Efficient full-time double-layer-flowing pollution discharging device

A sewage device and double-layer flow technology, applied in fish farming, application, animal husbandry, etc., can solve the problems of low flow rate of sewage pipes, low bottom sewage discharge efficiency, and incomplete sewage discharge, etc., and achieve short-term efficient sewage and sewage discharge Thorough and efficient results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

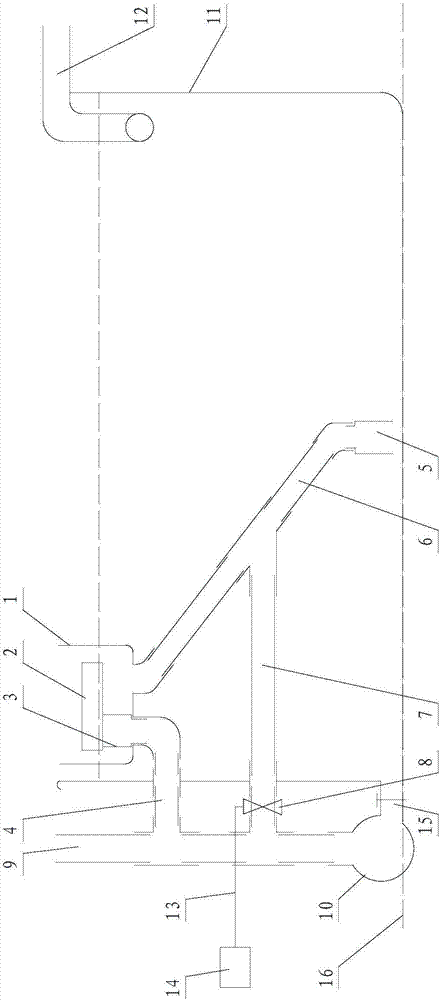

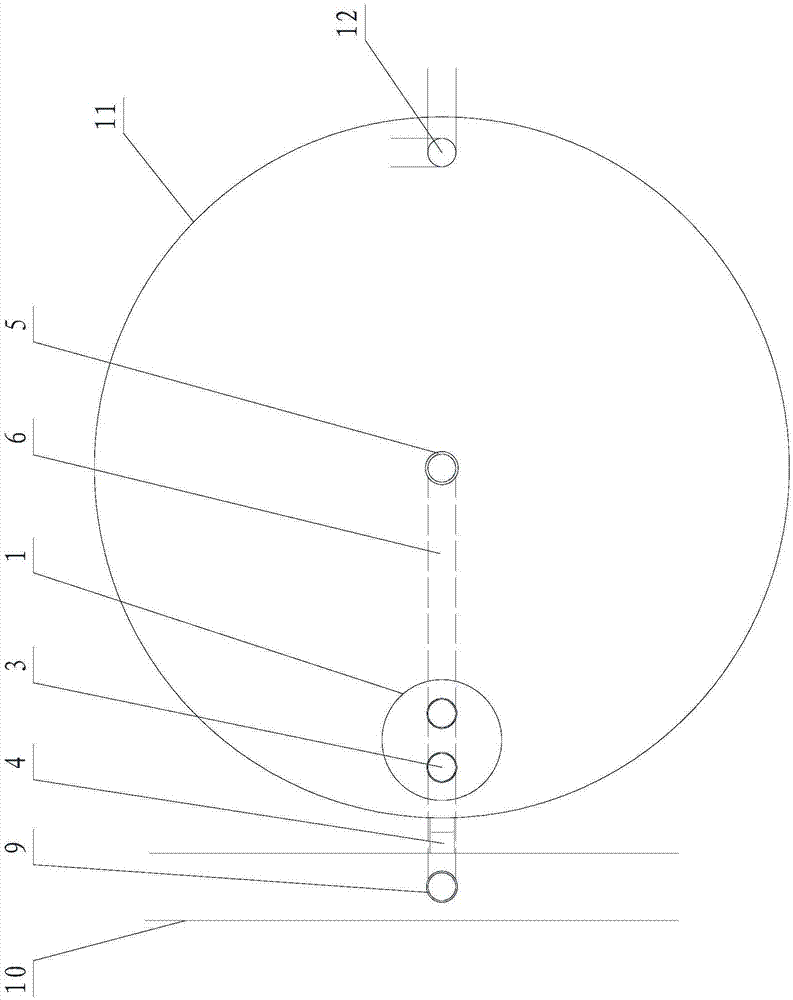

[0025] Such as figure 1 and figure 2 As shown, the main part of the sewage discharge device of the present invention is located inside the culture tank 11, and the main sewage pipe 10, the standpipe 9 and the electronic control part are located outside the culture tank 11, including a surface overflow sewage device for removing foam floating objects on the surface of the culture water body 1. The bottom surge sewage discharge device for removing the bottom sewage of the aquaculture water body and the variable flow adjustment device for high-speed sewage discharge. The surface overflow sewage discharge device includes a sewage collection tank 1, a water level adjustment pipe 3 and an upper sewage pipe 4. The bottom surge sewage discharge device It includes the bottom sewage suction pipe 5, the surge pipe 6, the sewage collection tank 1, the water level adjustment pipe 3 and the upper sewage pipe 4. The variable flow adjustment device includes the lower sewage pipe 7 connected ...

