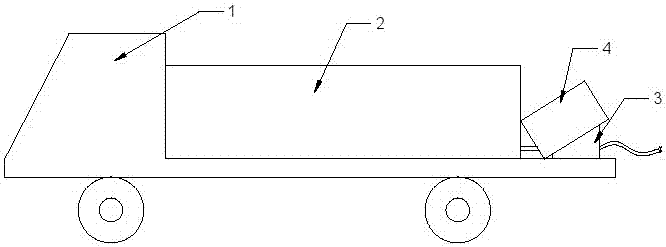

High-low-pressure hybrid watering cart

A sprinkler, high and low pressure technology, applied in road cleaning, construction, cleaning methods, etc., can solve problems such as unit price as high as more than 500,000, shorten road cleaning time, high equipment cost, etc., achieve comprehensive cost savings, improve operation efficiency, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

[0029] To wash the same section of pedestrian pavement and roadside that has been cleaned for a long time, the traditional sprinkler and the sprinkler of this scheme are used for the operation. (Due to the long-term cleaning of the road surface, there is no equipment that is affected by the front or back operation)

[0030] The water tank capacity of the two types of sprinklers is 10T.

[0031] Using traditional sprinklers: put in 4 drivers and rinsing workers to work, each tank of water is used up in an average of 1.5 hours before filling the water pile, and the water needs to be added 4 times a day, each time adding water takes 0.5 hours, thus shortening the road surface cleaning Time; the chassis engine uses an average of 55-60 liters of fuel per day;

[0032] Sprinklers using this scheme: put in 3 drivers and washing workers for operation, and reduce the investment of 1 washing worker; each tank of water is used up in 15 hours on average, and can be used continuously for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com