A contact-type temperature-measurable plate shape detection device

A detection device and contact technology, applied in the direction of length measuring device, metal rolling, metal processing equipment, etc., can solve the problems of increasing the difficulty of strip steel temperature detection, large measurement error, difficult installation and debugging, etc., to achieve weakening heat conduction effect and thermal stress fluctuations, effective shape error temperature compensation, avoidance of effects of elastic creep behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

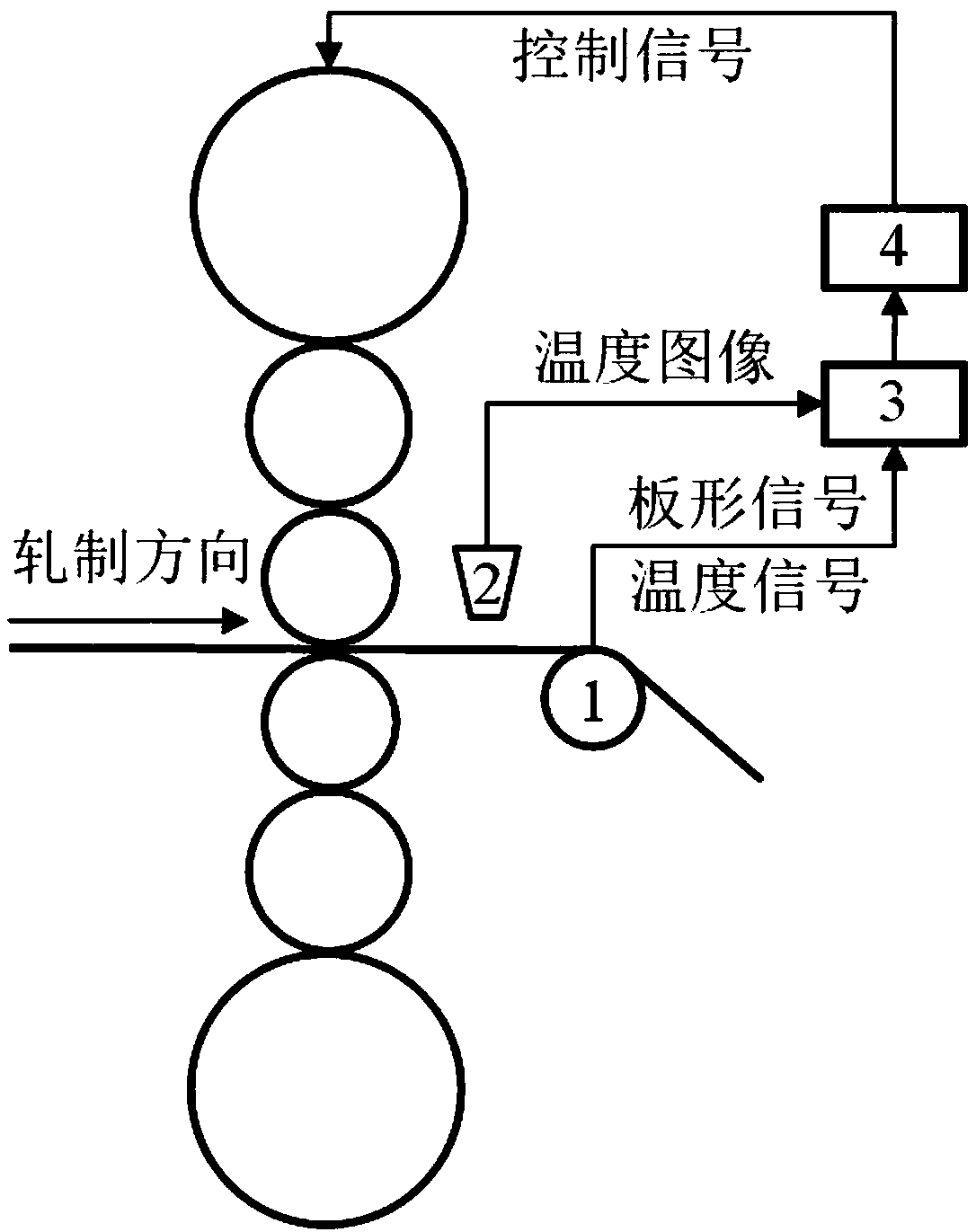

[0021] A contact-type temperature-measurable plate shape detection device of the present invention, figure 1 It is an embodiment of the present invention—the flow chart of on-line shape and instantaneous temperature detection of cold-rolled strip steel. The detection device includes a temperature-measurable shape detection roller 1, a thermal imager 2 and a shape measurement and control system 3; the temperature-measurable shape detection roller 1 can provide online shape signals and transient temperature signals at the same time; The thermal imager 2 is used to detect and provide the temperature field image of the cold-rolled strip; the flatness measurement and control system 3 is used to receive the flatness signal and the temperature signal, and perform signal processing and synchronous calculation, and real-time monitoring of the online stri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com