Surface crack identification method based on fused time frequency characteristics

A recognition method and technology of time-frequency characteristics, which are applied in image data processing, instruments, calculations, etc., to achieve the effect of suppressing noise, small interference, and accurate crack location.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

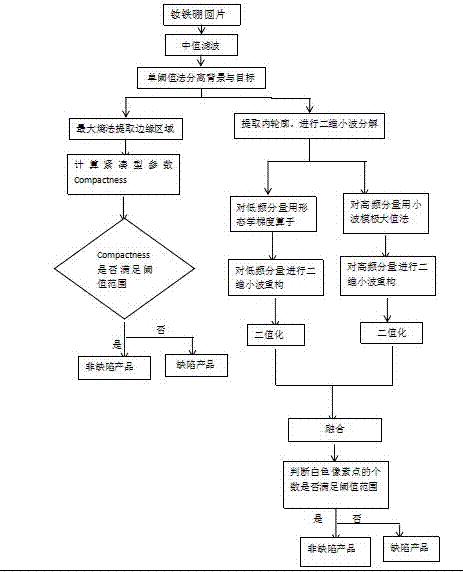

[0024] A method for identifying cracks on the surface of NdFeB discs with time-frequency features, comprising the following steps:

[0025] Step 1: Obtain real-time images of NdFeB wafers on the assembly line through visual equipment;

[0026] Step 2: Carry out median filter preprocessing on the image to eliminate noise. Specific steps are as follows:

[0027] 2.1 Move the 3*3 filter template in the image, and make the center of the filter template coincide with a certain pixel position of the image;

[0028] 2.2 Read the gray value of each corresponding pixel in the template;

[0029] 2.3 Arrange these gray values in ascending order;

[0030] 2.4 The output of two-dimensional median filtering is g(x,y)=med{f(x-k,y-l),(k,l∈W)}, where f(x,y) and g(x,y) are respectively Original image pixels and processed image pixels. W is a two-dimensional template, which is a 3*3 area.

[0031] Step 3, use the single threshold segmentation method to separate the background and the tar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com