an automatic stamping machine

A punching machine, automatic technology, applied in the directions of feeding devices, manufacturing tools, positioning devices, etc., can solve the problems of dangerous manual operation, low production efficiency, waste of manpower, etc., to improve stamping accuracy, high production efficiency, and safety. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

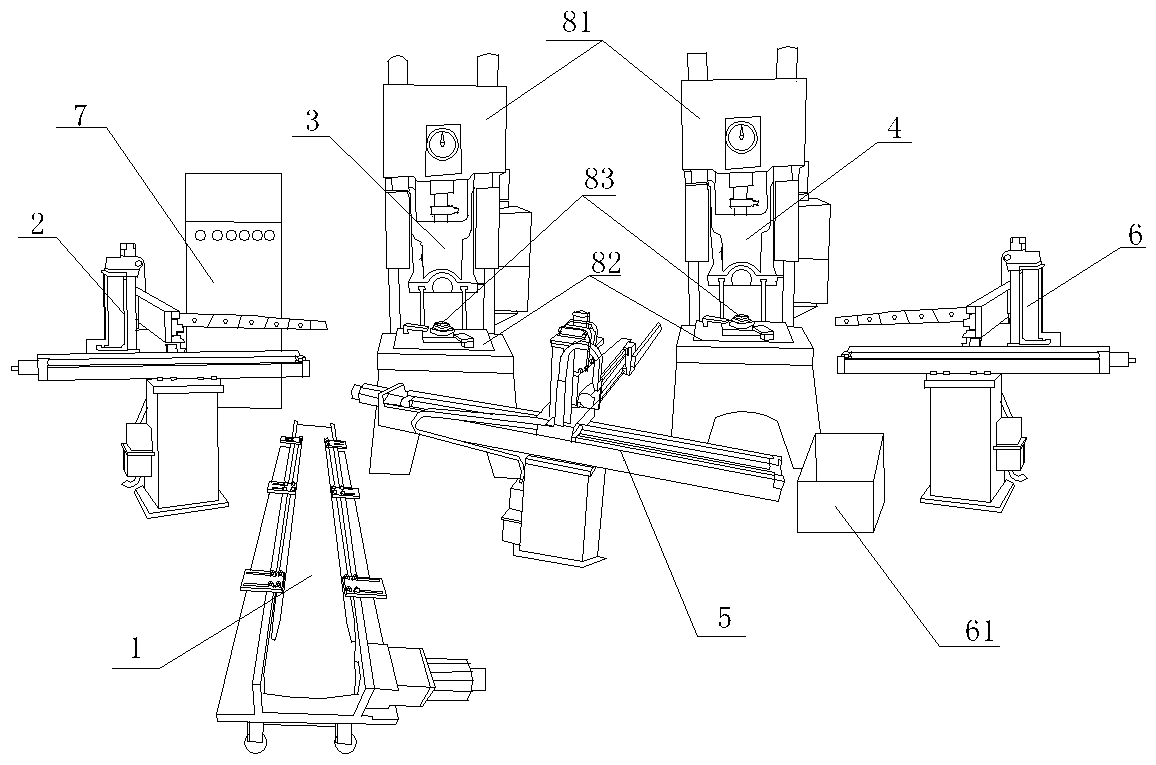

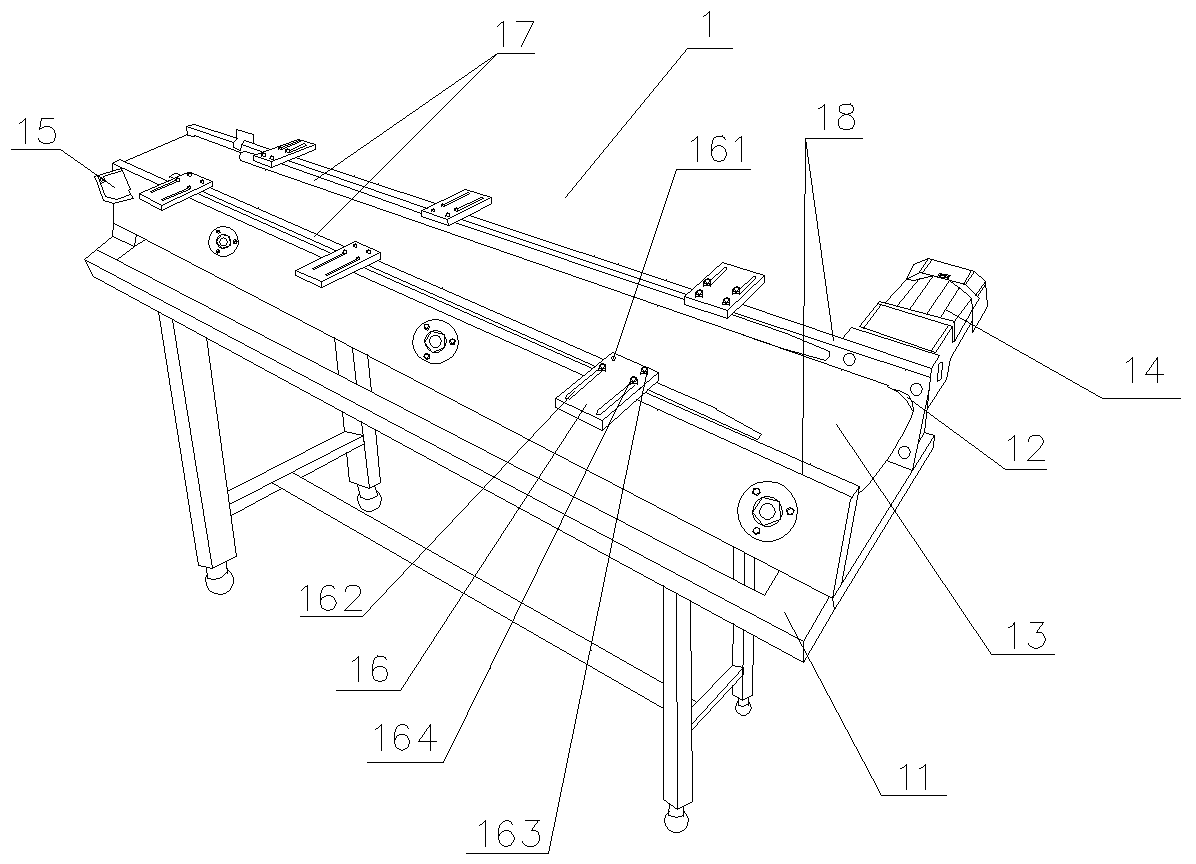

[0022] Embodiment one: if Figure 1-3 Shown is a schematic structural diagram of an embodiment of an automatic stamping machine provided by the present invention, including at least one stamping device, and also includes an automatic feeding device 1, at least one three-axis feeding manipulator, three-axis reclaiming manipulator 6 and an automatic control system 7, The three-axis feeding manipulator is located on the left side of the stamping device, the three-axis retrieving manipulator 6 is located on the right side of the stamping device, the automatic feeding device 1 is located in front of the three-axis feeding manipulator, and the three-axis reclaiming manipulator 6 is provided with a storage basket 61, automatic control system 7 Control the automatic feeding device 1, the three-axis feeding manipulator, the stamping device and the three-axis reclaiming manipulator 6. Automatically load, take out, stamp and unload in an orderly and coherent manner. The three-axis feedin...

Embodiment 2

[0025] Embodiment two: if Figure 4-5 As shown, the punching device in Embodiment 1 includes a first punching device 3 and a second punching device 4, and the three-axis feeding manipulator includes the first three-axis feeding manipulator 2 and the second three-axis feeding manipulator 5, the first punching device 3 and the second three-axis feeding manipulator. The second stamping device 4 is arranged side by side, the first three-axis feeding manipulator 2 is located on the left side of the first stamping device 3, the three-axis retrieving manipulator 6 is located on the right side of the second stamping device 4, and the second three-axis feeding manipulator 5 is located on the first stamping In front of the device 3 and the second stamping device 4, the automatic feeding device 1 is located on the left side of the second three-axis feeding manipulator 5. The workpiece punched by the first punching device is a workpiece with a rectangular hole 19 , and the second punching...

