Frequency converter

A frequency converter and radiator technology, applied in the field of frequency converters, can solve the problems of inconvenient disassembly, inconvenience, and difficult maintenance, and achieve the effect of easy replacement and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

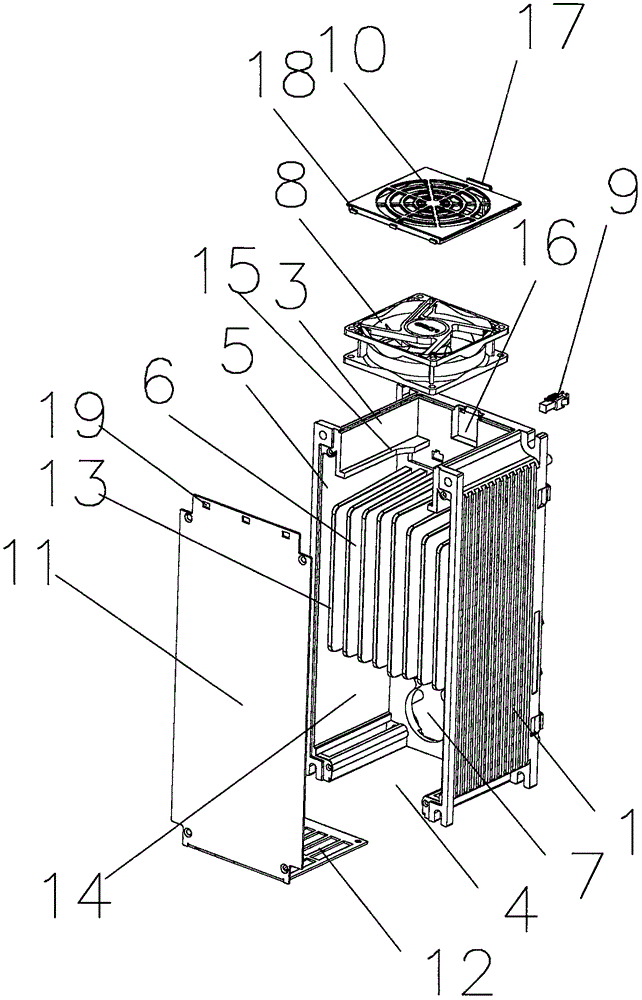

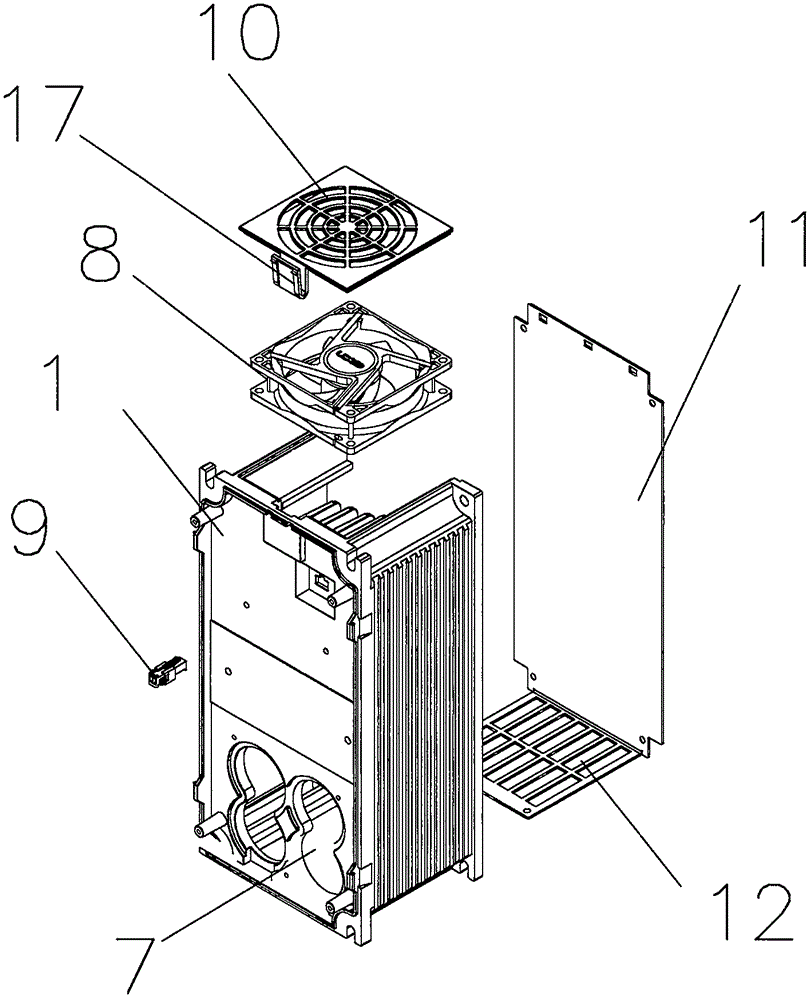

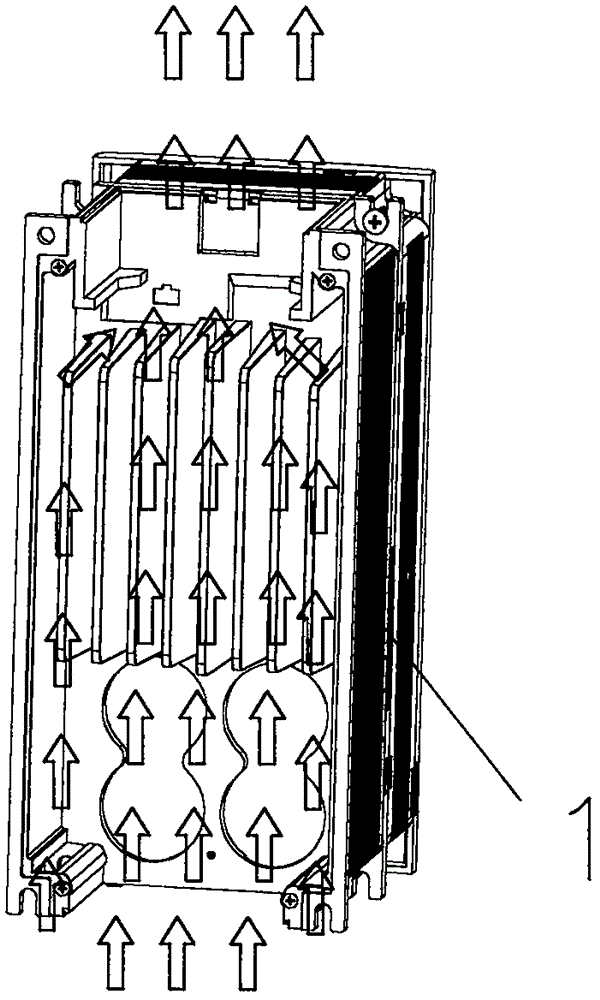

[0032] exist figure 1 , figure 2 , image 3 In the illustrated embodiment, a heat dissipation system for a frequency converter includes:

[0033] The aluminum die-casting heat sink 1 is fastened with the inverter main body 2 for heat dissipation; the aluminum die-casting heat sink 1 is in a tank structure and is provided with an upper notch 3, a lower notch 4 and a back notch 5, and the aluminum die-casting heat sink 1 The inside of the tank is provided with a number of heat dissipation air ducts 6 arranged along the direction from the lower notch 4 to the upward notch 3; the aluminum die-casting radiator 1 is provided with mounting holes 7 for internal components of the frequency converter, and the mounting holes 7 for internal components of the frequency converter communicate with the cooling air Road 6;

[0034] The fan 8 is connected to the inside of the upper notch 3 of the aluminum cast radiator 1 through the quick interface 9 and is arranged facing the cooling air d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com