Electric steamer and steam control device and method thereof

A technology of a control device and an electric steamer, which is applied to steam cooking utensils, baking, cooking utensils, etc., can solve the problems of single detection result and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

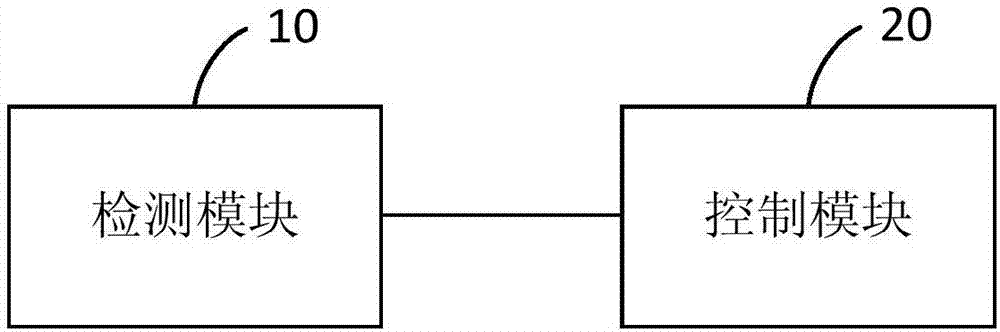

[0037] figure 1 Shown is a schematic structural view of the steam control device of the electric steamer provided in Embodiment 1 of the present invention. The specific structure of the steam control device of the electric steamer is as follows:

[0038] The detection module 10 is used to detect the pressure of the water in the water tank of the electric steamer in real time or regularly, and generate and output the pressure electric signal;

[0039] The control module 20 is electrically connected with the detection module 10, and is used for receiving the electric pressure signal, and judging the water volume in the water tank according to the electric pressure signal.

[0040] The working principle of the steam control device of the electric steamer is as follows: the detection module 10 detects the pressure of water in the water tank of the electric steamer in real time or regularly, generates and outputs an electric pressure signal. According to the formula:

[0041] P=ρ...

Embodiment 2

[0050] On the basis of the above-mentioned embodiments, the control module preferably can determine the amount of change in the water volume in the water tank within a required period of time. For example at t 1 At time, the volume of water in the tank is V 1 , after the work unit time interval, at t 2 At time, the volume of water in the tank is V 2 , the amount of water change is ΔV=V 1 -V 2 .

[0051] On the basis of the above technical solutions, the steam control device of the electric steamer preferably further adds a steam generator. Correspondingly, the control module is also used to control the amount of water flowing into the steam generator through the variation of the water amount in the water tank to control the amount of steam in the electric steamer.

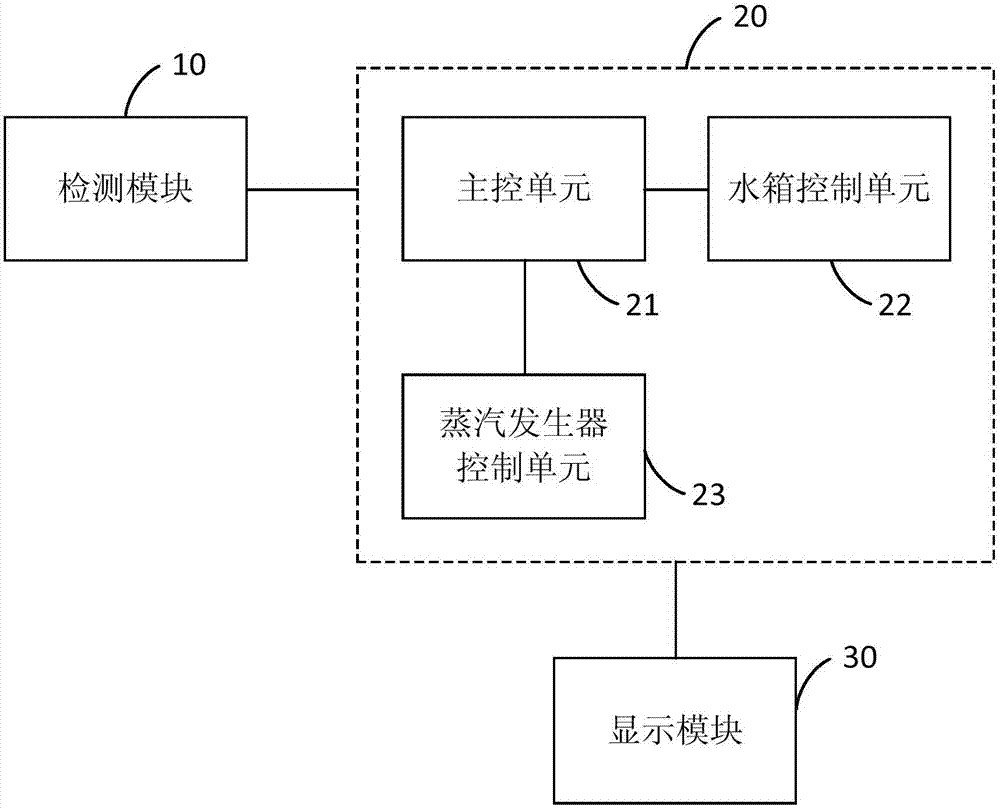

[0052] Specifically, see figure 2 , the control module 20 preferably includes:

[0053] The main control unit 21 is used to generate water intake information and steam generation information according to t...

Embodiment 3

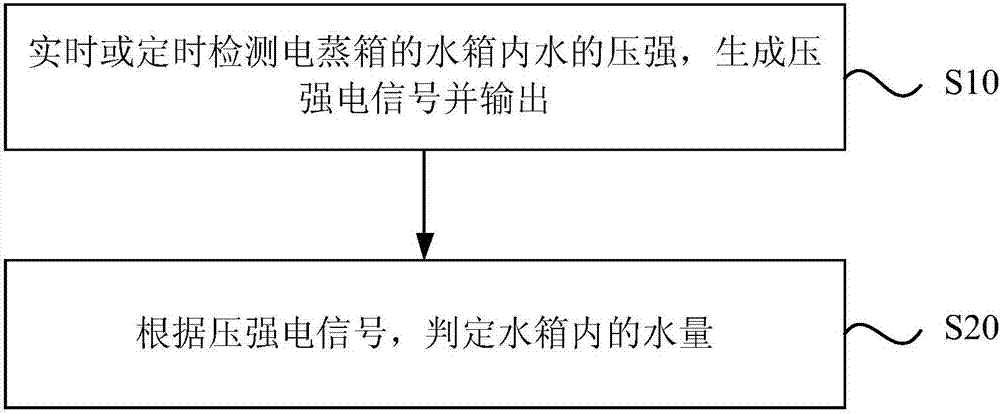

[0071] image 3 It is a flow chart of the steam control method of the electric steamer provided in Embodiment 3 of the present invention. The method can be executed by the steam control device of the electric steamer, and specifically includes the following steps:

[0072] Step 10, real-time or regular detection of the pressure of the water in the water tank of the electric steamer, generating and outputting a pressure electric signal;

[0073] Step 20, determine the water volume in the water tank according to the pressure electric signal.

[0074] On the basis of each of the above technical solutions, after judging the water volume in the water tank, it also includes: judging the amount of change in the water volume in the water tank within the required time length.

[0075] After determining the amount of water change in the water tank within the required time length, the method further includes: controlling the amount of water flowing into the steam generator according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com