Special precise and quick locating welding machine for disc-shaped parts

A technology of positioning welding and parts, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of not easy to fix, uneven welding seam, no good positioning, etc., to achieve welding automation, welding seam uniformity, welding Time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the present invention are described in detail below based on the drawings.

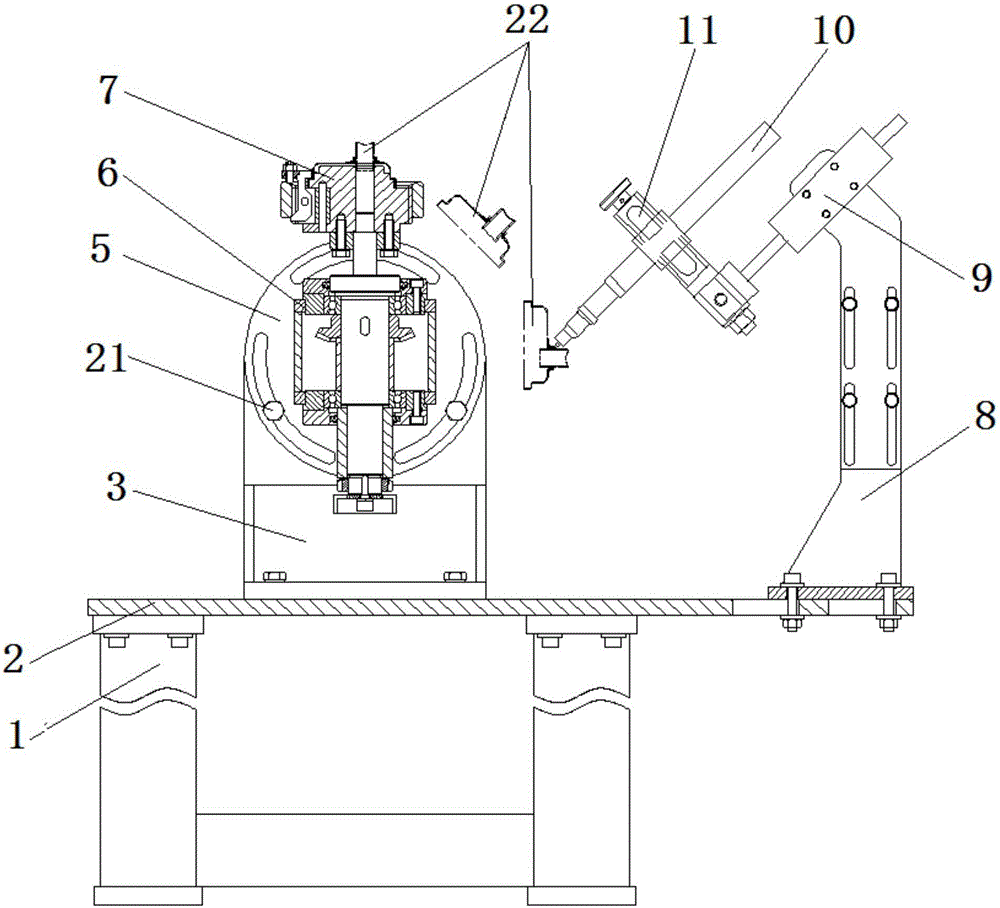

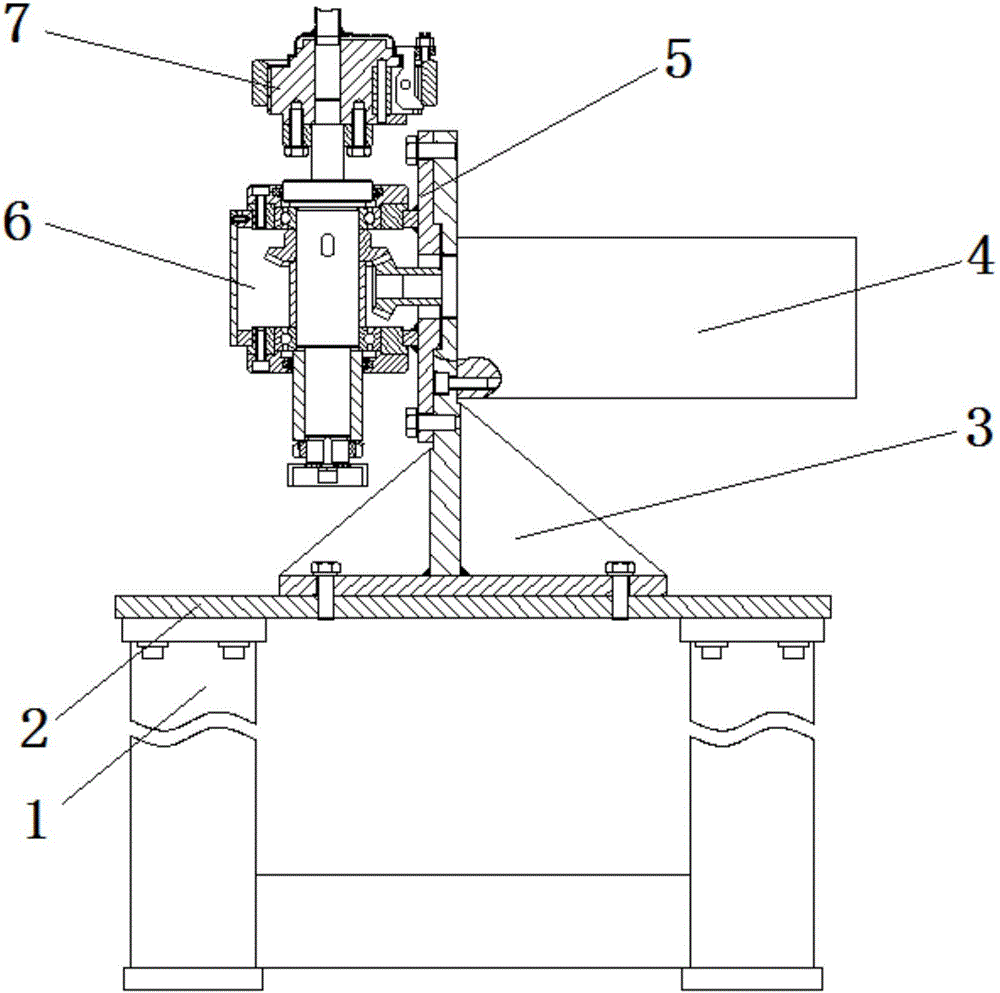

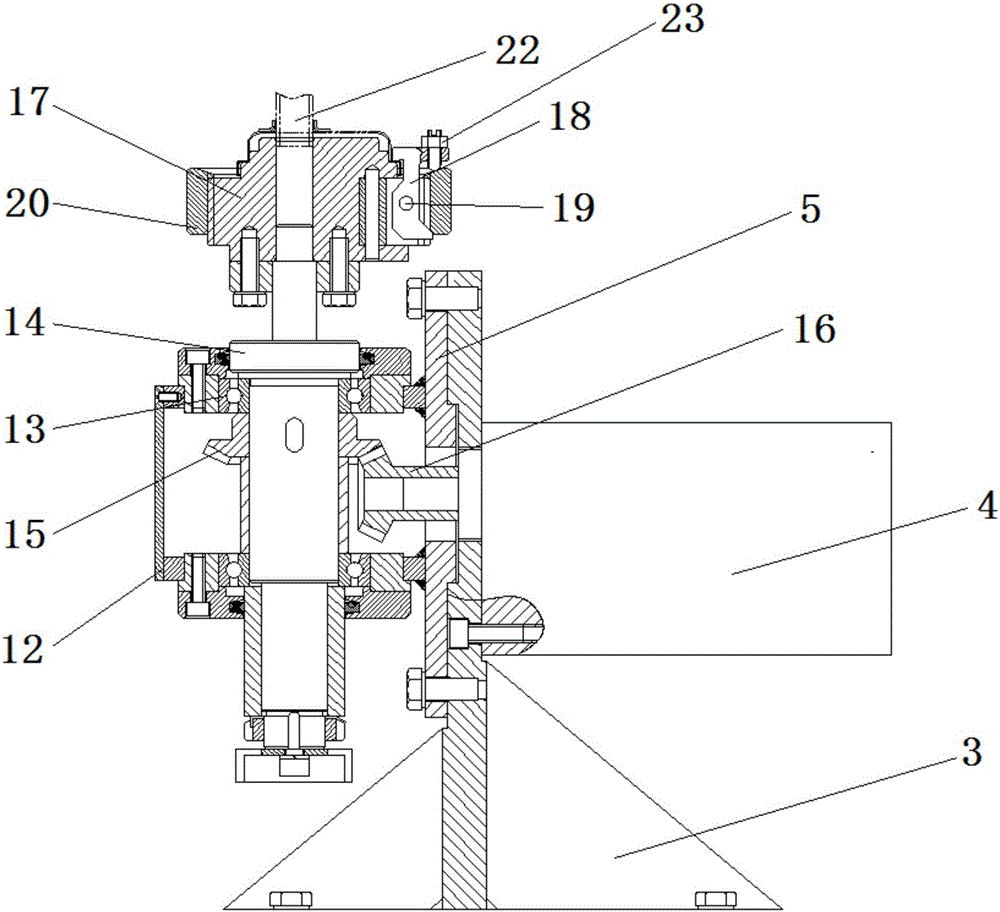

[0022] Such as Figure 1 to Figure 9 As shown, the precise and rapid positioning and welding machine for disc-shaped parts of the present invention includes a base 1, a support 3, a motor 4, a workpiece adjusting plate 5, a transmission mechanism 6, a workpiece fixing mechanism 7 and a welding gun mechanism;

[0023] The machine base 1 is provided with a machine base upper plate 2. The bracket 3 and the welding torch mechanism are installed on the machine base upper plate 2 side by side, the motor 4 and the workpiece adjustment plate 5 are fixedly installed on both sides of the bracket 3, and the transmission mechanism 6 Installed on the workpiece adjusting plate 5, the output end of the motor 4 is connected with the input end of the transmission mechanism 6, and the workpiece fixing mechanism 7 is installed on the output end of the transmission mechanism 6;

[0024] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com