A compressor stator blade with a large bending angle and a multi-section blade type connected in series at the root

A technology of stator blades and bending angles, which is applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as difficult engineering implementation, no self-adaptability, and limited working condition range, and achieves reduced performance benefits and improved performance. The effect of engineering application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

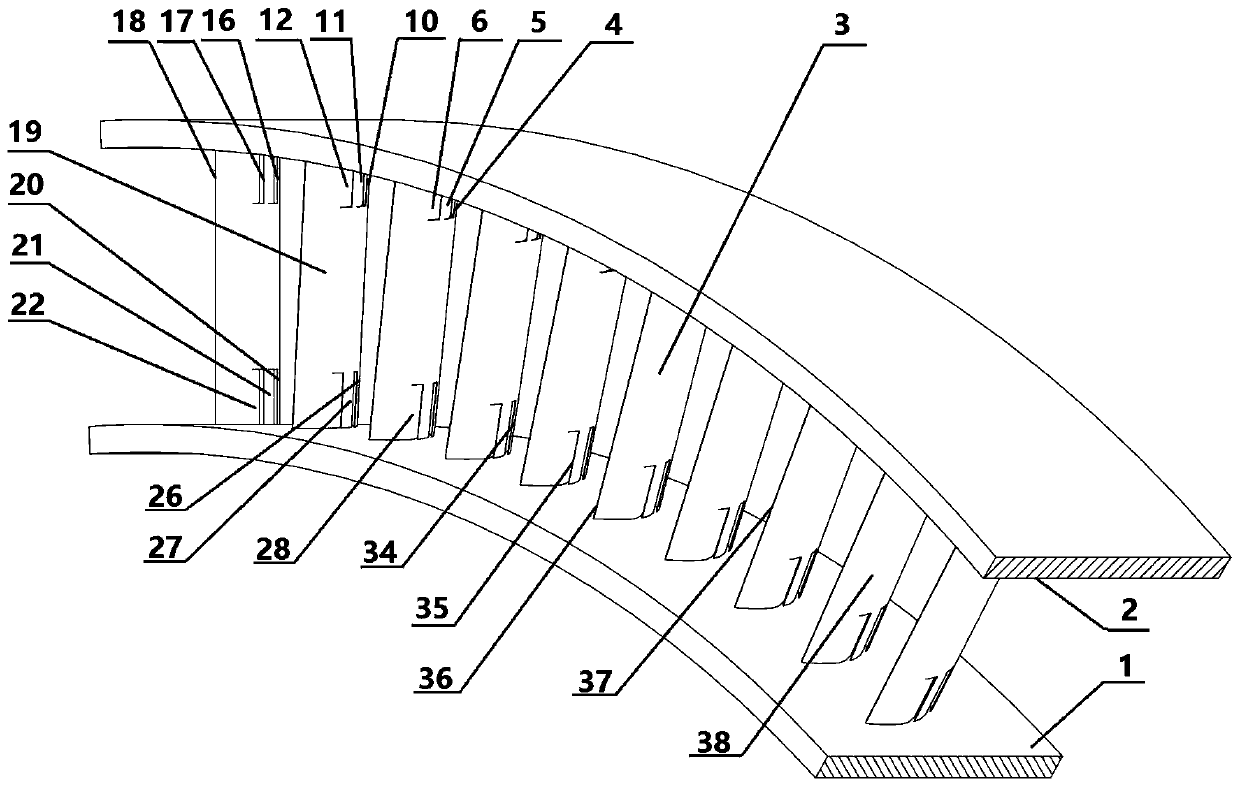

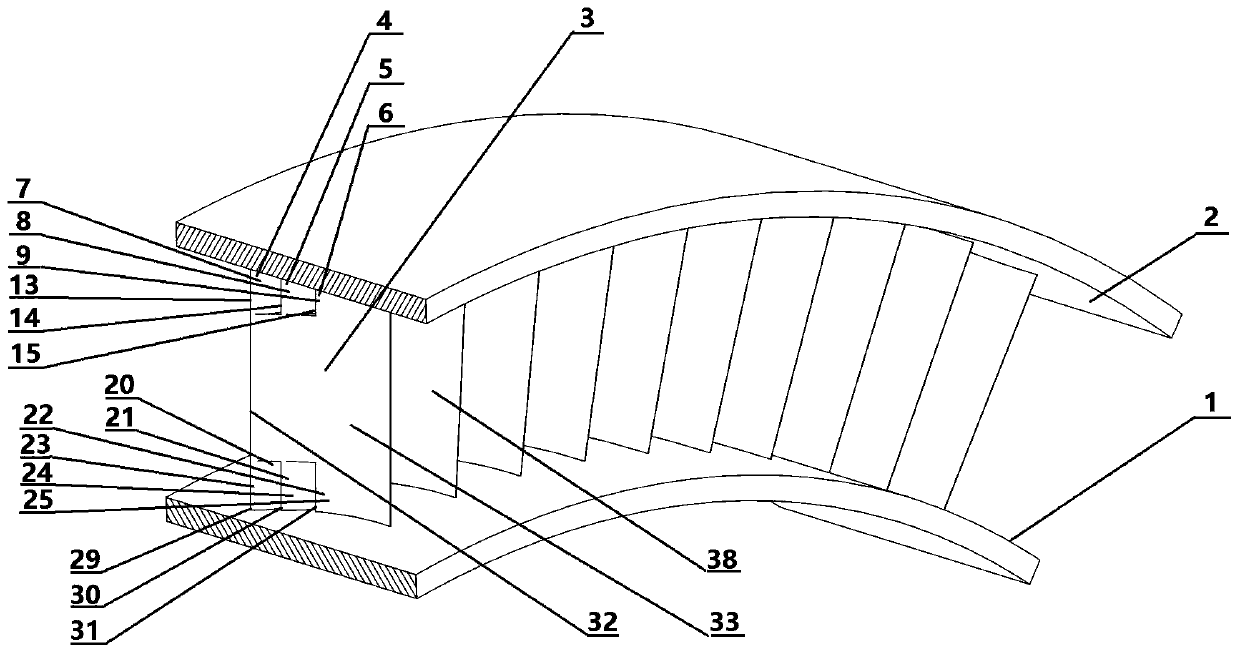

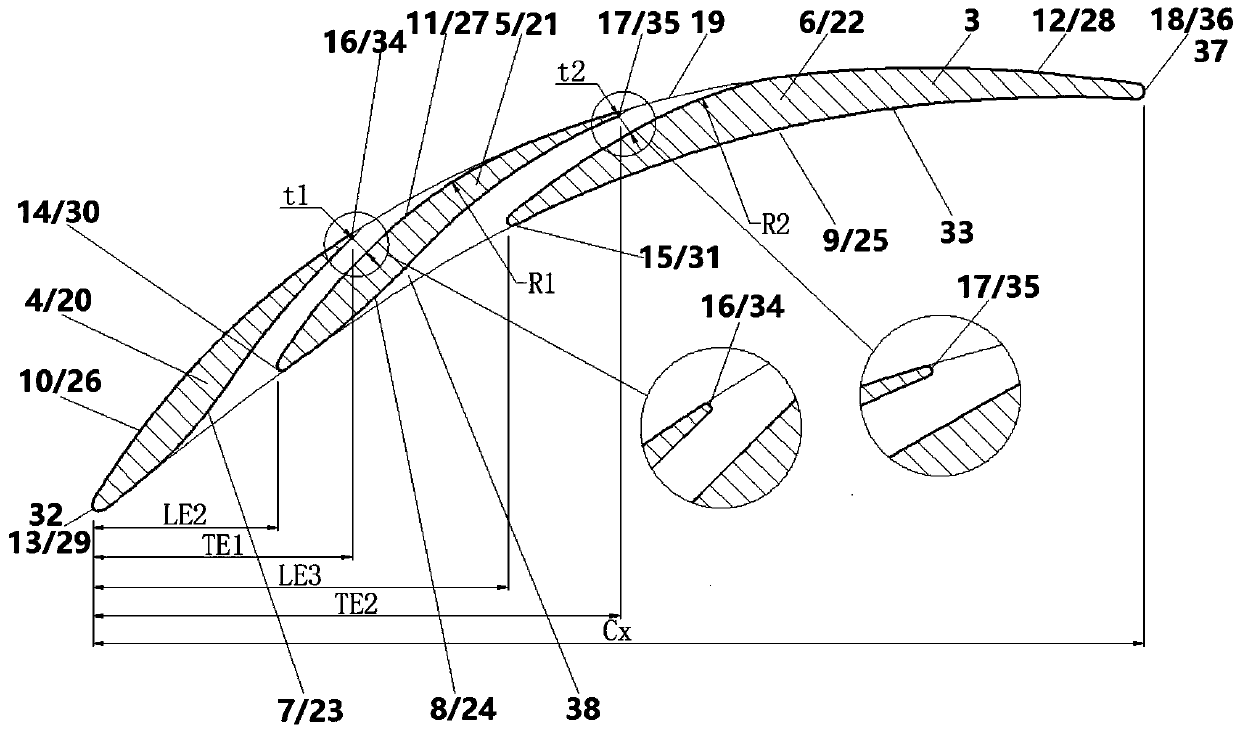

[0026] Such as figure 1 , figure 2 As shown, the large bending angle compressor stator blade of the present invention has a blade-shaped bending angle of 53 °, including the hub end wall 1, the casing end wall 2 and the stator blade 3, wherein the stator blade 3 is located between the casing end wall 2 and the hub Arranged in a circle between the end walls. The stator blade 3 is composed of the stator blade main body 38, small blades connected in series on the casing side one 4, two small blades connected in series on the casing side 21. Three small blades connected in series on the hub side are composed of three 22; small blades connected in series on the casing side one 4, small blades two connected in series on the casing side, three small blades connected in series on the casing side three 6 are used to connect the stator blade main body 38 and the casing end wall 2 , the airfoil section adopts continuous curvature airfoil design and has the same spanwise height, which ...

Embodiment 2

[0033] This embodiment is basically the same as Embodiment 1, the difference is that in this embodiment, the small blades connected in series on the casing side one 4 and the small blades connected in series on the hub side one 20 have different blade geometry, and the small blades connected in series on the casing side two 5 The second series small blade 21 on the hub side has a different airfoil geometry, the casing side series series small blade three 6 has a different blade geometry from the hub side series series small blade three 22, and the casing side series series small blades 4, 5, 6. The spanwise height is greater than the spanwise height of the small blades 20, 21, 22 connected in series on the hub side.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com