A laboratory-used automatic water replenishment flotation machine and its method for flotation

A laboratory, water flotation machine technology, applied in flotation, non-electric variable control, liquid level control and other directions, can solve the problems of low accuracy and repeatability of flotation indicators, and achieve the effect of avoiding manual misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

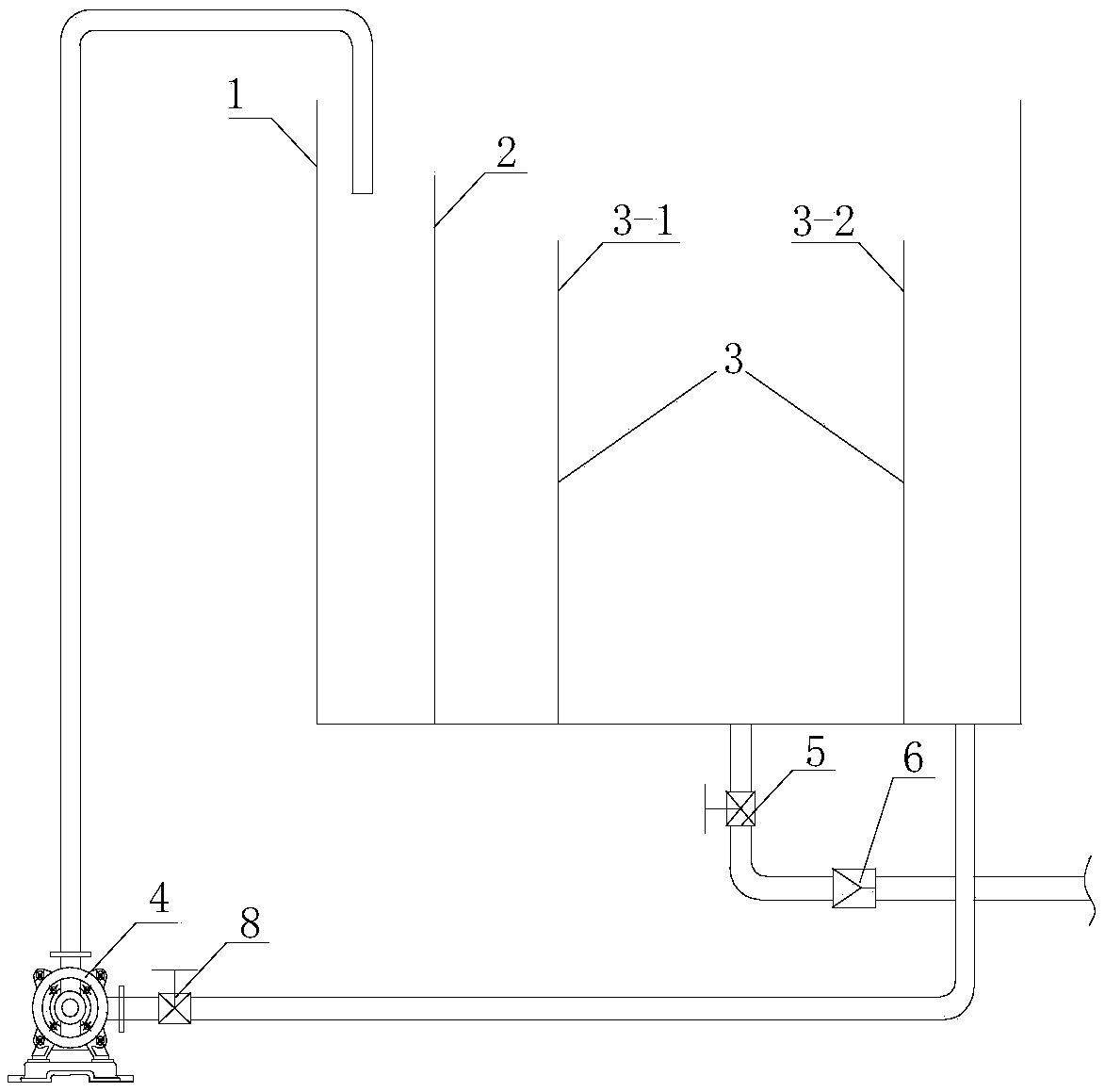

[0025] Specific embodiment one: present embodiment is a kind of automatic water replenishment flotation machine for laboratory, and it is made up of automatic water replenishment system, PLC control system and laboratory small flotation machine 11,

[0026] The automatic replenishment system includes a square tank 1, a steady flow plate 2, two constant liquid level plates 3, a water pump 4, a valve 5, a one-way valve 6, a water pump valve 8 and a flotation tank valve 9; The liquid level plate 3 is successively an inlet constant liquid level plate 3-1 and an overflow constant liquid level plate 3-2;

[0027] The steady flow plate 2, the water inlet constant liquid level plate 3-1 and the overflow constant liquid level plate 3-2 are arranged in parallel in the square tank 1 in sequence, and the square tank 1 is divided into four areas, respectively for the water inlet Area, steady flow area, constant liquid level replenishment area and overflow return water area, in which the wa...

specific Embodiment approach 2

[0033] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the valve 5 is arranged on the pipeline between the one-way valve 6 and the constant liquid level replenishment area. Others are the same as the first embodiment.

specific Embodiment approach 3

[0034] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that: the bottom of the steady flow plate 2 is provided with several steady flow round holes 7, and the water inlet area and the The steady flow area is connected. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com