Spine fixing assembly

A technology for fixing components and spine, applied in the field of spinal fixation components, can solve the problem of lack of bone barrier protection in the spinal dura mater, and achieve the effect of avoiding the adhesion between the dural sac and nerve roots and relieving pain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

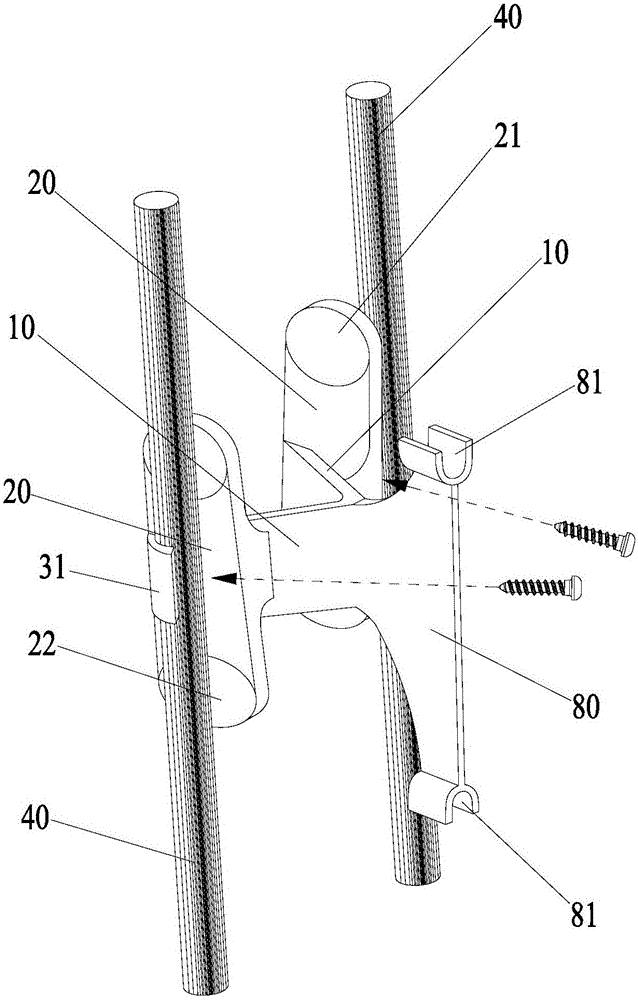

[0075] The design steps and manufacturing method of the spinal fixation assembly of Embodiment 1 are as follows:

[0076] 1. First, use the interactive medical image control system to establish the vertebral body segment (affected vertebral body) and the adjacent healthy physiological vertebral body segment of the patient's spinal disease based on the patient's CT or MRI and other medical three-dimensional tomographic scan data. 3D model;

[0077] 2. According to the plan formulated by the medical diagnosis, the part that is expected to be resected is removed from the three-dimensional model;

[0078] 3. Design spinal fixation components according to the need to fill the space of the occupied bone defect;

[0079] 4. When designing the spinal canal covering plate 10, enough space for the spinal canal should be reserved;

[0080] 5. The designed upper spinous process junction 81 should be in good contact with the lower edge of the spinous process of the upper adjacent healthy...

