Loose tube, loose tube type optical fiber cable, single-core separation method of loose tube optical fiber ribbon, method of manufacturing loose tube, and method of gathering multiple optical fibers

A technology of multiple optical fibers and optical fiber ribbons, which is applied in the field of loose tubes and can solve the problems of large diameter of loose tubes and contact of optical fiber ribbons.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

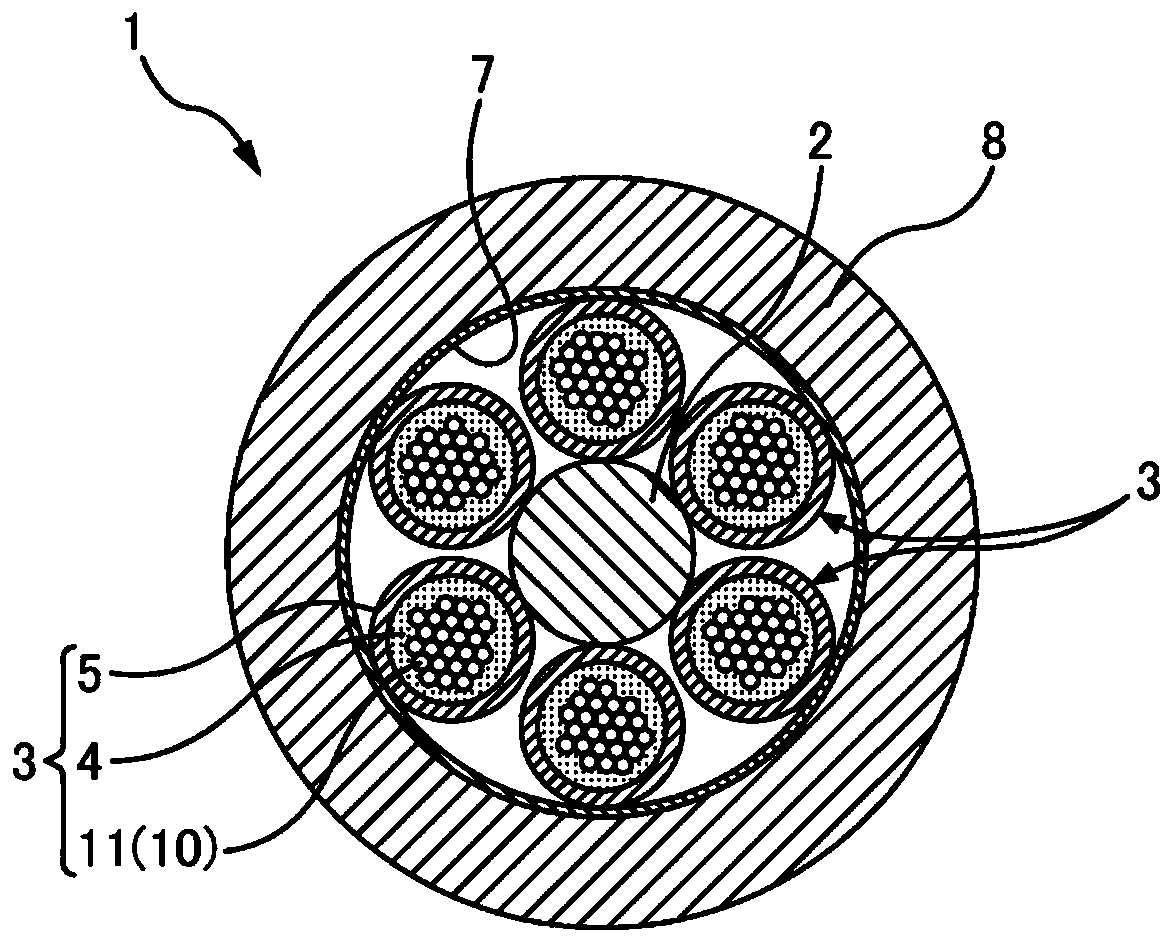

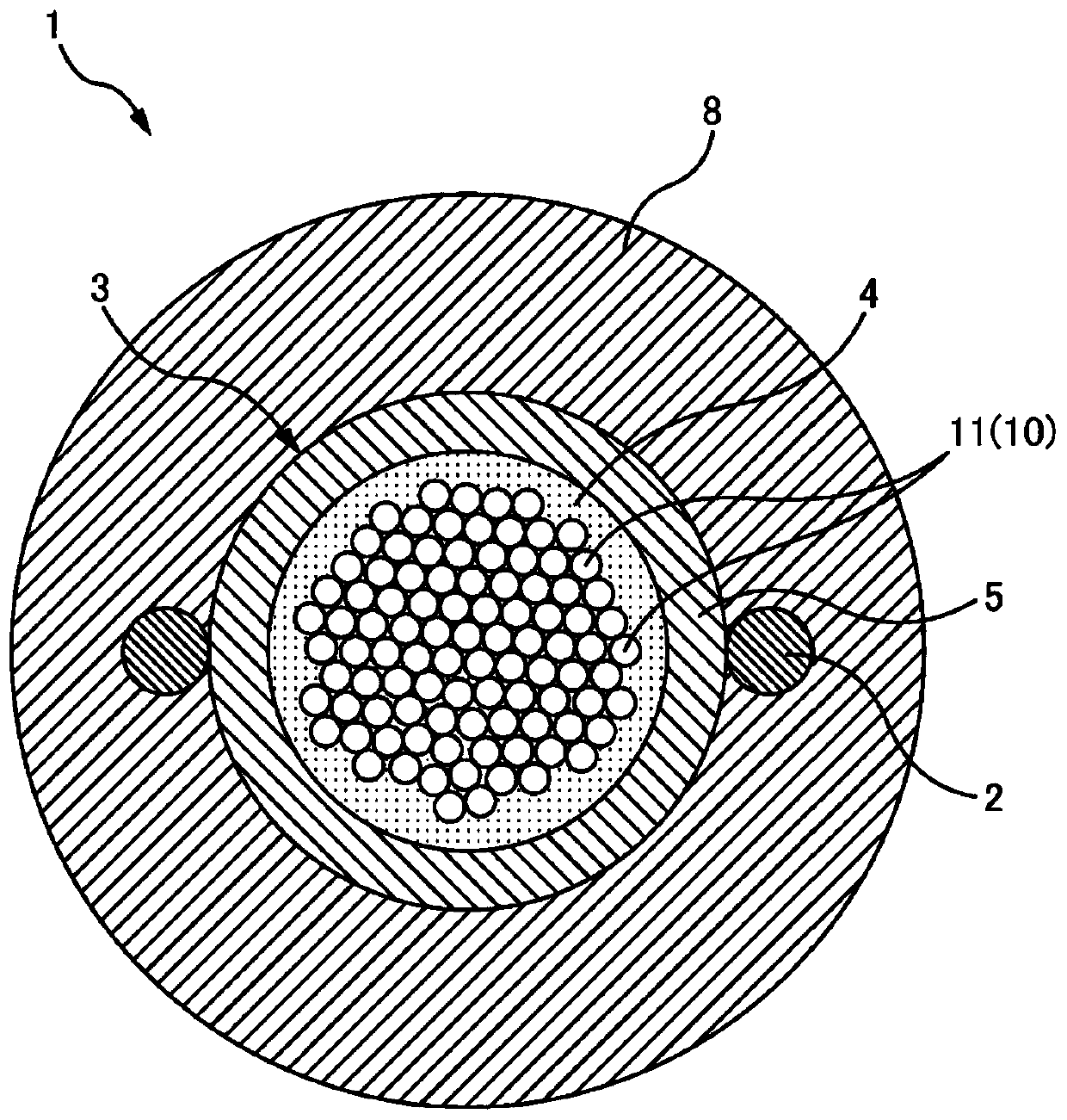

[0022] At least the following matters will be clarified from the contents described in the specification and drawings described later.

