Camera module testing method, camera module testing device and computer readable storage medium

A technology of a camera module and a test method, applied in the field of photography, can solve the problem of the attenuation of the resolution of the camera module, and achieve the effect of reducing the degree of attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

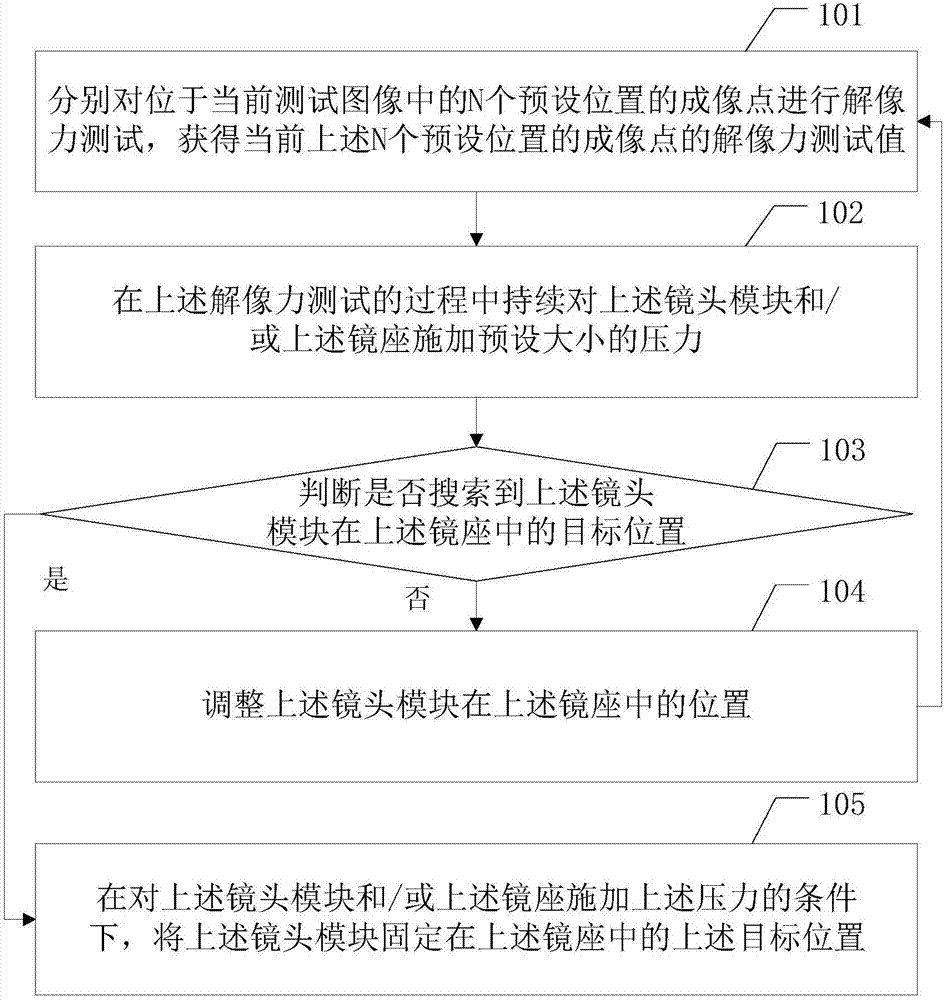

Method used

Image

Examples

Embodiment 2

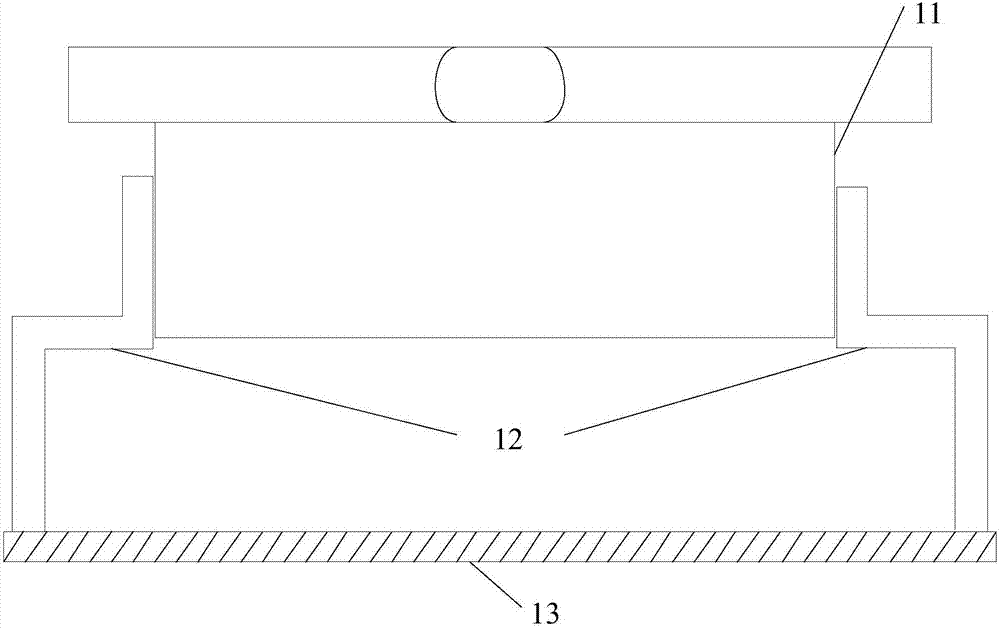

[0067] The embodiment of the present invention also provides a test device for a camera module, the camera module includes: a lens module and a lens holder for arranging the above-mentioned lens module, specifically, the structure of the camera module can be referred to Figure 1-a The description in the illustrated embodiment will not be repeated here. Such as image 3 As shown, the test device 300 of the camera module in the embodiment of the present invention includes:

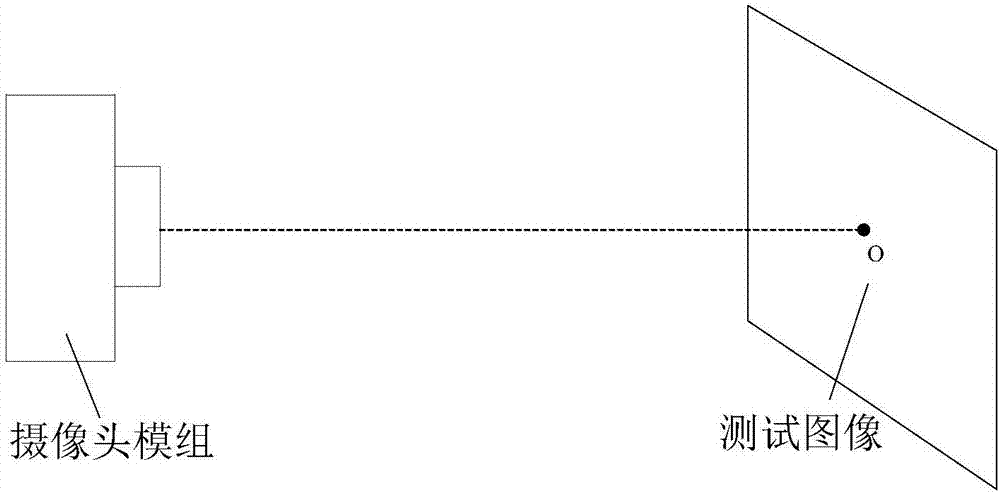

[0068] The resolution test unit 301 is configured to respectively perform a resolution test on the imaging points at N preset positions in the current test image, and obtain the current resolution test values of the imaging points at the N preset positions, wherein the current test image is determined by the current test image. The camera module is formed, and the above N is greater than or equal to 1;

[0069] The pressure applying unit 302 is configured to continuously apply a predetermined amount of p...

Embodiment 3

[0078] An embodiment of the present invention provides another testing device for a camera module, the camera module includes: a lens module and a lens holder for arranging the above-mentioned lens module, specifically, the structure of the camera module can be referred to Figure 1-a The description in the illustrated embodiment will not be repeated here. Such as Figure 4 As shown, the test device 400 of the camera module in the embodiment of the present invention includes: a memory 401, one or more processors 402 ( Figure 4 Only one of them is shown) and a computer program stored on the memory 401 and executable on the processor. Wherein: the memory 401 is used to store software programs and modules, and the processor 402 executes various functional applications and data processing by running the software programs and units stored in the memory 401 . Specifically, the processor 402 implements the following steps by running the above-mentioned computer program stored in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com