Embodiment 2

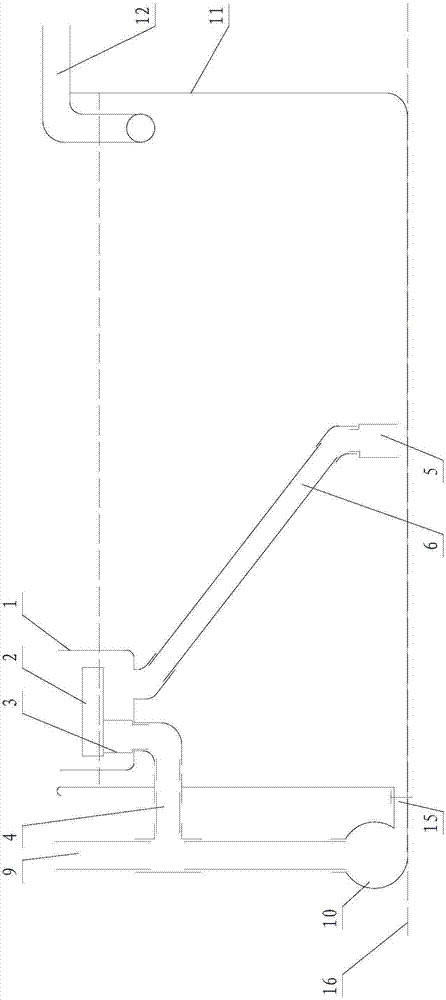

[0030] Such as image 3 As shown, the difference between the present embodiment and the first embodiment is: when the automatic sewage discharge control function is reduced in the first embodiment, the lower sewage pipe 7, the electric valve 8, the circuit 13 and the controller 14 can be removed. Except that the present embodiment does not have the automatic sewage discharge control function in the first embodiment, the implementation of the functions of other components is the same as that of the first embodiment.

Embodiment 3

[0032] Such as Figure 4 As shown, the present embodiment is suitable for the breeding ponds with bottom sewage pipes, and the difference with embodiment one is that the bottom sewage pipes 15 are pre-buried pipelines, which are pre-buried below the ground plane 16 where the cultivation tank 11 is placed; The bottom is a slope inclined downward from the outside to the inside, and the bottom sewage suction pipe 5 is located above the lowest point of the bottom of the breeding tank 11; The opening is connected, and the other end is connected with the main sewage pipe 10. A normally closed cover 17 is provided at the opening, and the cover 17 is only opened when the cultivation tank 11 needs to be drained. The realization of other functions is the same as that of the first embodiment. same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com