Method for detecting the position of oblique holes in parts

A detection method and technology for parts, which are applied to measurement devices, optical devices, instruments, etc., can solve the problems of long production cycle, high cost, and high calibration technical requirements, and achieve the effects of cost saving, design reduction, and high detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

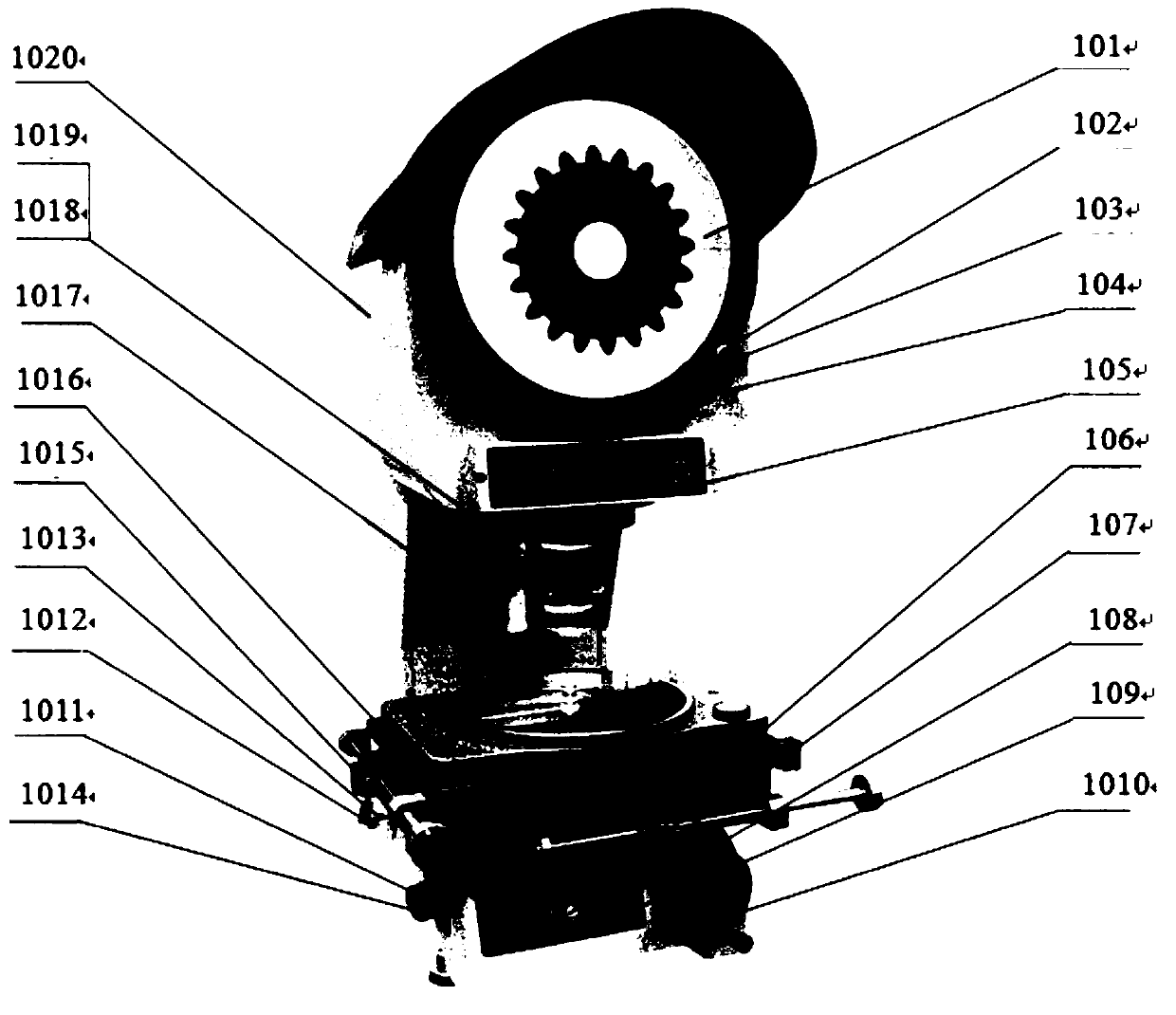

[0051] Such as Figure 1 to Figure 8 As shown, a method for detecting the position of oblique holes in parts includes the following detection steps:

