Oil-based drilling fluid and preparation method thereof

An oil-based drilling fluid and solution technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of oil-based drilling fluids polluting the environment and being difficult to degrade, achieving economical and efficient large-scale production, low toxicity, Low biotoxic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

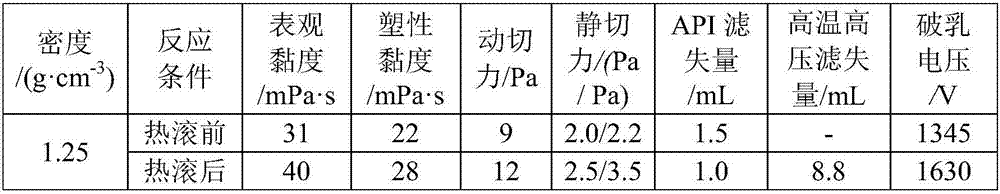

[0049] This embodiment provides a method for preparing low-toxic and environment-friendly oil-based drilling fluid, which includes the following steps:

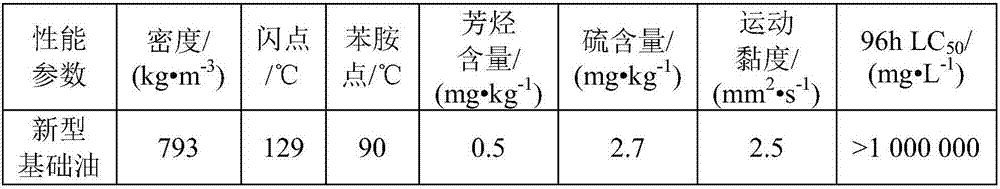

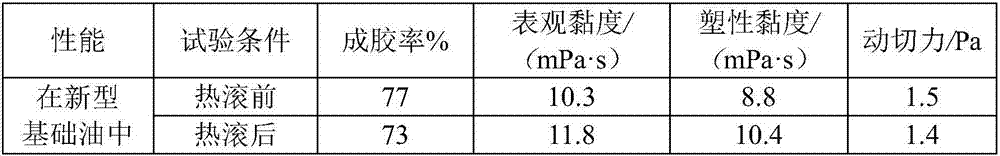

[0050] Step 1: Converting organic sulfides in crude oil into H through primary hydrocatalytic cracking 2 S, and convert most of the olefins in the crude oil into alkanes; then remove more mercaptans in the crude oil through secondary catalytic oxidation, further reduce the sulfur content, and obtain a new type of base oil for desulfurization and dearomatization, and its performance parameters are shown in Table 1. Show;

[0051] Step 2: Mix ethanol and water at a mass ratio of 1:10 to better disperse and dissolve montmorillonite and organic modifier, then add sodium montmorillonite to dissolve, and then octadecyltrimethylammonium chloride and cetyltrimethylammonium chloride are mixed at a mass ratio of 1:1 to obtain a long carbon chain quaternary ammonium salt cationic surfactant, and the long carbon chain quaternary ammoniu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com