Pneumatic tire

A pneumatic tire, tire technology, applied in tire parts, tire tread/tread pattern, transportation and packaging, etc., to achieve superior wet performance, prevent rigidity from being reduced, and superior ride comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

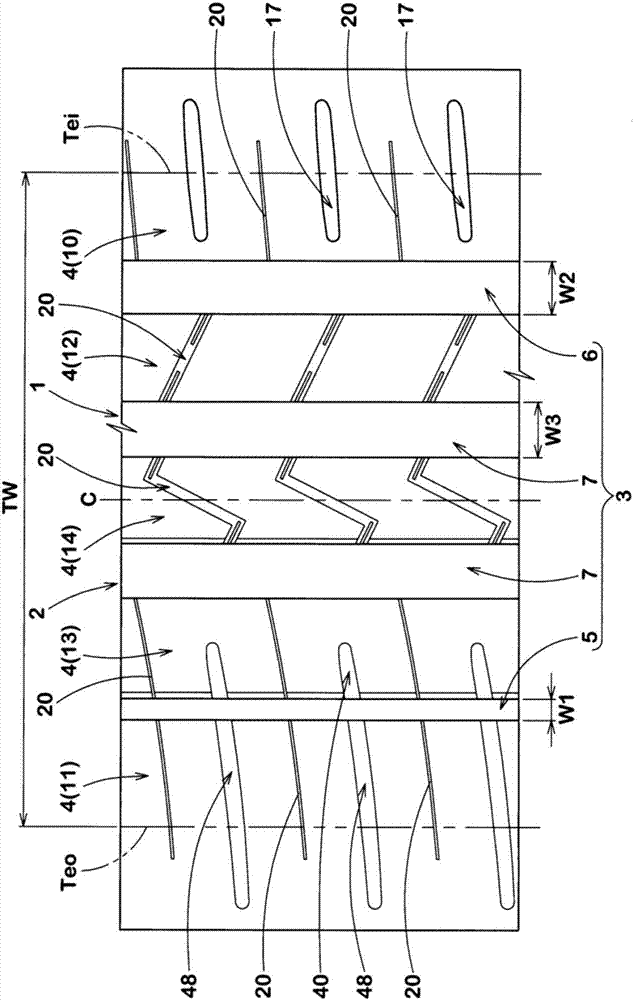

[0031] Hereinafter, one embodiment of the present invention will be described based on the drawings.

[0032] figure 1 It is a development view of the tread part 2 of the pneumatic tire 1 of this embodiment. The pneumatic tire 1 of the present embodiment is preferably implemented, for example, for passenger cars.

[0033] The tread portion 2 of the present embodiment has a tread pattern in which the direction of mounting on a vehicle is specified. The orientation to be attached to the vehicle is indicated on the sidewall portion, for example, by characters or symbols (illustration omitted).

[0034] Such as figure 1 As shown, the tread portion 2 has an outer tread end Teo positioned outside the vehicle when mounted on the vehicle, and an inner tread end Tei positioned inside the vehicle when mounted on the vehicle.

[0035] The outer tread end Teo and the inner tread end Tei are respectively defined as the tire axially outermost ground contact positions when a normal load ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com