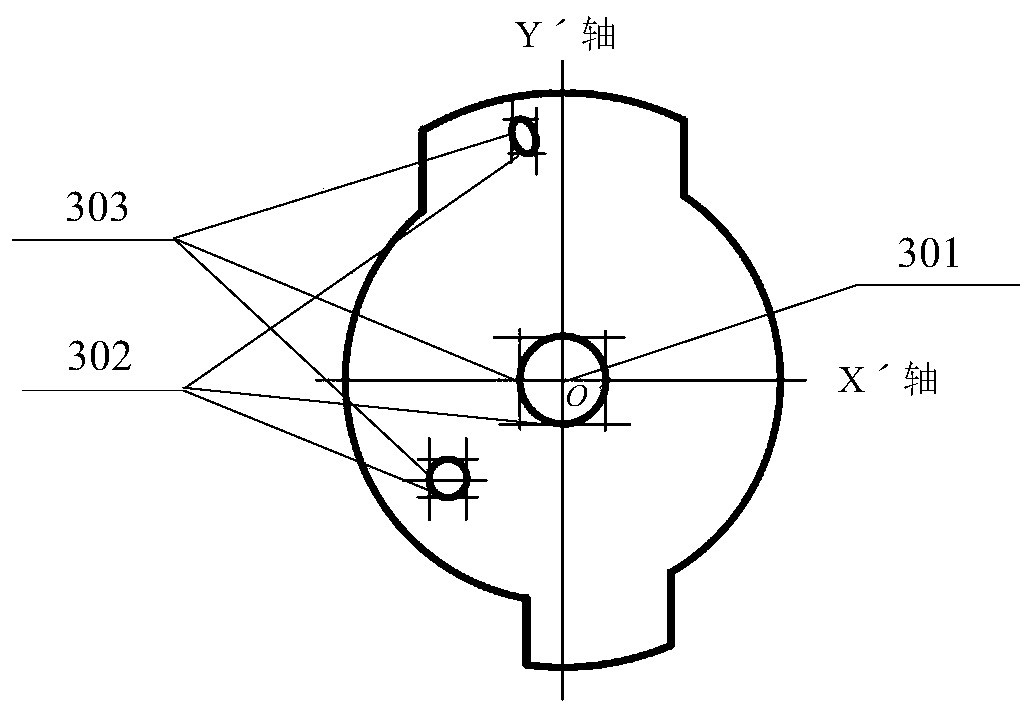

[0052] S1. Using a measuring projector to establish a detection coordinate system (Xˊ, Yˊ) on the projection screen based on the center hole A of the component; S1 specifically includes the following steps:

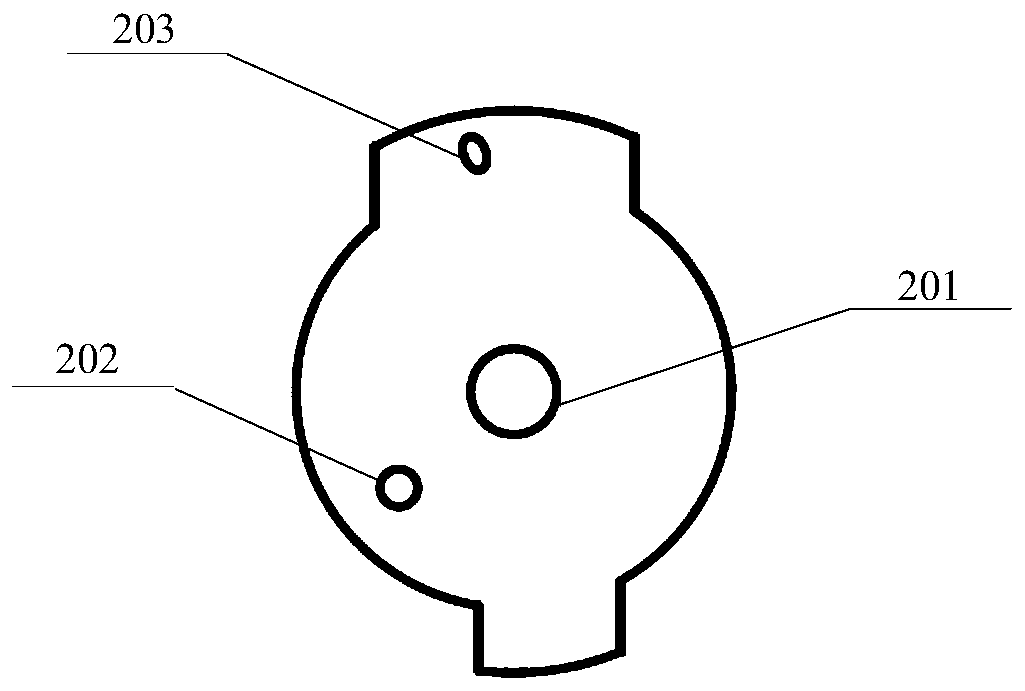

[0053] S11. Place the part with the side of the oblique hole facing up on the center of the workbench 1016 of the measuring projector, turn on the power switch 107 of the measuring projector, turn the lifting hand wheel 1010 of the projection box to adjust the focus to the upper surface of the part, Until the central hole A201 of the component is clearly projected on the projection screen 101 of the measuring projector.

[0054] S12. Rotate the horizontal axis and vertical axis handwheels on the measuring projector workbench 1016 respectively to confirm that the contours of the central hole A201, positioning hole B202 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com