Worm gear case slip torque test system

A technology of torque testing and worm gear boxes, which is applied in the direction of force/torque/power measuring instruments, measuring devices, torque measurement, etc., can solve the problems of inaccuracy, high test cost, time-consuming, etc. precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

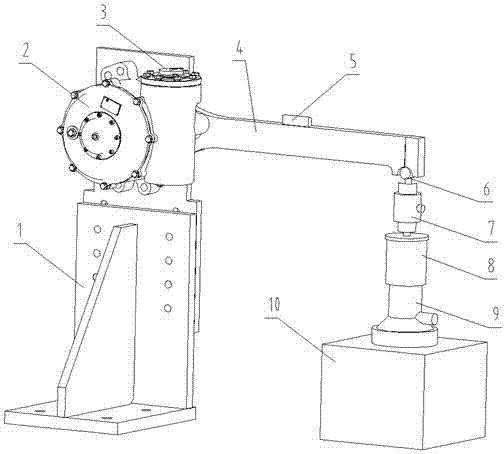

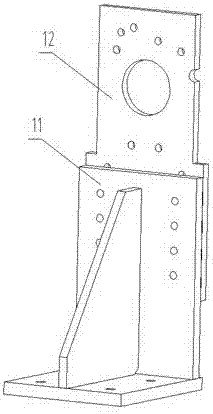

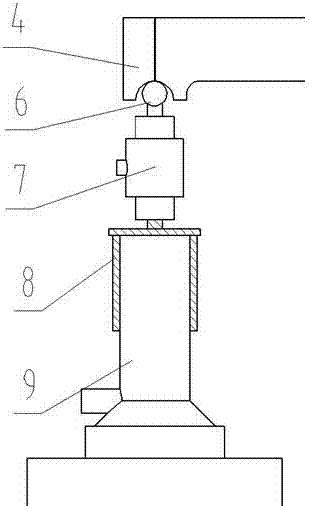

[0018] The present invention as figure 1 As shown, the worm gear box installation frame 1 is fixed on the ground and is used to install the worm gear box 2. The installation frame 1 includes a base 11 and a mounting plate 12. The mounting plate 12 and the base 11 are connected by bolts; the mounting plate 12 is connected by bolts Worm gear box 2, different mounting plates can be replaced to suit different worm gear boxes. The worm rotation indicating device 3 is installed on the worm shaft, and can follow the rotation of the worm shaft, and is used for adjusting and observing the rotation of the worm. The force arm 4 is used to transmit torque, one end is connected with the output shaft of the worm gear box 2, and the other end is in contact with the push rod 6, and the force transmitted by the push rod 6 acts on the output shaft of the worm gear box. Different force arms can be replaced to match different The size of the output shaft of the worm gear box. The spirit level 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com