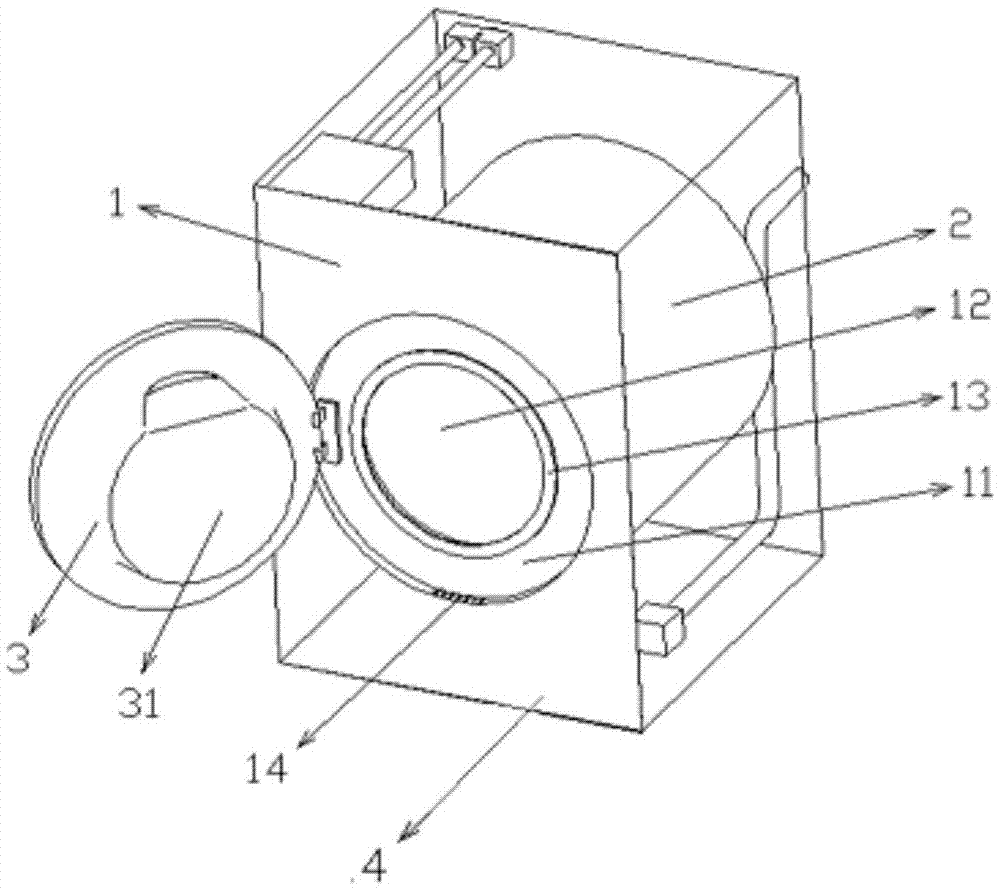

Roller washing machine and water leakage judgement method

A drum washing machine and washing machine technology, applied in the field of washing machines, can solve the problems of environmental pollution, shedding, and burning of electrical components around the washing machine, and achieve the effects of avoiding waste of water resources, avoiding washing water leakage, and shortening feedback time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] In the actual laundry process, the water leakage of the drum washing machine can be divided into water leakage in the water intake stage and water leakage in the washing / rinsing stage according to the washing program stage. This embodiment provides a water leakage judging method and water leakage countermeasures of the drum washing machine of the present invention during the water inflow stage.

[0054] Firstly, when doing laundry, the washing machine starts to take in water, and the water level in the washing tub 2 rises, and when the water level rises to the preset washing water level of the washing machine, it stops the water inflow and starts washing. The reason for the water leakage when entering the water is that there is a gap between the sealing ring 13 and the observation window 31, or the sealing ring is damaged, and when the water leakage gap caused by the above reasons is below the preset maximum water level of the washing machine, when the water is entering ...

