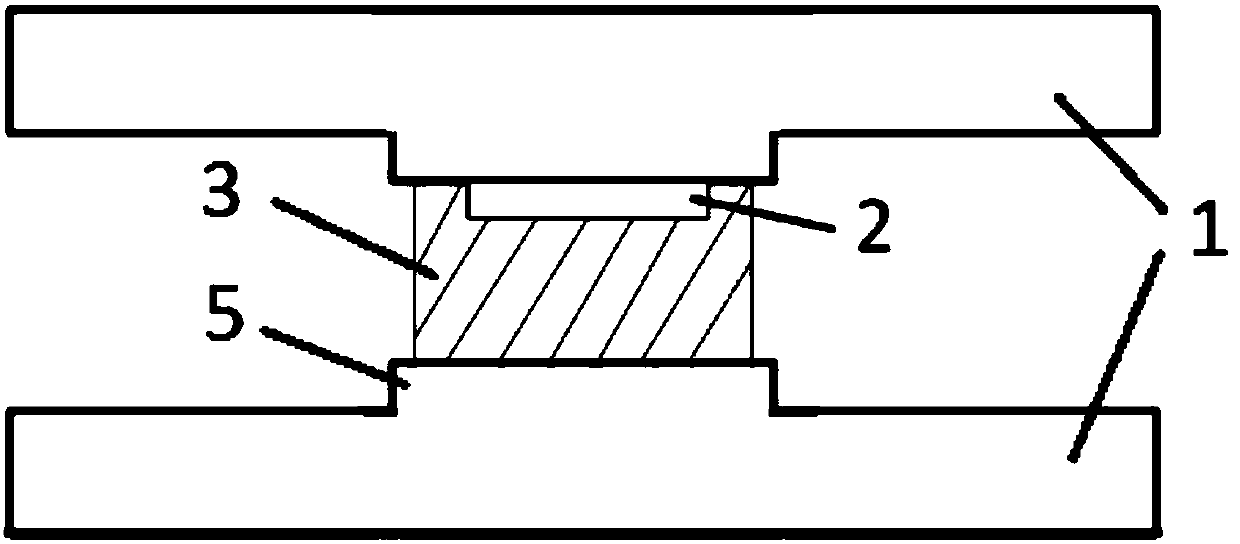

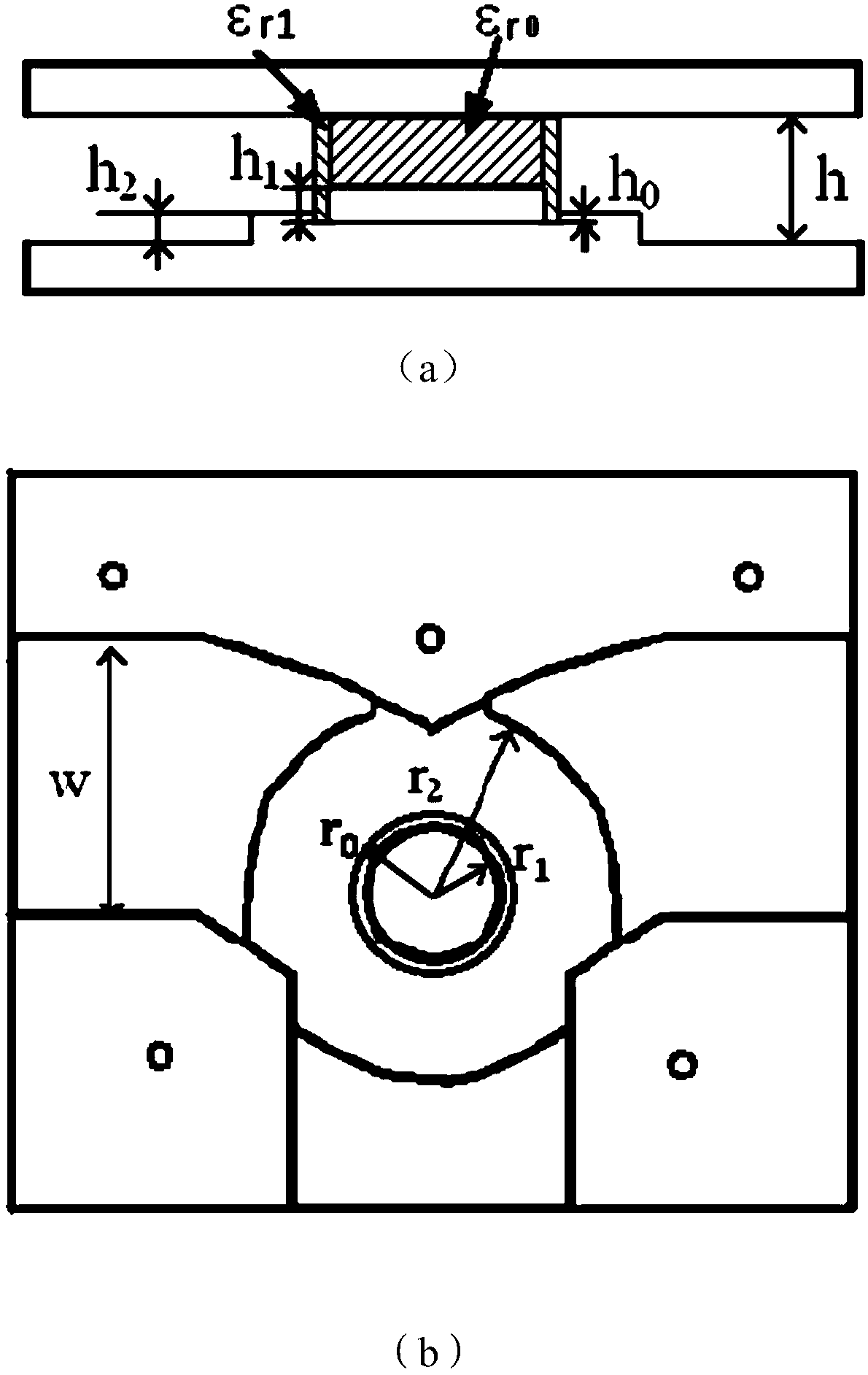

[0047] Such as Figure 5 As shown, the high-power circulator includes a metal cavity 1, a ferrite gyromagnetic substrate 2, and a dielectric card slot 3. A metal matching table 5 and a positioning groove 4 are processed on the metal cavity 1, wherein the ferrite The body gyromagnetic substrate 2 is located in the media card slot 3. The media card slot 3 clamps the ferrite gyromagnetic substrate 2 in the metal cavity 1; the upper cover of the metal cavity 1 is installed on the base, and the upper cover is connected with A cavity is formed between the bases. The cavity includes a central area loaded with ferrite gyromagnetic substrate 2 and three ports. The three ports are respectively connected to external circuits. When a certain frequency of electromagnetic waves is incident on one port, the electromagnetic waves It is output by the next port of the loop, and has a certain degree of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com