Embodiment 3

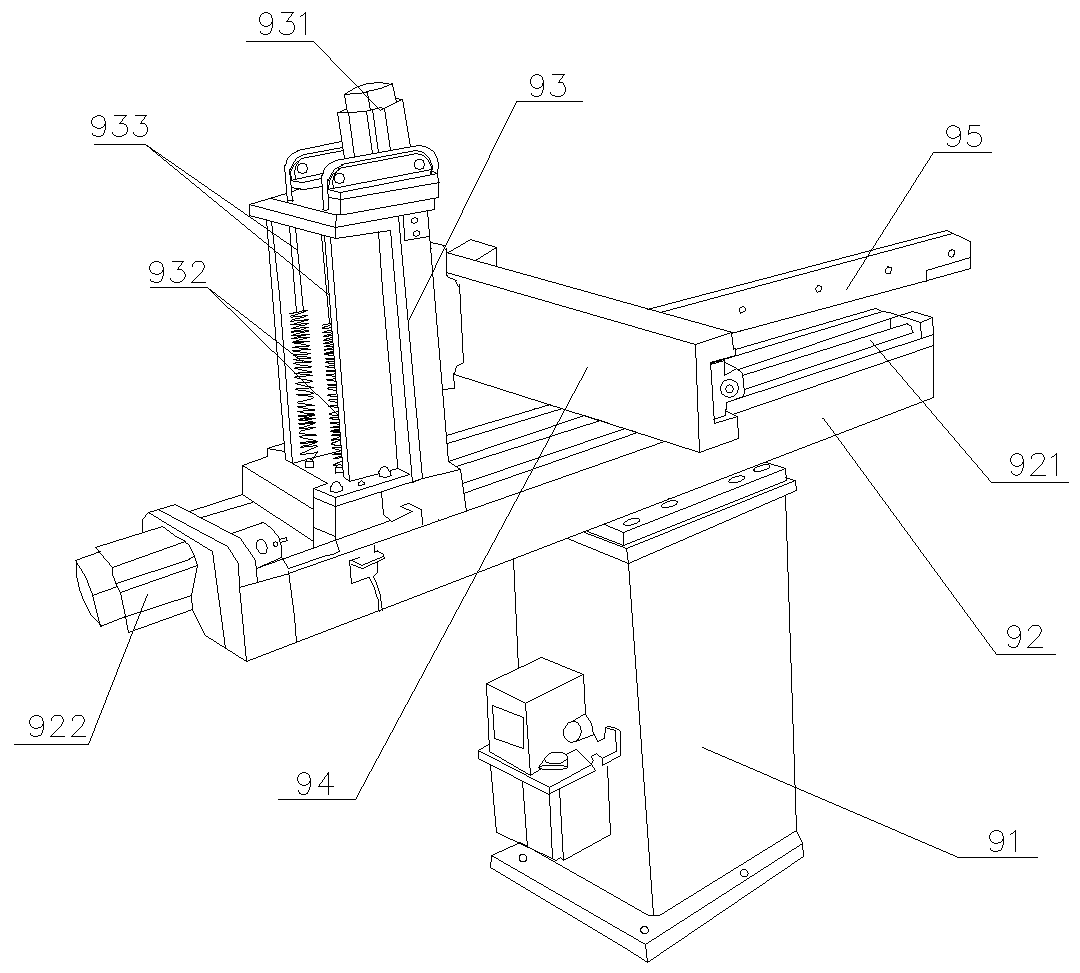

[0026] Embodiment three: the lifting chute 93 in embodiment one also includes a longitudinal chute stabilizing device, and the longitudinal chute stabilizing device includes two springs 932 arranged vertically and parallel to each other, and one end of the spring 932 is connected to the left side of the lifting chute 93. The bottom is connected, and the other end of spring 932 is connected with chain 933, and chain 933 passes the sprocket wheel that is provided with on the top of lifting chute 93 from the left side of lifting chute 93 and then winds to the right side of lifting chute 93 and with the longitudinal sliding Groove 94 connection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com