Long-distance mass-batch wire laying device at region

A large-scale, long-distance technology, applied in cable laying equipment, transportation and packaging, transportation of filamentous materials, etc., can solve the problems of high production cost and lack of universality, reduce mechanical damage, improve labor efficiency, The effect of reducing the labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

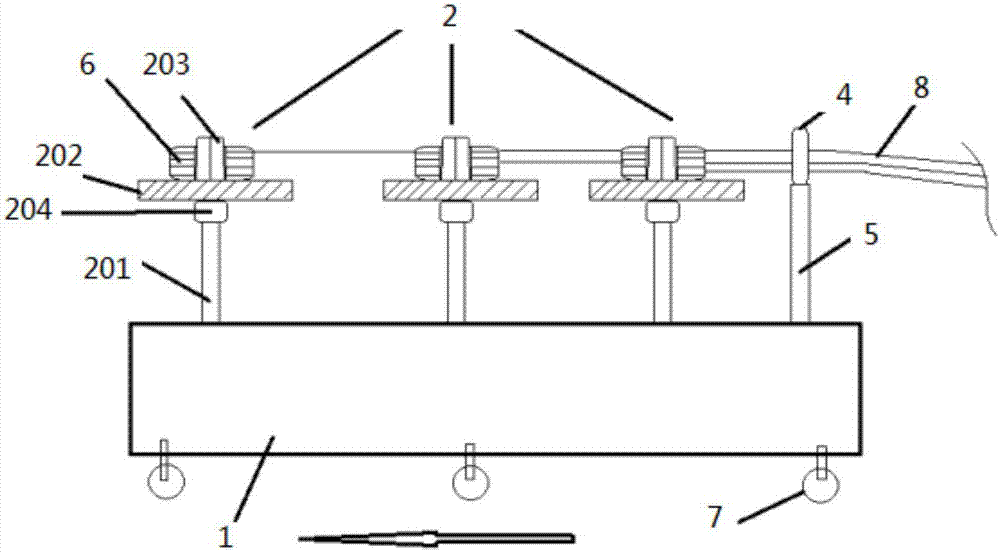

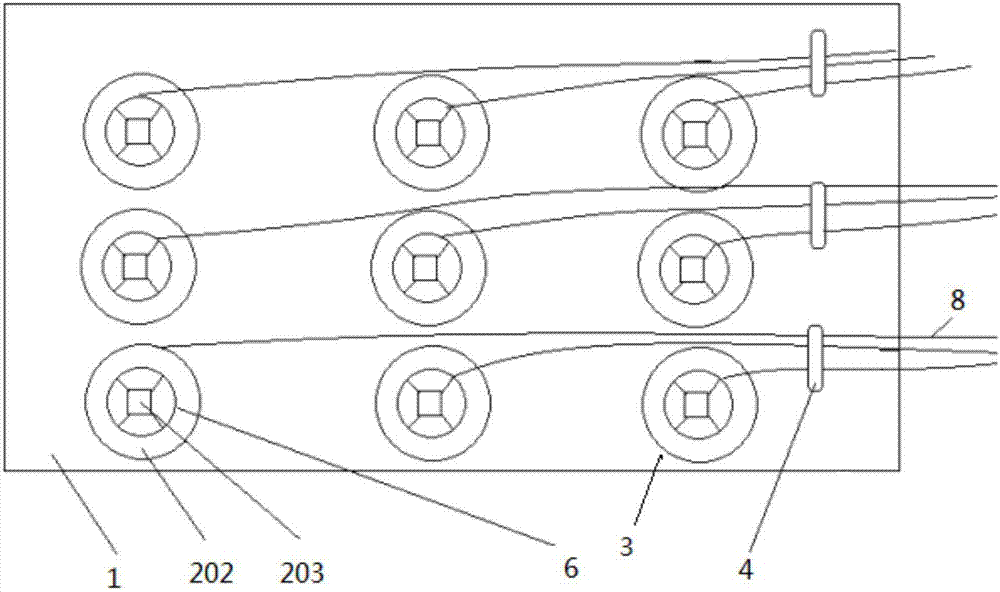

[0016] see figure 1 with figure 2 , the long-distance and large-volume wire laying device in intervals includes: a rack plate 1, a pay-off mechanism array composed of a pay-off mechanism 2 and a closing coil 4; the pay-off mechanism array is arranged vertically and horizontally on the frame The top of the disc 1; the closing coil 4 is fixed on the frame disc 1 through the connecting rod 5, and is located at the edge of each line pay-off mechanism 2; the described pay-off mechanism includes a support column 201, a wire reel tray 202 and a rotating shaft 203; the bottom of the support column 201 is fixed on the frame disc 1, and the wire tray tray 202 is connected with the upper end of the support column 201 through a rotating member 204 such as a bearing; The outer surface of the rotating shaft 203 is provided with a reel positioning mechanism that cooperates with the outer surface of the reel 6, and the lower end of the rotating shaft 203 is fixed on the upper surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com