Light material high-station automatic feeding device

An automatic supply, high-station technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of cross-operation between operators and logistics personnel, affecting production efficiency, and long transportation routes, so as to avoid personnel cross-operation, The effect of reducing the transportation distance and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the embodiments shown in the accompanying drawings.

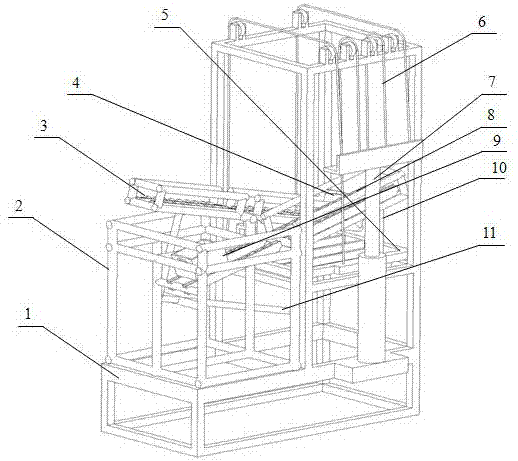

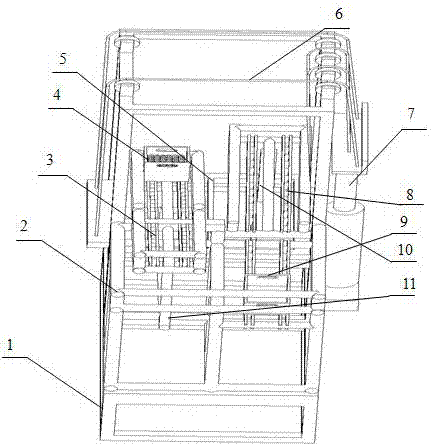

[0015] The device of the present invention is composed of a base frame, a material conversion table, a feeding slideway, a material loading box, a material lifting platform, a traction wire rope, a cylinder, a discharge slideway, an empty material box, a push rod and a lever connecting rod. The bottom of the device adopts a rectangular base frame 1, and a material transfer table 2 is placed on the base frame. One side of the material transfer table is a feeding slideway 3. The material loading box 4 is placed on the feeding slideway to wait for feeding. The material lifting table 5 is pulled by a wire rope. 6 is connected to the cylinder 7, the side of the material lifting platform is the discharge slide 8, the returned empty material box 9 is placed above the discharge slide, the ejector rod 10 is placed below the discharge slide, and the lev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com