Embodiment 5

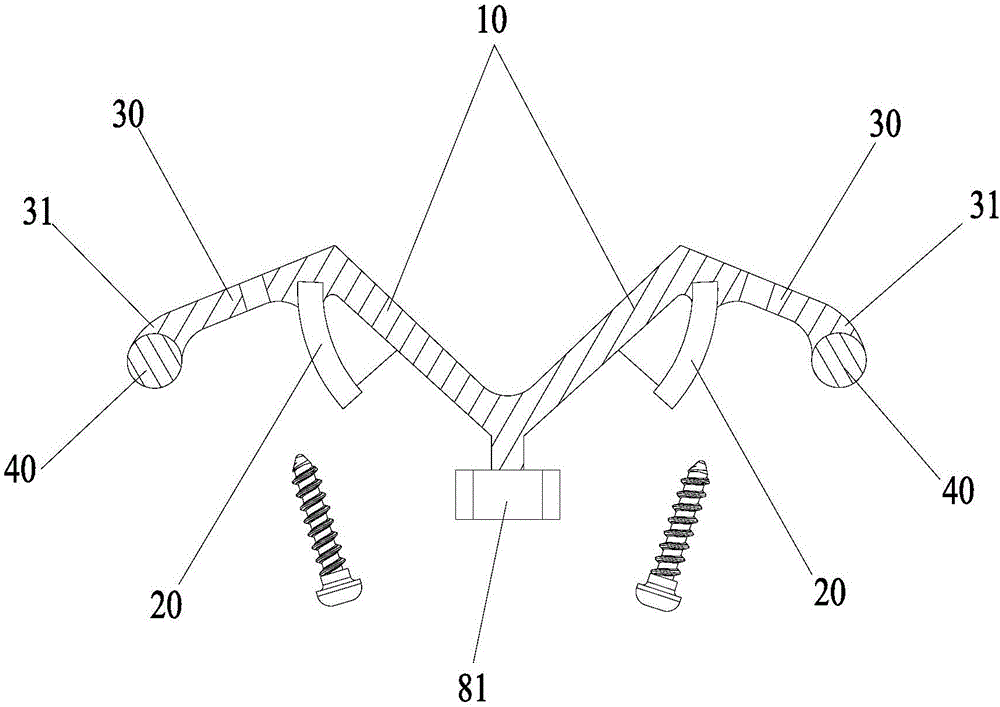

[0090] The design steps and manufacturing method of the spinal fixation assembly of Embodiment 5 are as follows:

[0091] 1. First, use the interactive medical image control system to establish a three-dimensional model of the affected vertebral body of the patient's spine and the adjacent healthy physiological vertebral body segments based on the patient's CT or MRI and other medical three-dimensional tomographic scanning data;

[0092] 2. According to the plan formulated by the medical diagnosis, the part that is expected to be resected is removed from the three-dimensional model;

[0093] 3. Design spinal fixation components according to the need to fill the space of the occupied bone defect;

[0094] 4. When designing the spinal canal covering plate 10, enough space for accommodating the spinal canal should be reserved;

[0095] 5. The designed first articular process junction should have good contact fit or fit with the inferior articular process of the upper adjacent he...

Embodiment 6

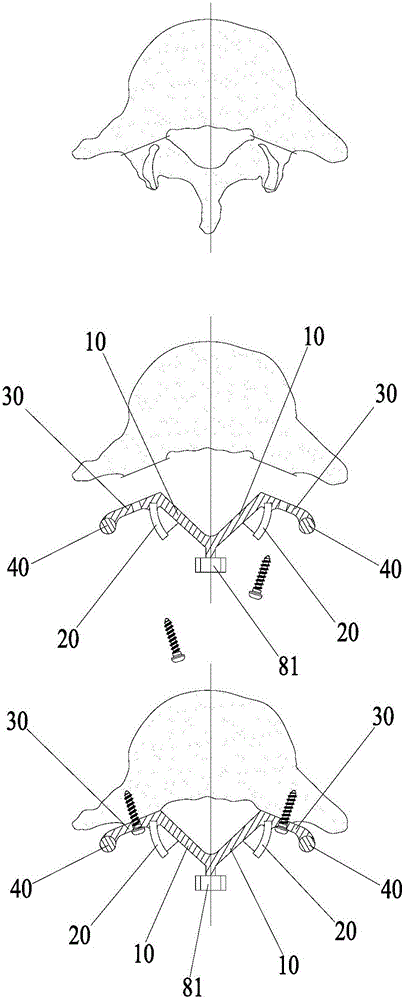

[0101] The design steps and manufacturing method of the spinal fixation assembly of Embodiment 6 are as follows:

[0102] 1. First, use the interactive medical image control system to establish a three-dimensional model of the affected vertebral body of the patient's spine and the adjacent healthy physiological vertebral body segments based on the patient's CT or MRI and other medical three-dimensional tomographic scan data;

[0103] 2. According to the plan formulated by the medical diagnosis, the part that is expected to be resected is removed from the three-dimensional model;

[0104] 3. Design spinal fixation components according to the need to fill the space of the occupied bone defect;

[0105] 4. When designing the spinal canal covering plate 10, enough space for accommodating the spinal canal should be reserved;

[0106] 5. The designed first articular process junction 21 should have good contact fit or fit with the inferior articular process of the adjacent healthy p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com