Embodiment 2

[0080] Such as Figure 5 As shown, this embodiment provides a water leakage judgment method and water leakage countermeasures of the drum washing machine of the present invention in the washing / rinsing phase.

[0081] In the washing / rinsing stage, the reason for the water leakage is that the water leakage gap between the sealing ring 13 and the observation window 31 is above the preset maximum washing water level. As the washing drum rotates, the washing water is stirred up and down. leakage.

[0082] Further, the water leakage of the washing machine can be divided into slight water leakage and serious water leakage according to the amount of water leakage. The method for judging water leakage in the washing / rinsing stage and the countermeasures for water leakage provided in Embodiment 2 of the present invention are the same as the method for judging water leakage in the water intake stage provided in Embodiment 1. Compared with the countermeasures against water leakage, step...

Embodiment 3

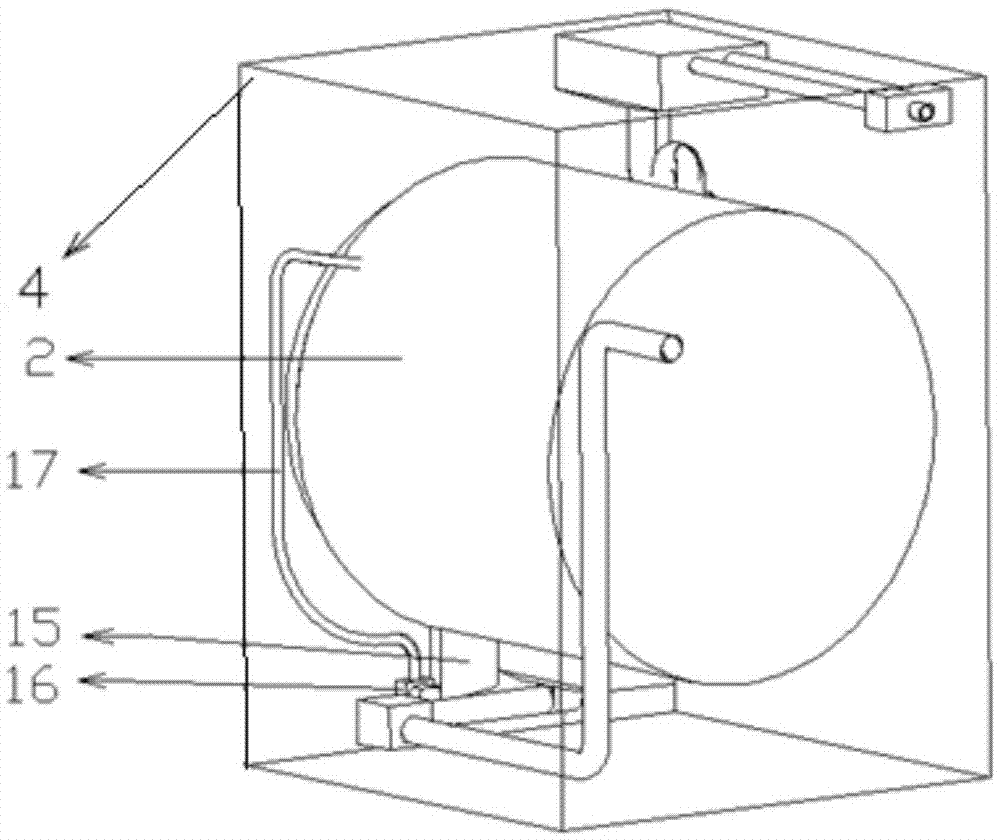

[0090] The drainage mechanism in this embodiment communicates with an external drainage pipeline (not shown).

[0091] When washing clothes, when the washing water leaks, the water receiving box 15 receives the washing water leaking from the leaking hole. Further, the water level detection device detects that the water level in the water receiving box is H>0, and sends out a water leakage information. At this time, the water leakage information According to the first water leakage information, the controller controls the drainage mechanism to start to discharge the leakage water received by the water receiving box 15 through the external drainage pipeline, avoiding the potential safety hazards of electric leakage and electric shock.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com