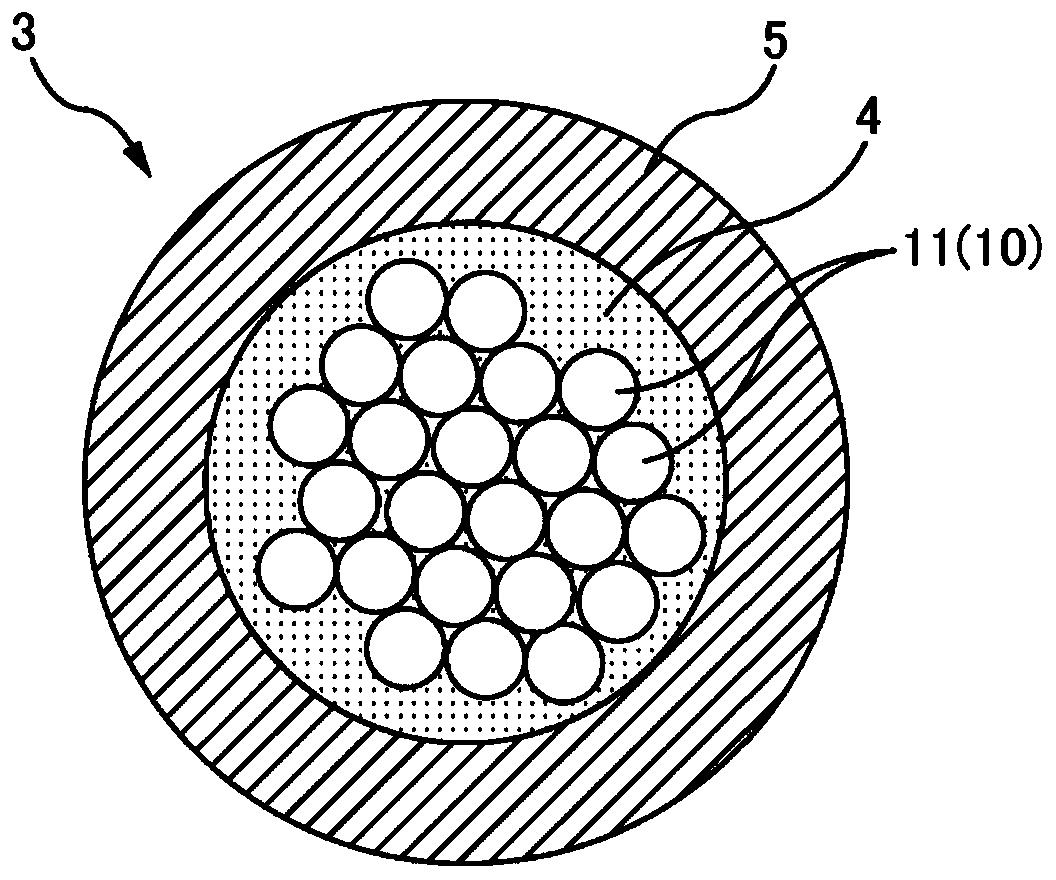

[0023] It is clarified that a loose tube is provided with a plurality of optical fibers and a sleeve for accommodating the plurality of optical fibers together with a filling material, wherein the plurality of optical fibers are discontinuously arranged with adjacent optical fibers The connection part of the connection is composed of a discontinuous fixed optical fiber ribbon, and the discontinuous fixed optical fiber ribbon is arranged in the sleeve in a state where the plurality of optical fibers constituting the discontinuous fixed optical fiber ribbon are bundled. inside the tube. Accordingly, it is possible to reduce the diameter of the loose tube having the optical fiber ribbon.

[0024] Preferably, the discontinuously fixed optical fiber ribbon is twisted so that the plurality of optical fibers constituting the discontinuously fixed o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap