3D printing consumable and application thereof

A technology of 3D printing and consumables, applied in the field of 3D printing, can solve the problems of printing failure, large fluctuations in outer diameter, size and shape, and large error of wire parameters, and achieve the effect of flexible application process, wide application and guaranteed efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The invention will be further described in detail below in conjunction with the drawings.

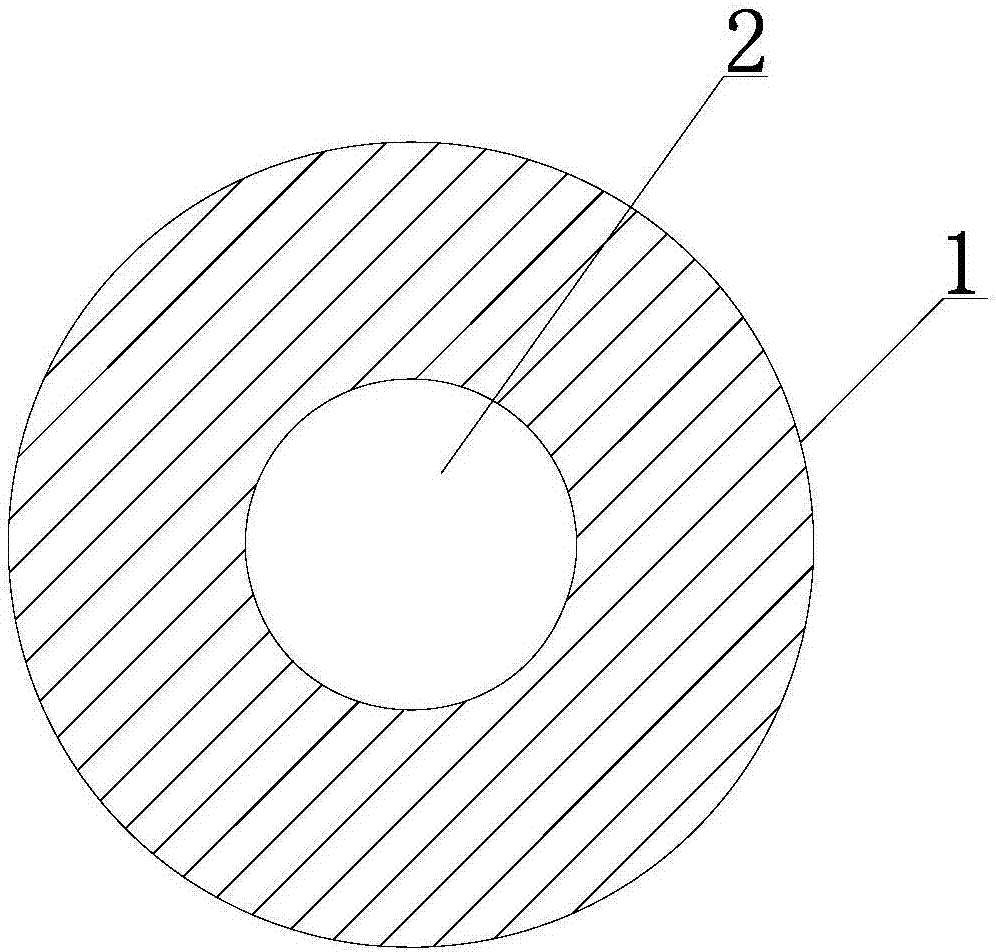

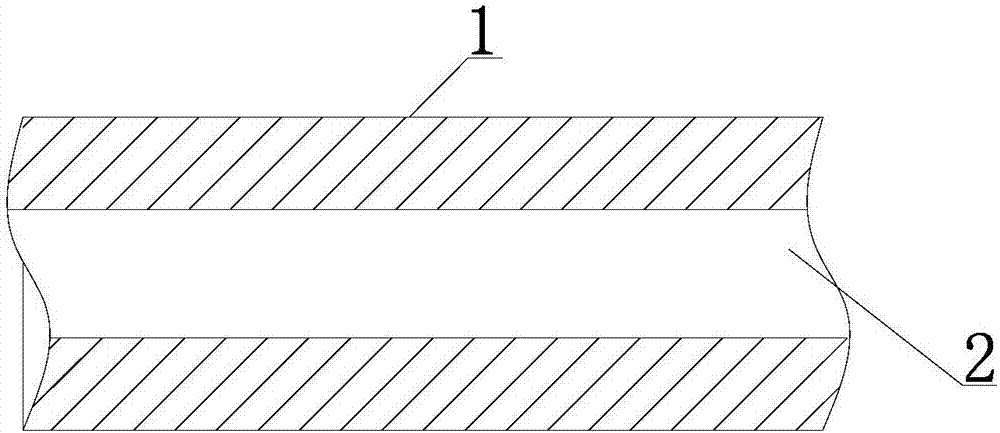

[0016] Such as Figure 1-2 As shown, a 3D printing consumable includes a 3D printing plastic line 1, and a vacuum core 2 is provided in the center of the 3D printing plastic line 1. The hollow core 2 is a middle pass. The 3D printing plastic line 1 is a finalized 3D printing plastic line 1.

[0017] An application of 3D printing consumables is as follows: (1) After extruding the 3D printing plastic through an external mold; (2) After that, using a vacuum rod to vacuum the center of the 3D printing plastic line 1 to form a hollow core 2; (3) 3D printing plastic line 1 that is shaped into a hollow core 2 through a water tank; (4) During the printing process, the position of the hollow core 2 can be used to interfere with the printing effect. If it is necessary to print medical products, manual intervention is used in the printing process, and the trace elements are transported to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com